SLVAFI8 February 2023 TLC6C5748-Q1

- Abstract

- Trademarks

- 1Introduction

-

2Design Considerations for Low EMI

- 2.1 Design Considerations Overview

- 2.2

Considerations in Detail

- 2.2.1 Top-Level Architecture

- 2.2.2

High Frequency Signals

- 2.2.2.1 Original Setup

- 2.2.2.2 3.3 V I/O Voltage Instead of 5 V

- 2.2.2.3 Use Independent OSC for GSCLK With Spread Spectrum

- 2.2.2.4 Without Using Buffer on GSCLK

- 2.2.2.5 Using Snubber on GSCLK

- 2.2.2.6 Lower the Signal Frequency

- 2.2.2.7 Placement and PCB layout

- 2.2.2.8 ESD Enhancement

- 2.2.2.9 Demo and Test Results

- 2.2.2.10 Bench Test Results

- 3Summary

- 4References

2.2.2.6 Lower the Signal Frequency

In particular with TLC6C5748-Q1, the data throughput of the local dimming SPI interface (SIN, SCLK) is calculated in #GUID-B96E3F9C-6983-41C4-97F8-B5D9FC368E12. For example, a 336-zone design with 60 Hz frame rate requires about 0.32 MHz SCLK/SIN. TLC6C5748-Q1 only updates the brightness when the LAT pulse arrives, thus the whole frame period could be used for brightness data transfer.

Besides, GSCLK is an independent clock for PWM dimming counter. In some applications, high PWM (for example, >20 kHz) dimming frequency is needed to avoid audible noise and moiré pattern. On TLC6C5748-Q1, the control bit of ESPWM is recommended to be set when high PWM dimming frequency is required. With ESPWM enabled, the relationship between PWM dimming frequency and GSCLK is given as shown in #GUID-F508AAA9-4A2B-41EC-B84E-2A07DDC4AF11.

