SNAA390 july 2023 LMK6C , LMK6D , LMK6H , LMK6P

- 1

- Abstract

- Trademarks

- 1Introduction

- 2Test Standards and Test Setup

- 3Sinusoidal Vibration, Random Vibration, and Mechanical Shock Tests

- 4Comparison of BAW Oscillator Vibration Performance With Crystal Oscillator

- 5Summary

- 6References

3.2.2 Results From Random Vibration Test

The plots shown in this section are captured before, during, and after the random vibration test, which are tested following the MIL-STD-883F method 2026C.

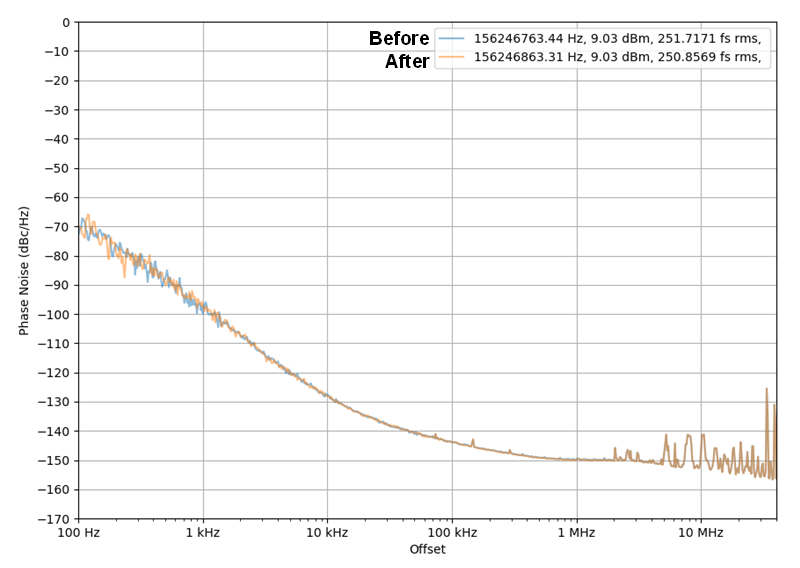

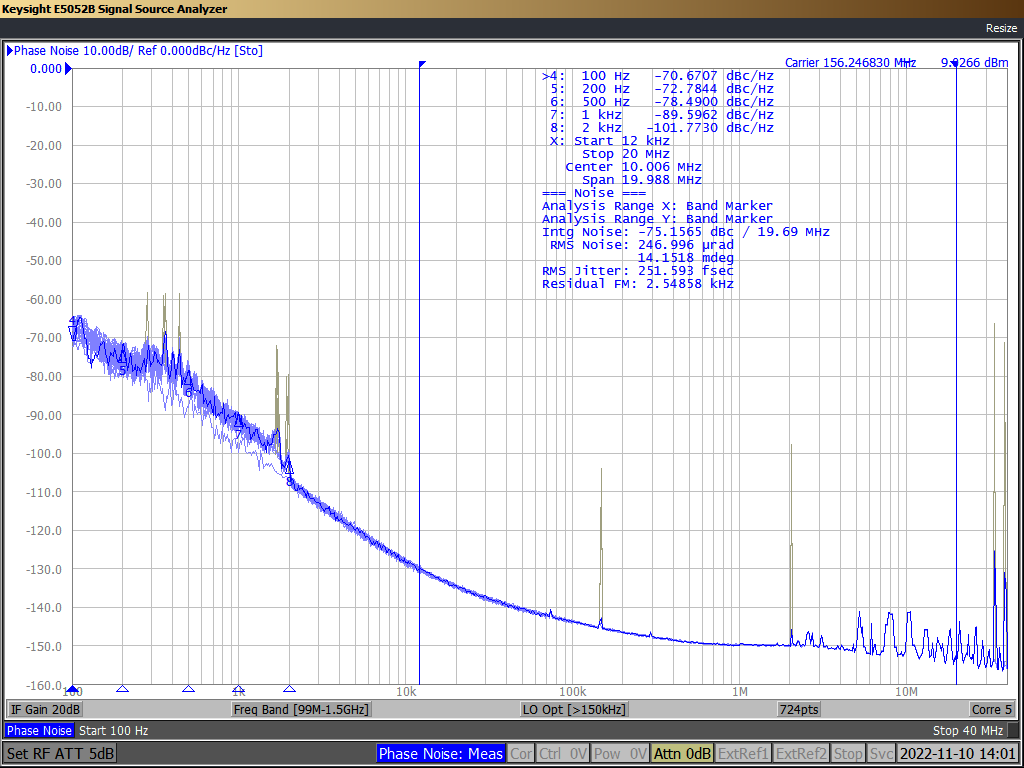

The capture data for the Z-axis movement of the DLE 4-pin (LVCMOS) oscillator is shown in Figure 3-15 and Figure 3-16.

