SSZT609 october 2018 BQ25505 , CC1310 , CC2640R2F , TPL5111 , TPS2660

Oct 10, 2018

It takes a couple of weeks to completely re-price everything in a store by hand with new paper tags. Not only is this time-consuming, but it is costly and hard on the environment due to the enormous amount of required paper. Electronic shelf labels (ESLs) can eliminate the manpower needed to re-price items, reduce the use of paper, and conserve printing costs, in favor of better store profitability and a better customer experience.

ESLs connect shoppers at the shelf, offering more effective advertisements based on customer preferences and needs, helping with product selection by indicating the exact location of a specific product (like a printer cartridge), and facilitating the payment process by enabling customers to scan price tags and pay with a smartphone.

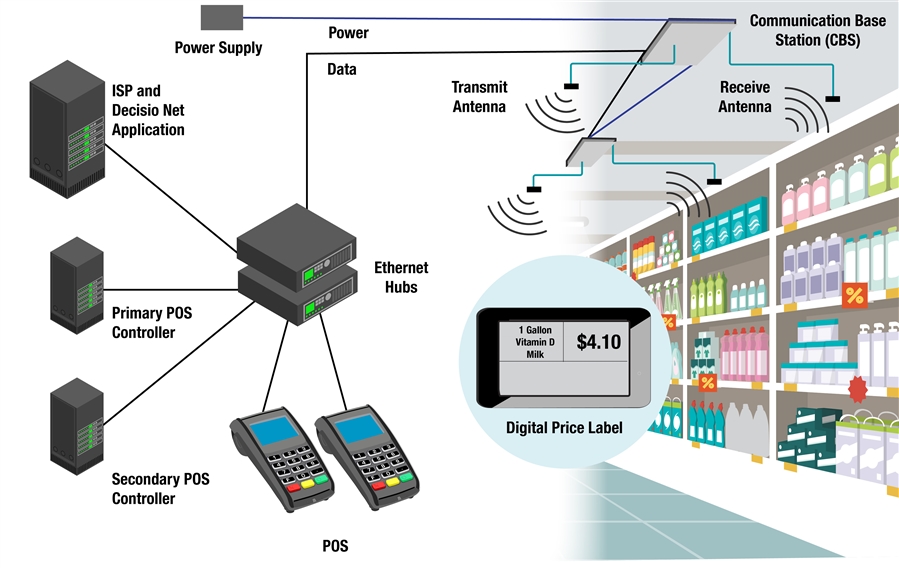

The system, as shown in Figure 1, essentially consists of a wireless dialogue among:

- ESLs displaying the price and universal product code (UPC) through an LCD/e-ink display on store shelves.

- Access points that create a network bridge between the central host and ESLs.

- A central host that transmits price updates through access points to the ESLs and the point of sale (POS).

- A POS where customers complete the payment process.

Figure 1 Store Architecture

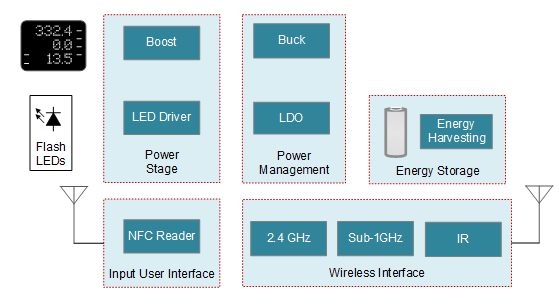

Figure 1 Store ArchitectureLooking at the architecture of an ESL as shown in Figure 2, the subsystem core is a wireless interface that connects to a central host through access points, eliminating any discrepancies between shelves and cash register prices. SimpleLink™ Arm®-based ultra-low-power wireless microcontrollers (MCUs) enable multiyear operations over a coin-cell battery and provide flexibility in the choice of wireless technology, usually 2.4GHz and Sub-1 GHz proprietary wireless protocols.

For example, the Humidity and Temp Sensor Node for Sub-1 GHz Star Networks Enabling 10+ Year Coin Cell Battery Life reference design uses the CC1310 MCU and TPL5111 nanopower system timer to control power to all remaining circuitry while consuming only tens of nanoamperes when operating. The CC2640R2F is an alternative option using the same software development kit (SDK) if a 2.4 GHz proprietary protocol is required by the system.

Figure 2 ESL Reference Diagram

Figure 2 ESL Reference DiagramWhile the upfront cost may be great, energy harvesting solutions can increase ESL battery life and will be more cost-effective over time. TI designed the BQ25505 ultra-low-power harvester power-management integrated circuit (IC) to efficiently extract the microwatts to milliwatts of power generated from a variety of DC energy harvesting and high-impedance sources. For example, the Indoor Light Energy Harvesting Reference Design for Bluetooth® Low Energy Beacon Subsystem uses just the power of typical indoor lighting in a retail environment (>250 lumens/m2) to transmit data wirelessly.

ESLs equipped with sensors (like humidity, temperature or weight sensors) and cameras can monitor the condition of fresh goods, streamline restocking activities, or track users and objects. Ultra-low-power, small and very accurate sensors are needed for this purpose. The accuracy is needed to understand which products have been picked from the shelf – especially when stores have thousands of products to choose from.

High-performance protection diodes protect the communication interfaces – because ESLs are susceptible to electrostatic discharge damage from people touching them. A low-power wireless MCU, efficient power management and a robust protection circuit are just a few of design elements required to build smart, green and agile ESLs, which will increase retailer profitability, improve the customer experience and make a greener world.

Additional Resources

- Learn more about ESL ICs and reference designs.

- Check out the Low-Power Wi-Fi® Enabled Electronic Paper Display (EPD) reference design.

- Build differentiated EPOS designs.