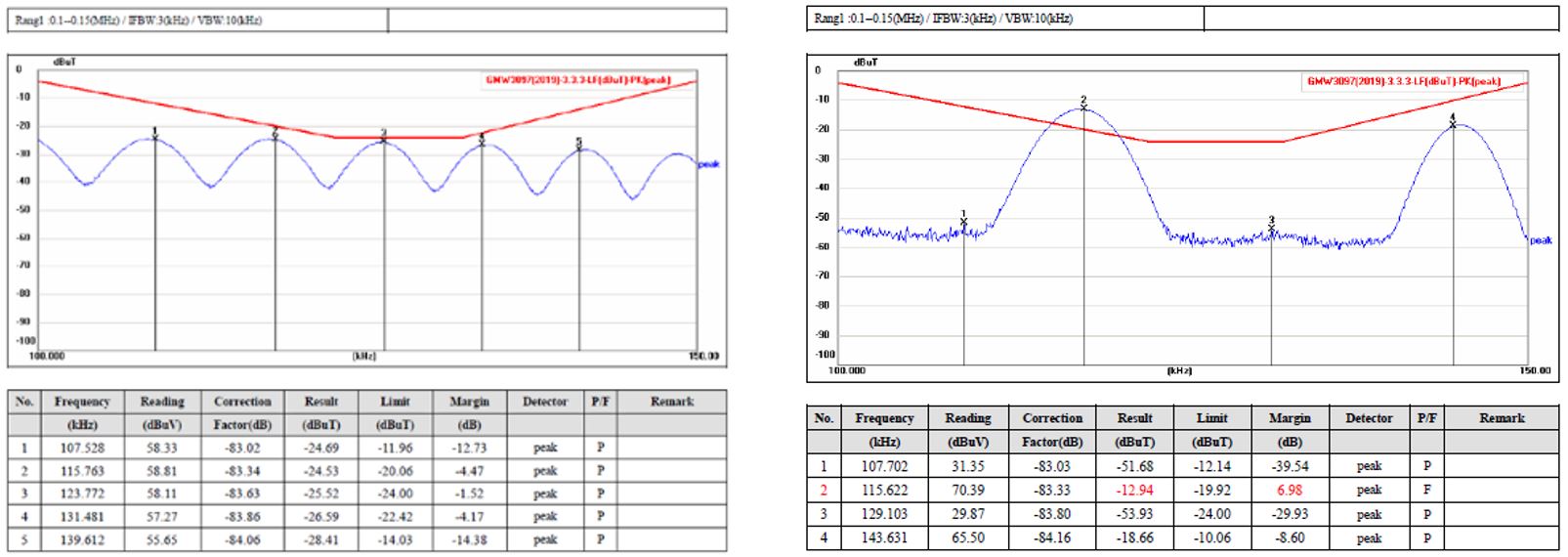

For example, to achieve a PWM dimming frequency over 20 kHz, it requires 10.24 MHz GSCLK frequency in minimum. Some OEMs may have limitations for near-field magnetic field emission in specific low frequency band. In most cases, such kind of low frequency magnetic radiated emission directly sourced from the current loop during PWM dimming operation. The radiated spikes on the frequency spectrum is directly related to the GSCLK frequency because the PWM dimming frequency is divided from GSCLK. Thus, it’s also important to select the GSCLK frequency carefully to avoid the spikes locates at the sensitive band. For audible noise, in addition to boost the PWM dimming frequency, we can use Tantalum - Polymer capacitors. Compared with MLCC (Mount Multilayer Ceramic Capacitors), the Tantalum - Polymer capacitors will not have vibration noise. And the common method to pass the near-field magnetic field emission is lowering down the GSCLK. For example, GMW3097 specification has limitation of near-field magnetic field emission in 100 kHz to 150 kHz. According to #GUID-F508AAA9-4A2B-41EC-B84E-2A07DDC4AF11, PWM dimming frequency is 7.8 kHz and 48.8 kHz when GSCLK is 4 MHz and 14.3 MHz. Lower frequency of the signals, the lower amplitude in the high frequency range as shown in #FIG_O3P_PNL_FWB.

Figure 2-8 Near Field Test Results of

Original Setup from 100kHz to 150kHz

Figure 2-8 Near Field Test Results of

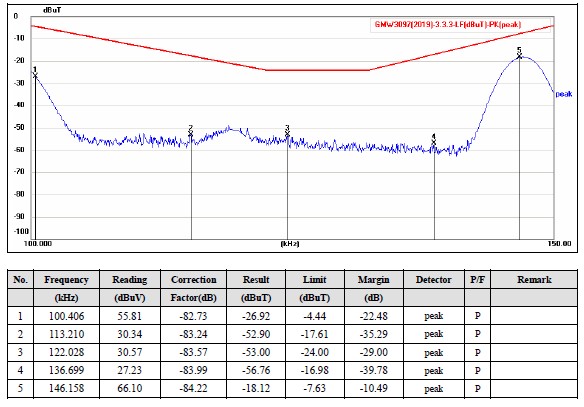

Original Setup from 100kHz to 150kHzAccording to #GUID-F508AAA9-4A2B-41EC-B84E-2A07DDC4AF11, to design an appropriate LED dimming frequency is also a good way to pass the specification. For example, 50 kHz LED dimming frequency is appropriate because it has EMI noise peak on 50 kHz, 100 kHz, 150 kHz and so on which means that it can avoid the tight limitation on 100 kHz to 150 kHz. #FIG_FPC_H4L_FWB shows the near field test result when GSCLK is 25 MHz and turn on the ESPWM. In addition, spread the regulated capacitors over the LED board can also reduce the EMI noise from LED dimming frequency.

Figure 2-9 Near Field Test Results of

Optimized Setup from 100kHz to 150kHz

Figure 2-9 Near Field Test Results of

Optimized Setup from 100kHz to 150kHz