SPRUHW1A June 2014 – October 2021 TMS320F28052-Q1 , TMS320F28052M , TMS320F28052M-Q1 , TMS320F28054-Q1 , TMS320F28054M , TMS320F28054M-Q1

- 1Read This First

- 1 F2805xM InstaSPIN-MOTION Enabled MCUs

- 2InstaSPIN-MOTION Key Capabilities and Benefits

- 3InstaSPIN-MOTION Block Diagrams

- 4Application Examples

- 5Evaluating InstaSPIN-MOTION Performance

- 6Microcontroller Resources

5.2.1 Disturbance Rejection

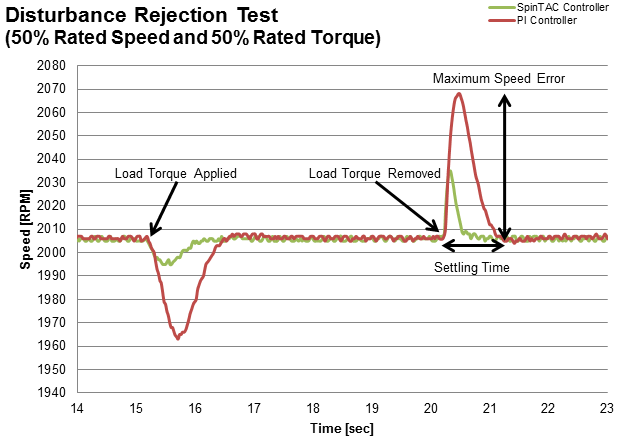

Disturbance rejection tests the controller's ability to compensate for external disturbances, which impact the motor speed. In the disturbance rejection test, a load torque is applied to the system, held on for a short period of time, and then removed from the system. Figure 6-3 is an example of a disturbance rejection test. The response of the controller is measured using the maximum speed error and settling time. The maximum speed error shows the deviation from the goal speed, and is an indication of how aggressively your controller is tuned. Aggressive tuning produces a low maximum error. In Figure 6-3 the PI controller presents a greater maximum speed error than the SpinTAC controller, indicating that the SpinTAC controller is more responsive in compensating for system error.

Settling time refers to the amount of time from the point when the disturbance happens until the speed returns to a fixed band around the goal speed. This is also an indication of how aggressively your control loop is tuned. If the controller is tuned too aggressively it will have a long settling time because it will oscillate around the goal speed before settling. In Figure 6-3, the PI controller has a longer setting time that the SpinTAC controller. Note that there is very little oscillation in either controller as they settle back to the goal speed.

Figure 5-3 Disturbance Rejection Test of Maximum Speed Error and Settling Time

Figure 5-3 Disturbance Rejection Test of Maximum Speed Error and Settling Time

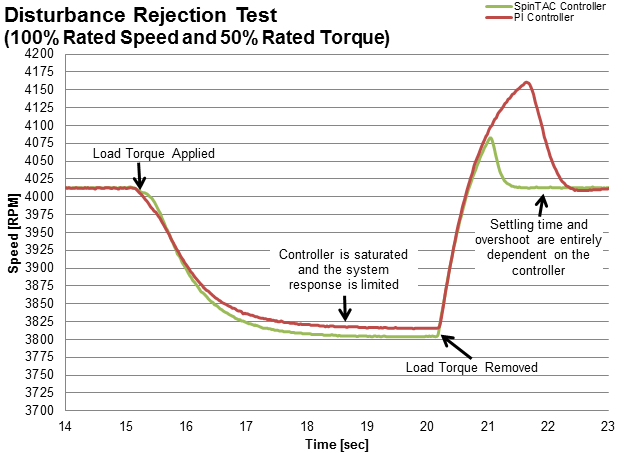

There may be a difference in settling time when loads are applied to the system, and when loads are removed from the system. When a load is applied to a motor, the controller may reach saturation, at which point the controller's output is limited. However, when the load is removed, the motor transitions from a loaded state to zero load. The settling time and overshoot is entirely dependent upon the controller. Figure 6-4 shows an example of this case where the controller was placed into saturation.

When performing disturbance rejection testing it is important to test at multiple speed and load combinations. Speed controllers have different performance characteristics when placed into different situations. In order to properly evaluate the effectiveness of your speed controller, tests should be performed across the entire application operating range. The test results will indicate whether the controller will meet the application specifications, or whether the controller needs to be tuned multiple times for different operating points (gain scheduling). The following test results were obtained for nine different speed and load combinations in order to test a wide range of operation.

It is also important to be able to create repeatable disturbances. This can be accomplished using a dynamometer or a disturbance motor. Creating repeatable disturbance is an important factor when evaluating multiple controllers. If test conditions cannot be replicated, it is difficult to adequately compare the responses of multiple controllers.

Figure 5-4 Disturbance Rejection Test with Controller Saturation

Figure 5-4 Disturbance Rejection Test with Controller Saturation

For the test results shown in Table 6-2 and Table 6-3, a disturbance load profile was created that applied 25%, 50%, and 100% of rated torque to the motor. The test compared the performance of the SpinTAC speed controller to a standard PI controller, and the following parameters were measured for each:

- Average Recovery Time (from the point of disturbance until within 2% of the target speed): The average recovery time was measured when the load was applied and when the load was removed from the system.

