SSZT268 july 2020 SN74AXC1T45 , SN74AXC2T245 , SN74AXC2T45

Internet of Things (IoT) and industrial Internet of Things (IIoT) have become synonymous with connected factories and making traditional factories smarter in order to reap the benefits of greater efficiency. Today, it’s becoming more common for factory equipment to monitor and control collocated equipment such as chemical storage tanks, pumping equipment, leak detection equipment, or fire monitoring equipment. The next phase of IIoT involves factory connections that expand beyond the confines of the factory walls.

For factory assets located outside the traditional factory floor, wireless battery-powered sensing and control are becoming essential for integrating these assets into the factory control infrastructure economically and efficiently. Why are battery-powered sensing and control relevant when extending the factory beyond its original footprint? The simple answer is that factories often evolve over time, sometimes decades, and battery-powered sensing and control enable the unfettered placement of sensing and control nodes at locations likely never imagined in the original factory design. Battery-powered sensing and control nodes also do not need dedicated power and communication lines, which are usually very difficult and expensive to extend beyond the original factory floor infrastructure.

In order for battery-powered sensing and control to be practical for integration into a factory environment, sensing and control nodes must be able to operate reliably over an extended period of time without needing to replace or recharge the battery. Battery-powered sensing and control implementations often have elements such as sensors, low-voltage processors and wireless communications modules at their core, which all need to operate in an extremely power-efficient manner.

The selection of these core components often requires selecting devices that may not be easily interoperable. For example, differing input/output (I/O) voltage levels are common among low-voltage devices and their different operating modes. A low-power sensor I/O may operate at 1.8 V when active, but the I/O can drop to below 1 V during deep-sleep mode to conserve battery life. Similarly, processor and communications module I/O voltage levels may operate at 2.5 V during active operation and then drop to a much lower voltage in low-power modes.

How can you bring together the core components of remote sensing and control designs and still take advantage of their low-power capabilities? The simple answer is to use low-power level-shifter devices like TI’s AXC level-shifter family that not only support low-power operation but also support shifting I/O levels down to 0.65 V (from 3.3 V to 0.65 V). AXC level-translator devices enable you to implement low-power level-shifting between core components for interfaces such as Serial Peripheral Interface, Universal Asynchronous Receiver Transmitter, general-purpose I/O and virtually any other push-pull interface, as well as the low-voltage I/O levels associated with the ultra-low-power modes of these devices. The AXC family’s ability to support voltage levels down to 0.65 V enables wireless battery-powered sensing and control applications to enter battery-saving modes that can limit I/O levels to less than 1 V.

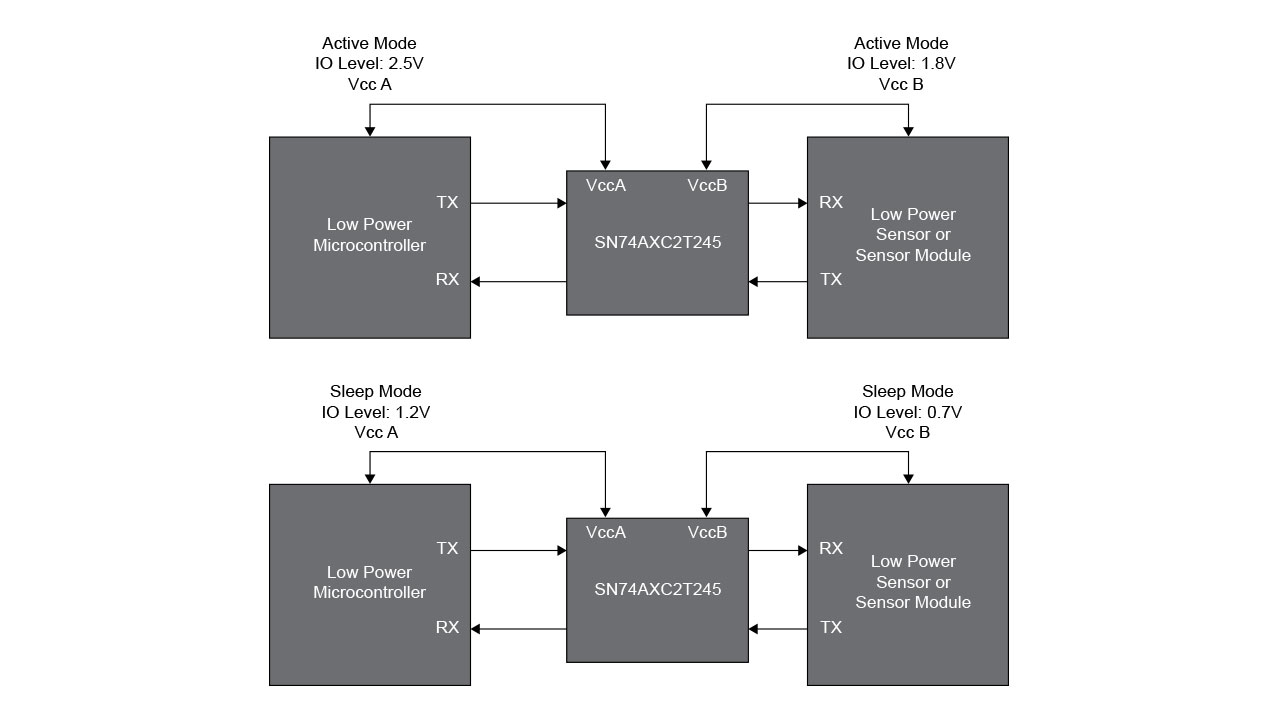

AXC devices are available in bit counts from one to eight bits, with lower-bit-count single- (SN74AXC1T45) and dual-channel (SN74AXC2T45, SN74AXC2T245) devices available in very small micro quad flat no-lead packages that are conducive to board-space-limited designs common in IIoT remote sensing and control. Figure 1 shows an example for a microcontroller and sensor link in active and sleep modes, and the example I/O levels for each operating mode.

Figure 1 Microcontroller-to-sensor link

in active and sleep modes

Figure 1 Microcontroller-to-sensor link

in active and sleep modesThe type of link shown in Figure 1 is implemented in many industrial sensing applications, such as communication module systems used in factory automation. A device like the SN74AXC2T245 can enable a sensor and microcontroller to operate efficiently in active mode while optimizing power efficiency in sleep or low-power mode. The SN74AXC2T245’s own power draw is also very low in both active and quiescent modes.

The AXC family of level shifters enables low-voltage and low-power IIoT remote sensing and control nodes that can extend factory floors beyond their original footprints.

For more information about TI’s AXC level-shifter family, see the TI voltage level translators page.