SLAAEF5 March 2024 MSPM0G1505 , MSPM0G1505 , MSPM0G1506 , MSPM0G1506 , MSPM0G1507 , MSPM0G1507 , MSPM0L1303 , MSPM0L1303 , MSPM0L1304 , MSPM0L1304 , MSPM0L1304-Q1 , MSPM0L1304-Q1 , MSPM0L1305 , MSPM0L1305 , MSPM0L1305-Q1 , MSPM0L1305-Q1 , MSPM0L1306 , MSPM0L1306 , MSPM0L1306-Q1 , MSPM0L1306-Q1

- 1

- Abstract

- Trademarks

- 1Introduction

- 2Algorithm Introduction

- 3Gauge GUI Introduction

- 4MSPM0 Gauge Evaluation Steps

- 5MSPM0 Gauge Solutions

- 6References

4.4.1 Detection Data Input Mode

In this mode, you need the MSPM0 Gauge board and a real battery for test. The detection data (Vcell, Icell, Tcell) comes from the real detected signals. The GUI can help to record the battery running data for further analysis.

For software setting, you need to download the gauge code to the launchpad after changing the detection mode to "DETECTION_DATA_INPUT" in "Gauge_UserConfig.h".

Figure 4-11 Detection Data Input Mode

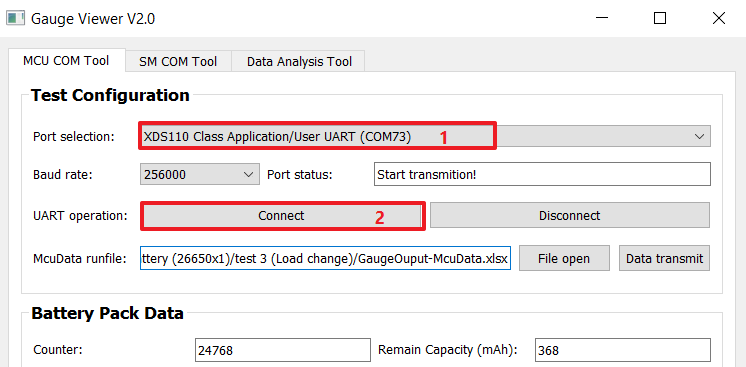

Figure 4-11 Detection Data Input ModeFor GUI control, you only need to select the right port with the name XDS110 Class Application/User UART and then click the connect button. If the MCU already works, you will see the test data at MCU Test Data block. After you click the disconnect button, the data will be saved in excel type under the same address of GUI, with the name "YYYY-MM-DD-HH-MM-McuData.xlsx".