SNLA364C March 2021 – June 2022 DP83TD510E

- Abstract

- Trademarks

- 1 Introduction

- 2 1-V and 2.4-V p2p Mode Scripts

- 3 Time-Domain Reflectometry

- 4 Active Link Cable Diagnostics

- 5 Signal Quality Indicator

- 6 Cable Diagnostics Summary

- 7 Loopback Modes

- 8 Pseudo-Random Bit Sequence Functions

- 9 USB to MDIO Procedure

- 10IEEE 802.3cg PMA Compliance

- 11Revision History

4.2.1 Cable Calibration

The ALCD will need to be calibrated to each cable type and application by measuring the ALCD register information at five regular intervals up to the maximum cable reach the application requires. The calibration can be done in a designer's lab during product evaluation. A good cable will not deviate much in its characteristics from the test cable used in calibration to those deployed in the field, allowing calibration to be performed once for a PHY-cable pair. To perform the calibration and estimate the cable reach of a link, follow the following procedure.

- The maximum cable length expected to be used in the field with DP83TD510E Ethernet PHY is referred to as maximum operating length with the Ethernet PHY. For example, if 900 m is expected to be the longest cable length which will be used in the field, then 900 m is called as the maximum operating length. ALCD will have reference data for the maximum operating length with some margin for degradation in the cable performance over time. The margin can be fixed (say 10%) or can be derived from the performance with the higher cable length. For the example we can assume a 10% margin and generate reference data for approximately 1 km. It will be referred to as ALCD range.

- The ALCD calibration is done in five segments of

ALCD cable range. It is recommended that these segments are equal or nearly equal in

length. For example, we can use either of the following cable lengths for calibrating

ALCD or any other set close to these values for ALCD range of 900m. Do keep in mind

that the longest cable length for calibration needs to be greater than actual used

cable.

Set 1: {0m, 200m, 400m, 600m, 800m, 1km}

- An ALCD metric is calculated by the PHY for each

segment of the ALCD cable range. It is internally generated by the silicon and is

displayed in register 0x0A9D after the link up is achieved. Follow the procedure

below to read the correct value of the ALCD metric at each segment length.

- Program with a desired script if necessary, and let the devices link up.

- Wait for 3ms after the link up is achieved and read register 0x0A9D for the ALCD metric.

- Ignore the LSB hexadecimal digit, and store the 3 MSB hexadecimal digits of the metric.

- Repeat steps a. through c. for all cable lengths in the calibration set to obtain a calibration pair for 1 V mode and 2.4 V mode.

- Once the ALCD reference metric is recorded for each cable length, these values can be stored in the DP83TD510E registers to estimate the length of the cable over the lifetime of the application. Six pairs of <cable, metric> are required to be generated following the procedure described above. This information needs to be stored in registers as per Table 4-1 and needs to be part of initial link up script.