- Absolute Average Speed Error: The positive or negative deviation from the goal speed when a system disturbance is introduced.

- Maximum Speed Error: The maximum deviation from goal speed when a disturbance is introduced.

| 1000 rpm | 2000 rpm | 4000 rpm | |||||||

|---|---|---|---|---|---|---|---|---|---|

| SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | |

| 25% rated torque | |||||||||

| Avg Recovery Time(s) - load applied | 1.34 | 1.84 | 27.34 | 1.20 | 1.67 | 28.27 | 0.85 | 1.79 | 52.46 |

| Avg Recovery Time(s) - load removed | 0.43 | 0.93 | 53.29 | 0.41 | 0.89 | 53.55 | 0.54 | 1.02 | 46.82 |

| Abs Avg Error (rpm) | 3.06 | 4.16 | 26.44 | 5.98 | 6.63 | 9.74 | 12.23 | 12.42 | 1.53 |

| Avg Max Error (rpm) | 17 | 29 | 41.38 | 16 | 27 | 40.74 | 18 | 26 | 30.77 |

| 50% rated torque | |||||||||

| Avg Recovery Time(s) - load applied | 1.01 | 1.33 | 23.81 | 1.01 | 1.45 | 30.34 | 4.98 | 5.04 | 1.19 |

| Avg Recovery Time(s) - load removed | 0.51 | 1.04 | 51.30 | 0.56 | 1.06 | 46.52 | 1.33 | 2.54 | 47.20 |

| Abs Avg Error (rpm) | 3.7 | 7.9 | 53.16 | 6.21 | 10.2 | 39.12 | 81.92 | 87.66 | 6.55 |

| Avg Max Error (rpm) | 36 | 71 | 49.30 | 35 | 69 | 49.28 | 197 | 185 | -6.49 |

| 100% rated torque | |||||||||

| Avg Recovery Time(s) - load applied | 0.76 | 1.20 | 36.67 | 0.78 | 1.16 | 32.73 | 4.98 | 5.08 | 1.95 |

| Avg Recovery Time(s) - load removed | 0.40 | 1.00 | 59.84 | 0.52 | 1.02 | 48.89 | 1.90 | 3.12 | 39.09 |

| Abs Avg Error (rpm) | 5.4 | 15.39 | 64.91 | 7.99 | 17.54 | 54.45 | 345.42 | 360.74 | 4.25 |

| Avg Max Error (rpm) | 87 | 158 | 44.94 | 80 | 151 | 47.02 | 829 | 837 | 0.96 |

| 750 rpm | 1500 rpm | 3000 rpm | |||||||

|---|---|---|---|---|---|---|---|---|---|

| SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | |

| 25% rated torque | |||||||||

| Avg Recovery Time(s) - load applied | 0.69 | 1.52 | 54.34 | 0.60 | 1.36 | 57.96 | 0.60 | 1.35 | 52.87 |

| Avg Recovery Time(s) - load removed | 0.42 | 1.12 | 61.75 | 0.40 | 1.03 | 61.58 | 0.41 | 1.01 | 59.01 |

| Abs Avg Error (rpm) | 1.97 | 3.81 | 48.13 | 3.05 | 5.25 | 41.90 | 6.16 | 9.08 | 32.12 |

| Avg Max Error (rpm) | 37 | 47 | 21.28 | 36 | 47 | 23.40 | 38 | 49 | 22.45 |

| 50% rated torque | |||||||||

| Avg Recovery Time(s) - load applied | 0.35 | 1.31 | 72.97 | 0.33 | 1.33 | 76.23 | 0.36 | 1.13 | 67.07 |

| Avg Recovery Time(s) - load removed | 0.44 | 1.36 | 67.32 | 0.40 | 1.25 | 68.02 | 0.364 | 1.14 | 67.33 |

| Abs Avg Error (rpm) | 2.67 | 5.91 | 54.87 | 3.86 | 7.13 | 45.89 | 6.89 | 11.14 | 38.19 |

| Avg Max Error (rpm) | 76 | 96 | 20.83 | 74 | 95 | 22.11 | 76 | 97 | 21.65 |

| 100% rated torque | |||||||||

| Avg Recovery Time(s) - load applied | 0.56 | 2.26 | 75.09 | 0.5 | 2.14 | 76.68 | 4.98 | 5.06 | 1.58 |

| Avg Recovery Time(s) - load removed | 0.38 | 1.16 | 66.78 | 0.4 | 0.92 | 55.93 | 0.44 | 0.74 | 40.60 |

| Abs Avg Error (rpm) | 8.64 | 57.98 | 85.09 | 9.54 | 59.95 | 84.09 | 94.25 | 103.74 | 9.15 |

| Avg Max Error (rpm) | 440 | 697 | 36.87 | 440 | 665 | 33.83 | 585 | 646 | 9.44 |