SBOA160D july 2016 – april 2023 INA240 , INA240-Q1 , INA253 , INA253-Q1 , INA254 , INA282 , INA282-Q1 , INA283 , INA283-Q1 , INA284 , INA284-Q1 , INA285 , INA285-Q1 , INA286 , INA286-Q1 , LMP8481 , LMP8481-Q1 , LMP8602 , LMP8602-Q1 , LMP8603 , LMP8603-Q1

The demand for higher efficiency systems continues to increase, leading to direct pressure for improvement in motor operating efficiency and control. This focus applies to nearly all classes of electric motors including those used in white goods, industrial drives and in automotive applications. The operational characteristics of the motor fed back into the control algorithm are critical to make sure the motor is operating at peak efficiency. Phase current is one of these critical diagnostic feedback elements used by the system controller enabling optimum motor performance.

Due to the continuity of the measurement signal and direct correlation to the phase currents, an ideal location to measure the motor current is directly in-line with each phase as shown in Figure 1. Measuring current in other locations, such as the low-side of each phase, requires recombination and processing before meaningful data can be utilized by the control algorithm.

Figure 1 In-Line Current Sensing

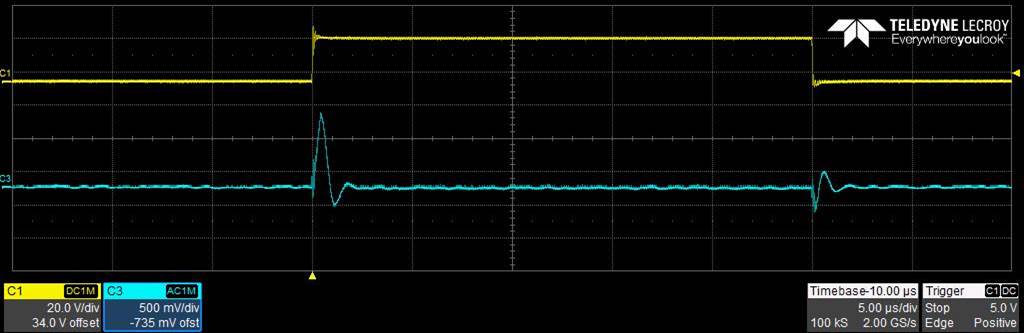

Figure 1 In-Line Current SensingThe drive circuitry for the motor generates pulse width modulated (PWM) signals to control the motor’s operation. These modulated signal subject the measurement circuitry placed in-line with each motor phase to common-mode voltage transitions that can switch between large voltage levels over very short time periods. An ideal amplifier has the ability to completely reject the common-mode voltage component of the measurement and only amplifier the differential voltage corresponding to the current flowing through the shunt resistor. Unfortunately, real-world amplifiers are not ideal and are influenced by the large PWM-driven input voltage steps. Because real-world amplifiers do not have infinite common-mode rejection potentially large, unwanted disturbances appear at the amplifier output corresponding to each input voltage step as shown in Figure 2. These output disturbances, or glitches, can be very large and take significant time to settle following the input transition depending on the characteristics of the amplifier.

Figure 2 Typical Output Glitch From Large Input

VCM Step

Figure 2 Typical Output Glitch From Large Input

VCM StepA common approach to this measurement is to select a current sense amplifier with a wide bandwidth. To stay above the audible frequency range, modulation frequencies ranging from 20 kHz to 30 kHz are typically selected. Amplifier selection for making in-line current measurements in these PWM-driven applications targets amplifiers with signal bandwidths in the 200-kHz to 500-kHz range. The selection of the amplifier was not historically based on actual signal bandwidth which are significantly lower than the PWM signal. The higher amplifier bandwidths were selected to allow the output glitch to settle quickly following an input voltage transition.

