TIDUES6 August 2020 – MONTH

- Description

- Resources

- Features

- Applications

- 5

- 1System Description

- 2System Overview

- 3Hardware, Software, Testing Requirements, and Test Results

- 4Design Files

- 5Software Files

- 6Related Documentation

- 7Terminology

3.2.2.3 Thermal Performance

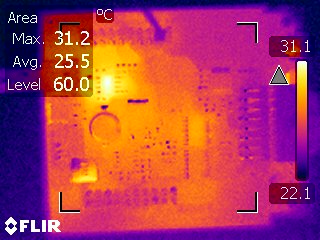

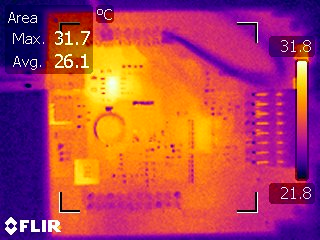

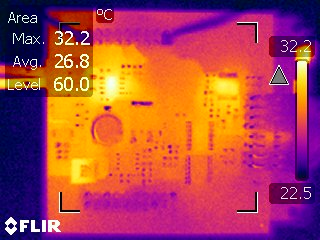

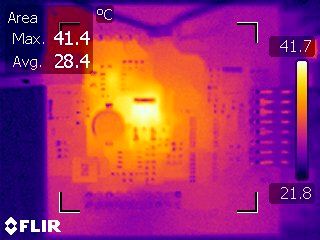

Thermal images of the TIDA-020027 board were taken under various operations to test the thermal performance of the board. The operations tested include operating the mirror folding motor, mirror heater, and the electrochromic mirror. The thermal images display the average and maximum temperature of the board.

Figure 3-8 shows the reference thermal image of the board connected to a power supply of 12.5 V with no loads being driven. The average temperature of the PCB is 25.5°C and the max temperature is 31.2°C.

Figure 3-9 is the thermal image while driving the mirror heater. The heater was driven to about a minute before taking the thermal image to allow the heater to reach its peak temperature. The average temperature of the PCB is 26.8°C and the maximum is 32.2°C.

Figure 3-10 shows the thermal image while driving the fold motor. The thermal image was taken while the fold motor was driven from one end to the other continuously. The max temperature of the board was measured at 31.7°C and the average temperature at 26.1°C.

Figure 3-11 is the thermal image of the PCB while driving the EC. The thermal image was taken once the mirror reached the programmed dimness level. The maximum temperature of the PCB was measured at 41.7°C which is concentrated around the Darlington BJT. The overall average temperature of the board is 28.4°C.

Figure 3-8 Reference Thermal Image of

PCB

Figure 3-8 Reference Thermal Image of

PCB Figure 3-10 Thermal Image of PCB While

Driving the Fold Motor

Figure 3-10 Thermal Image of PCB While

Driving the Fold Motor Figure 3-9 Thermal Image of PCB While

Driving the Mirror Heater

Figure 3-9 Thermal Image of PCB While

Driving the Mirror Heater Figure 3-11 Thermal Image of PCB While

Driving the Electrochromic Mirror

Figure 3-11 Thermal Image of PCB While

Driving the Electrochromic Mirror