| Parameter | Register Address | Comments |

|---|---|---|

| 2p4V Metric1 | 0x088D | 3 MSB hexadecimal digits for metric 1 for 2p4V mode |

| 2p4V Metric2 | 0x088E | 3 MSB hexadecimal digits for metric 2 for 2p4V mode |

| 2p4V Metric3 | 0x088F | 3 MSB hexadecimal digits for metric 3 for 2p4V mode |

| 2p4V Metric4 | 0x0890 | 3 MSB hexadecimal digits for metric 4 for 2p4V mode |

| 2p4V Metric5 | 0x0891 | 3 MSB hexadecimal digits for metric 5 for 2p4V mode |

| 2p4V Metric6 | 0x0892 | 3 MSB hexadecimal digits for metric 6 for 2p4V mode |

| 1V Metric1 | 0x0898 | 3 MSB hexadecimal digits for metric 1 for 1p0V mode |

| 1V Metric2 | 0x0899 | 3 MSB hexadecimal digits for metric 2 for 1p0V mode |

| 1V Metric3 | 0x089a | 3 MSB hexadecimal digits for metric 3 for 1p0V mode |

| 1V Metric4 | 0x089b | 3 MSB hexadecimal digits for metric 4 for 1p0V mode |

| 1V Metric5 | 0x089c | 3 MSB hexadecimal digits for metric 5 for 1p0V mode |

| 1V Metric6 | 0x089d | 3 MSB hexadecimal digits for metric 6 for 1p0V mode |

| Cable1 | 0x08E9 | Round(Cable1/8) and convert it to hexadecimal digits |

| Cable2 | 0x08EA | Round(Cable2/8) and convert it to hexadecimal digits |

| Cable3 | 0x08EB | Round(Cable3/8) and convert it to hexadecimal digits |

| Cable4 | 0x08EC | Round(Cable4/8) and convert it to hexadecimal digits |

| Cable5 | 0x08ED | Round(Cable5/8) and convert it to hexadecimal digits |

| Cable6 | 0x08EE | Round(Cable6/8) and convert it to hexadecimal digits |

Register information is not retained over power cycles. ALCD calibration information should be included in an initialization routine to be available for cable length estimation after each power-up.

The longest cable length for calibration must be greater than actual cable used .

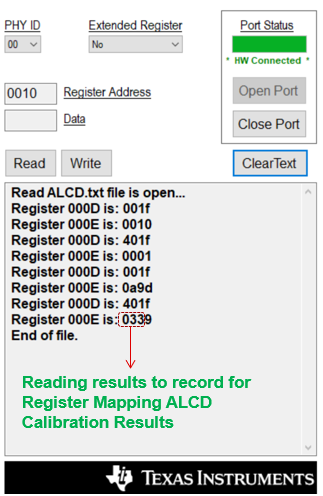

Figure 4-1 Example Reading For

Calibration

Figure 4-1 Example Reading For

CalibrationProcedure to generate ALCD metric:

//For each output operating mode utilized in an application, record ALCD <cable, metric pair>

1.0 Vpp operating ALCD metrics

//For each cable length segment in ALCD range, record the ALCD metric

begin

0001 //check that link is established in 0x0001[2]

0A9D //read register 0x0A9D and record bits [15:4] for

end

2.4 Vpp operating ALCD metrics

//For each cable length segment in ALCD range, record the ALCD metric

begin

0001 //check that link is established in 0x0001[2]

0A9D //read register 0x0A9D and record bits [15:4] for

endSet ALCD calibration registers during initialization routine:

begin

//Set ALCD cable length segments

08E9 0000 //Cable length 1 is 0 meters

08EA 0019 //Cable length 2 is 200 meters ([200 meters / 8] -> converted to hex)

08EB 0032 //Cable length 3 is 400 meters ([400 meters / 8] -> converted to hex)

08EC 004B //Cable length 4 is 600 meters ([600 meters / 8] -> converted to hex)

08ED 0064 //Cable length 5 is 800 meters ([800 meters / 8] -> converted to hex)

08EE 007D //Cable length 6 is 1000 meters([1000 meters / 8] -> converted to hex)

//Set 1.0 Vpp ALCD metrics

0898 0046 //ALCD metric for 0 meters is 046

0899 0067 //ALCD metric for 200 meters is 067

089A 0088 //ALCD metric for 400 meters is 088

089B 0137 //ALCD metric for 600 meters is 137

089C 0178 //ALCD metric for 800 meters is 178

089D 0263 //ALCD metric for 1000 meters is 263

//Set 2.4 Vpp ALCD metrics

088D 0078 //ALCD metric for 0 meters is 078

088E 0096 //ALCD metric for 200 meters is 096

088F 0120 //ALCD metric for 400 meters is 120

0890 0174 //ALCD metric for 600 meters is 174

0891 0201 //ALCD metric for 800 meters is 201

0892 0310 //ALCD metric for 1000 meters is 310

end