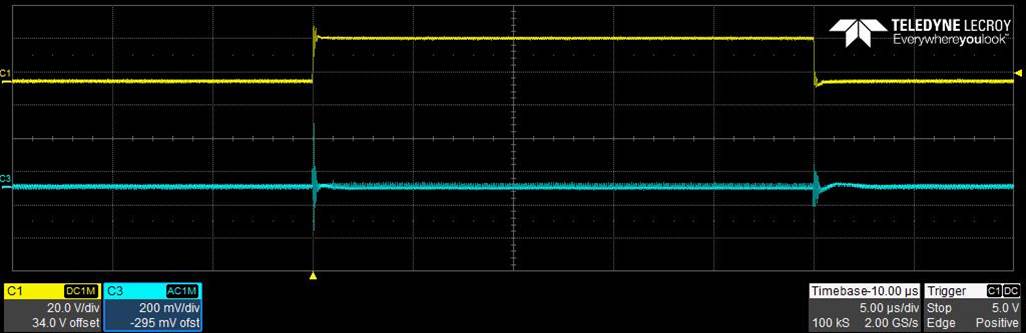

The INA240 is a high common-mode, bi-directional current sense amplifier designed specifically for these types of PWM-driven applications. This device approaches the problem of measuring a small differential voltage in the presence of large common-mode voltage steps using integrated enhanced PWM rejection circuitry to significantly reduce the output disturbance and settle quickly. Standard current sense amplifiers rely on a high signal bandwidth to allow the output to recover quickly following the step, while the INA240 features a fast current sense amplifier with internal PWM rejection circuitry to achieve an improved output response with reduced output disturbance. Figure 3 illustrates the improved response of the INA240 output due to this internal enhanced PWM rejection feature.

Figure 3 Reduced Output Glitch By Enhanced PWM

Rejection

Figure 3 Reduced Output Glitch By Enhanced PWM

RejectionFor many three-phase applications there are few requirements on the accuracy of this in-line current measurement. Limited output glitch is necessary to prevent false over-current indications in addition to having an output that quickly responds to provide sufficient control of the compensation loop. For other systems, such as electronic power steering (EPS), precise current measurements are needed to provide the required feedback control to the torque assist system. The primary objectives in an EPS system are to assist with additional torque to the driver’s applied torque on the steering wheel and provide a representative feel in the steering response corresponding to the driving conditions. Phase to phase current measurement errors can become very noticeable in this tightly controlled system. Any unaccounted for variance between phases leads directly to increased torque ripple that is perceptible to the driver through the steering wheel. Reducing the measurement errors, especially those induced by temperature, is critical to maintain the accurate feedback control and to deliver a seamless user experience.

Common system-level calibration frequently reduces the reliance of the performance on an amplifier at room temperature to provide precise measurement accuracy. However, accounting for parameter shifts such as input offset voltage and gain error as the operating temperature varies is more challenging. Good temperature compensation schemes are based on characterization of the amplifier’s performance variation over temperature and rely on consistent and repeatable response to external conditions from system to system. Improving the capability of the amplifier to remain stable with minimal temperature induced shifts is ideal to reduce the need for complex compensation methods.

The INA240 features a 25-µV maximum input offset voltage and a 0.20% maximum gain error specification at room temperature. More importantly for applications requiring temperature stable measurements, the input offset voltage drift of the device is 250 nV/°C with a 2.5 ppm/°C amplifier gain drift. Even as the operating temperature varies over the system’s entire temperature range, the measurement accuracy remains consistent.

The INA253 and INA254 features all of the performance benefits of INA240 amplifier with the inclusion of integrated shunt. The integrated shunt is a low inductive, precision, 2 mΩ with 0.1% tolerance (INA253) or 400 µΩ with 0.5% tolerance (INA254) both have temperature drift of < 15 ppm/°C. The INA253 is the most accurate current sense amplifier that eliminates the error introduced due to shunt and parasitic introduced due to the layout.

Combining the measurement temperature stability, wide dynamic input range, and most importantly enhanced PWM input rejection, the INA240 is an appropriate choice for PWM-driven applications requiring accurate and reliable measurements for precisely controlled performance.

Alternate Device Recommendations

Depending on the necessary system requirements, there can be additional devices that provide the needed performance and functionality. The INA282 is able to very precisely measure large common-mode voltages that do not change as quickly as what is typically seen in PWM driven applications making the device appropriate for high-voltage DC applications. The INA241B is a bidirectional current sense amplifier used for high common-mode voltages that has PWM rejection technology.

| Device | Optimized Parameter | Performance Trade-Off |

|---|---|---|

| INA282 | Common-Mode Input Range: –14 V to +80 V; MSOP-8 Package | Low bandwidth, appropriate for DC applications |

| INA241B | –5-V to 110-V bidirectional high-precision current sense amplifier with enhanced PWM rejection | Increased IQ |