Figure 3-15 Plot of Before and After

Vibration Test on 4-pin DLE (LVCMOS)

Figure 3-15 Plot of Before and After

Vibration Test on 4-pin DLE (LVCMOS) Figure 3-16 Capture During Vibration

of the 4-pin DLE (LVCMOS)

Figure 3-16 Capture During Vibration

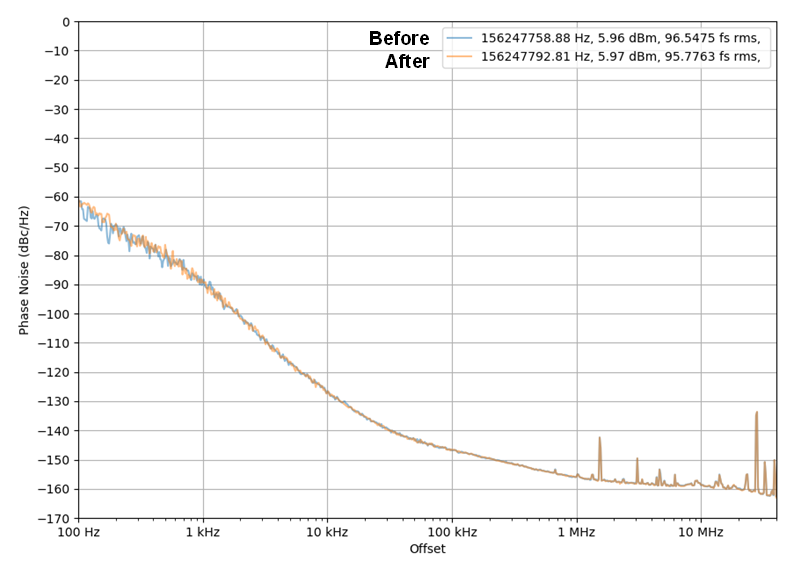

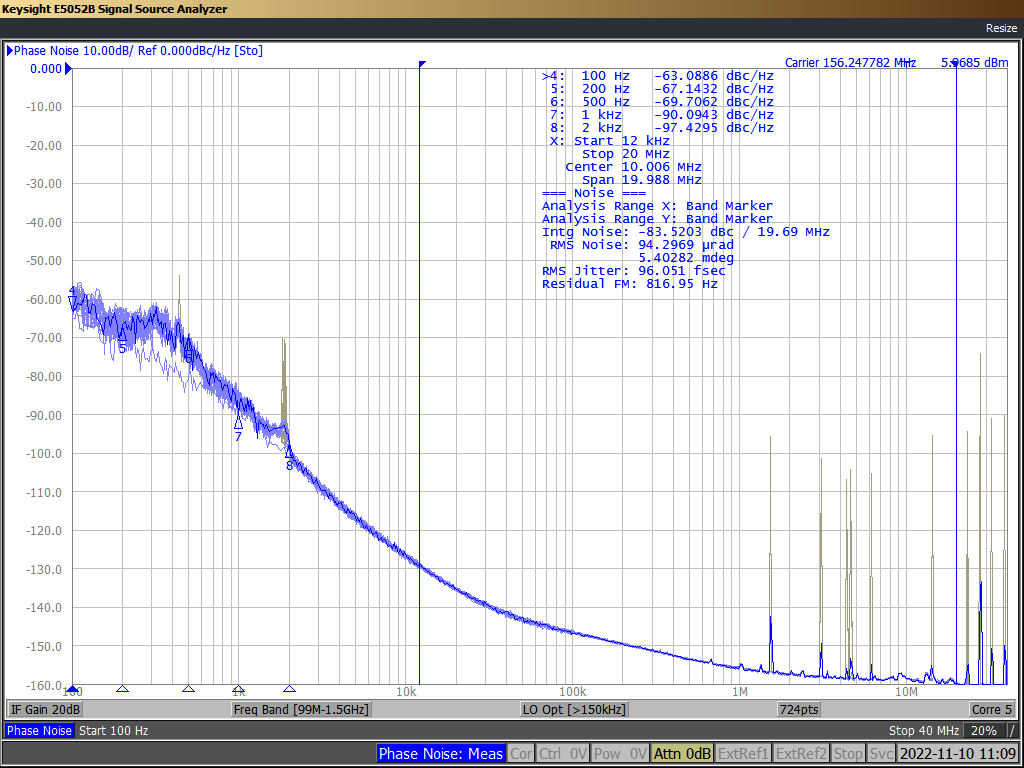

of the 4-pin DLE (LVCMOS)The capture data for the Z-axis movement of the DLE 6-pin (LVPECL) oscillator is shown in Figure 3-17 and Figure 3-18.

Figure 3-17 Plot of Before and After

Vibration Test on 6-pin DLE (LVPECL)

Figure 3-17 Plot of Before and After

Vibration Test on 6-pin DLE (LVPECL) Figure 3-18 Capture During Vibration

Test on 6-pin DLE (LVPECL)

Figure 3-18 Capture During Vibration

Test on 6-pin DLE (LVPECL)The preceding plots show that the performance of the BAW Oscillator is robust during and after the vibration and the jitter performance is not degraded.