SPRUHW1A June 2014 – October 2021 TMS320F28052-Q1 , TMS320F28052M , TMS320F28052M-Q1 , TMS320F28054-Q1 , TMS320F28054M , TMS320F28054M-Q1

- 1Read This First

- 1 F2805xM InstaSPIN-MOTION Enabled MCUs

- 2InstaSPIN-MOTION Key Capabilities and Benefits

- 3InstaSPIN-MOTION Block Diagrams

- 4Application Examples

- 5Evaluating InstaSPIN-MOTION Performance

- 6Microcontroller Resources

5.3.2 Reference Tracking

Reference tracking tests how well the controller follows a changing position target. The two metrics to evaluate in these tests are the maximum error and the absolute average error. The maximum position error shows how much the controller overshoots while changing speeds. This is an indication of how aggressively your controller is tuned. If you controller is not tuned aggressively enough, the speed will overshoot the target, and will take a long time to recover. If the controller is tuned too aggressively it will overshoot, and then oscillate as it settles on the position target. If the controller is correctly tuned, it will minimally overshoot and then smoothly return to the position target.

Absolute average error is an average of the absolute value of the instantaneous position error over the entire profile. This measure shows the amount of deviation throughout the entire profile. It takes into account all of the little errors as the motor is running. If the controller is tuned too aggressively it will result in larger absolute average error because the controller will be oscillating throughout the profile. If the controller is not tuned aggressively enough, it will result in a larger absolute average error because it is continuously falling behind the commanded profile.

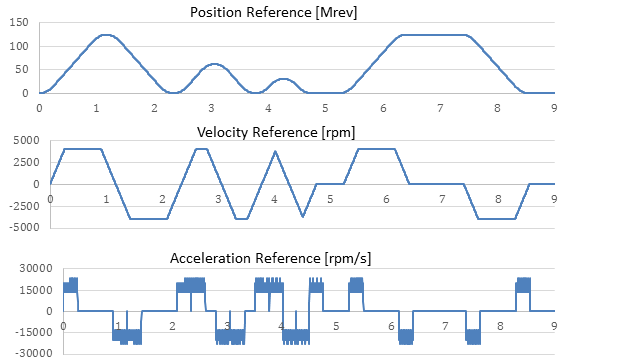

A position tracking profile was created to exercise the motor in a repeatable a pattern. The profile was used to compare the performance of SpinTAC Position Control and the PI control system. The profile included quick transitions as well as gentle sweeping transitions. Figure 6-11 is a plot of the reference profile that was used in the tests.

Figure 5-11 Position

Profile Used During Reference Tracking Test

Figure 5-11 Position

Profile Used During Reference Tracking Test

The blocked off area has an additional plot that will highlight the differences between SpinTAC and PI controllers.

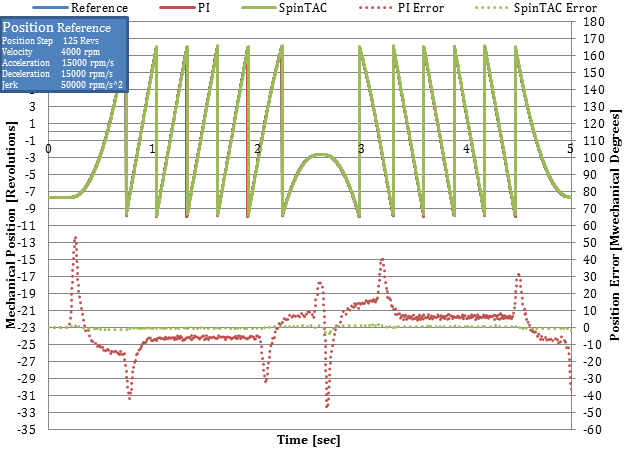

Figure 6-12 is the first part of the position reference tracking test. The red line at the bottom of the chart is the PI position error. The green line is the SpinTAC position error. Notice that the PI position error is much larger when making transitions and it also has an offset when in the constant velocity section of the profile. While SpinTAC has no issues with tracking the profile and has much less error than the PI controller.

Figure 5-12 PI Error

During Position Tracking

Figure 5-12 PI Error

During Position Tracking

It is important to test multiple speeds and accelerations in your position profile as well as multiple different loads. Position controllers have different performance characteristics when placed into different situations. In order to properly evaluate the effectiveness of your controller, tests should be conducted across the entire application range. This includes when you design the profile for testing. Care needs to be taken to ensure that the application speeds and accelerations are built into the position profile. The results of these tests will indicate whether the controller will meet the application specifications, or if the controller needs to be tuned multiple times for different operating points. You should notice in Figure 6-11 that there is a wide range of speeds and accelerations that are tested.

It is also important to be able to create repeatable profiles. Creating a repeatable profile can be done using SpinTAC Move and SpinTAC Plan (the InstaSPIN-FOC and InstaSPIN-MOTION User's Guide provides detailed information on SpinTAC Move and SpinTAC Plan, and lab projects are available in the MotorWare repository). Repeatable profiles are required if position controllers are being compared. A repeatable profile ensures that the controllers will be tested using the same reference in the same order and for the same length of time, and that test conditions are as identical as possible. The profile for this test was made using SpinTAC Move and SpinTAC Plan.

The following parameters were measured:

- Absolute Average Position Error - deviation (in mechanical degrees) from the target over the entire position profile.

- Maximum Position Error - maximum deviation (in mechanical degrees) from the goal position during the position profile.

| Trapezoidal Curve | st-Curve | |||||

|---|---|---|---|---|---|---|

| SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | SpinTAC | PI | SpinTAC Advantage (percentage improvement over PI) | |

| Teknic Motor | ||||||

| Abs Avg Error (mechanical degrees) | 3.6e-1 | 5.98 | 94.0 | 3.95e-1 | 4.54 | 91.5 |

| Max Error (mechanical degrees) | 3.85 | 95.8 | 96.0 | 4.03 | 53089 | 92.5 |

| Estun Motor | ||||||

| Abs Avg Error (mechanical degrees) | 3.32e-1 | 10.19 | 96.7 | 3.48e-1 | 51.05 | 99.3 |

| Max Error (mechanical degrees) | 2.12 | 126.75 | 98.3 | 1.76 | 113.55 | 98.4 |