SLUAAJ7 June 2022 UCC256402 , UCC256403 , UCC256404

- Abstract

- Trademarks

- 1UCC25640x Selection Guide

- 2UCC25640x Features Brief Overview

- 3UCC25640x Power Up Guidelines and Debugging Notes

- 4References

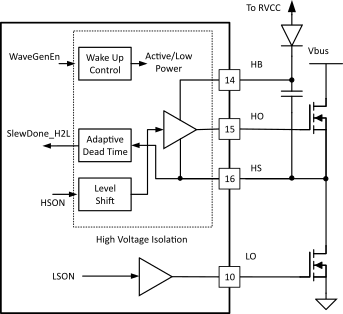

2.7 Adaptive Dead Time Control

Figure 2-32 Adaptive Dead Time

Control

Figure 2-32 Adaptive Dead Time

Control- LO turns on when HS detects a slew rate change from high to low (During a switching transition, the slew rate rises up first and then drops back to zero) – indicating HS voltage reaches the minimal value. So, the dead time from HO to LO is automatically adjusted based on HS voltage.

- Minimal detectable slew rate is 0.1 V/ns (check when HS at 20 V).

- Dead time from LO to HO is copied from the previous HO to LO switching.