SLVUBO3A April 2019 – October 2020 TPS650330-Q1

- Trademarks

- 1BOOSTXL-TPS65033 Components and Environment

- 2BOOSTXL-TPS65033 Board Information

- 3Programming GUI Operation

- 4Recommended Operating Procedure

- 5BOOSTXL-TPS65033 Schematic

- 6BOOSTXL-TPS65033 Board Layers

- 7BOOSTXL-TPS65033 Bill of Materials

- 8Revision History

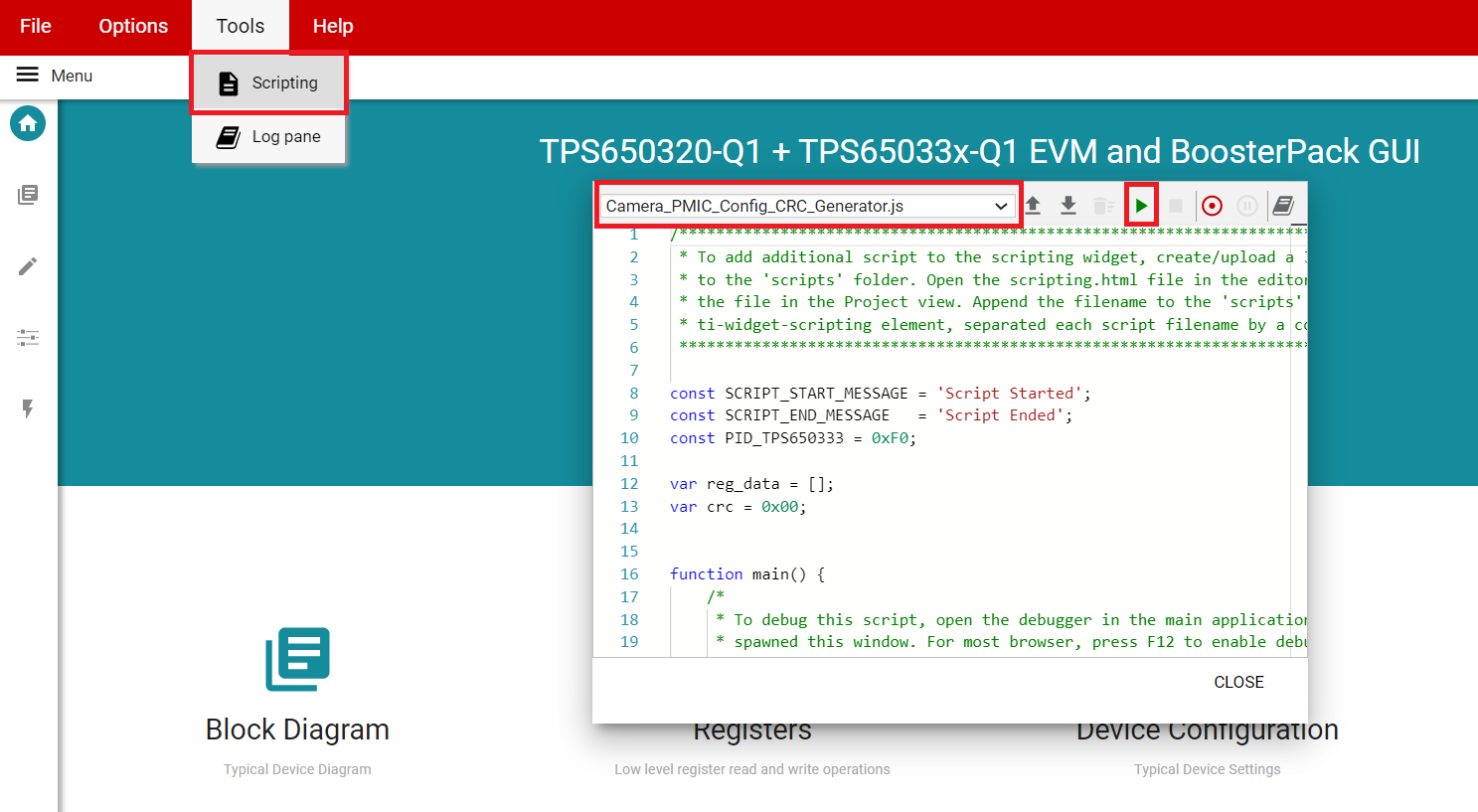

3.4 Scripting

The GUI includes a scripting feature in the tools menu at the top of the window. Scripting enables automated writes and reads to the PMIC, allowing sequential instructions to be sent to the PMIC. Scripts can be saved as a .js or .txt file, and imported using the Upload arrow at the top of the scripting window. Scripting allows the re-configuration of multiple PMICs before sending to assembly or populating on a PCB.

Figure 3-21 TPS6503xx-Q1 GUI Scripting

Window

Figure 3-21 TPS6503xx-Q1 GUI Scripting

WindowAn example script for re-programming a device can be seen below, where output voltages and sequencing settings are reconfigured from the default settings.

/* Entry point for the script, which will be executed when the user presses the PLAY button in the Scripting Dialog. */

function main() {

write('CONTROL_LOCK', 0xDD); // Unlock control registers

write('CONFIG_LOCK', 0xAA); // Unlock configuration registers

write('GPIO_CTRL',2); // Disable configuration CRC

write('BUCK_LDO_CTRL',0x00); // Turn off all regulators to prevent faults

write('BUCK3_VOUT',6); // Change Buck 3 output voltage

write('LDO_VOUT',8); // Change LDO output voltage

write('SEQ_TRIG_BUCK2',10); // Update Buck 2 sequence dependencies

write('SEQ_TRIG_BUCK3',2); // Update Buck 3 sequence dependencies

write('SEQ_TRIG_LDO',26); // Update LDO sequence dependencies

write('SEQ_TRIG_nRSTOUT',2); // Update nRSTOUT sequence dependencies

write('BUCK1_SEQ_DLY',145); // Update Buck 1 sequence delay

write('BUCK2_SEQ_DLY',86); // Update Buck 2 sequence delay

write('BUCK3_SEQ_DLY',54); // Update Buck 3 sequence delay

write('LDO_SEQ_DLY',118); // Update LDO sequence delay

write('nRSTOUT_SEQ_DLY',6); // Update nRSTOUT sequence delay

write('BUCK_LDO_CTRL',31); // Re-enable all regulators

write('EEPROM_PROG_CMD',45); // Burn settings into EEPROM

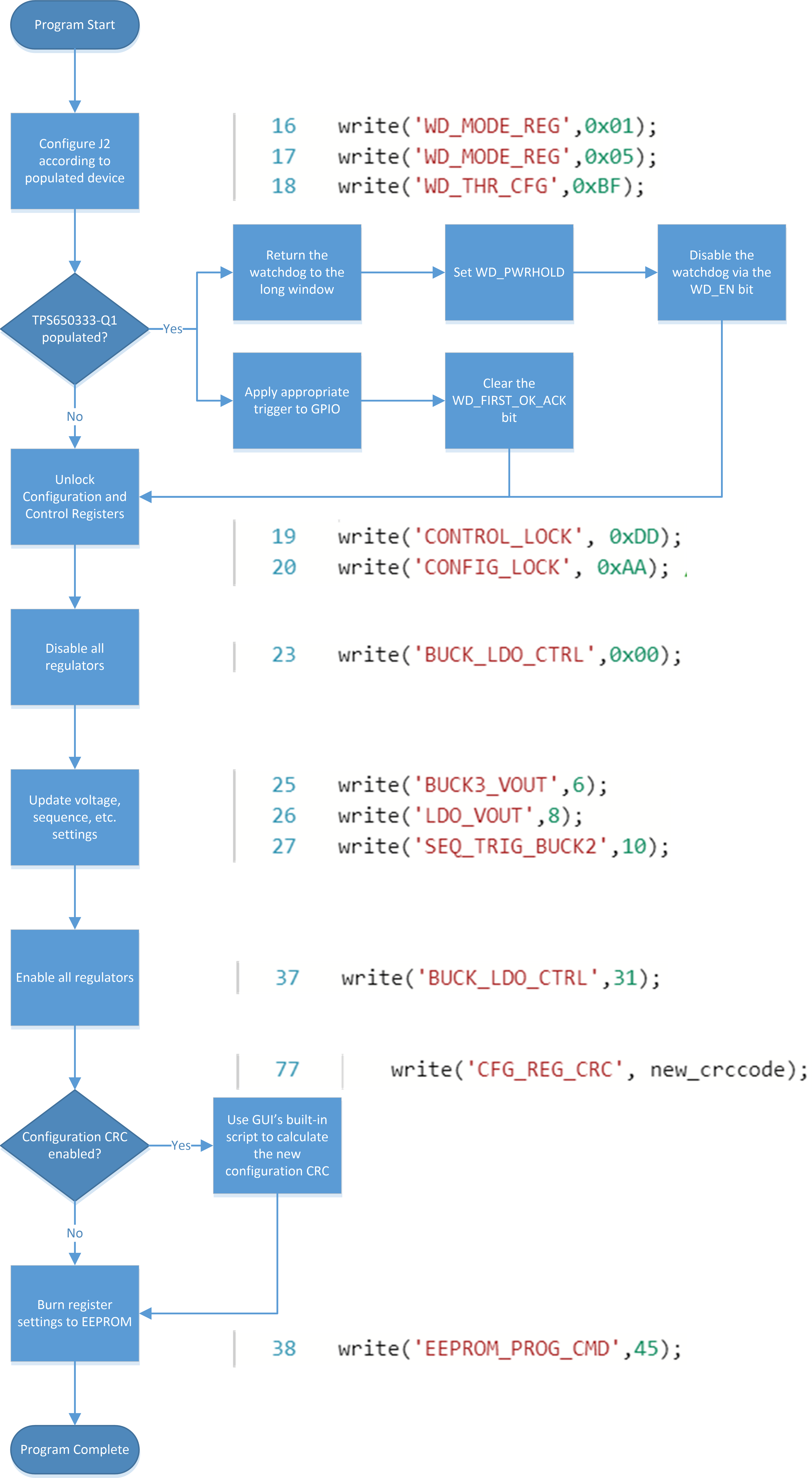

}Figure 3-22 details the typical device programming flow. Most blocks can be executed with one or more register write commands in the script file. Only the J2 configuration and GPIO trigger application cannot be done via scripting.

Figure 3-22 Example Script Program

Flow

Figure 3-22 Example Script Program

Flow