SLVAE68B January 2021 – September 2022 DRV8242-Q1 , DRV8256 , DRV8424 , DRV8424E , DRV8425 , DRV8425E , DRV8426 , DRV8426E , DRV8428 , DRV8428E , DRV8434 , DRV8434E , DRV8436 , DRV8436E , DRV8850 , DRV8871 , DRV8871-Q1 , DRV8873 , DRV8873-Q1 , DRV8874 , DRV8874-Q1 , DRV8876 , DRV8876-Q1 , DRV8884 , DRV8885 , DRV8886 , DRV8886AT , DRV8889-Q1 , DRV8899-Q1 , DRV8935 , DRV8955 , LMD18245

Advantages of Integrated Current Sensing

Monitoring and regulating current is a must for many brushed and stepper motor applications. For brushed motors, the current information can be used to determine changes in load conditions or for limiting startup and stall currents. For stepper motors, high levels of micro-stepping require current to be regulated for each step.

In Figure 1-1, current is plotted versus time depicting the startup profile for a brushed DC motor. In this case, current is limited to approximately 2 amperes before the motor reaches a steady state condition of less than 1 ampere. Without current regulation, this same motor peaks to over 14 amperes. This not only requires an over-designed power supply to support this transient, but the motor driver also needs to be rated to reliably handle the peak currents.

Figure 1-1 DC Motor Current vs. Time

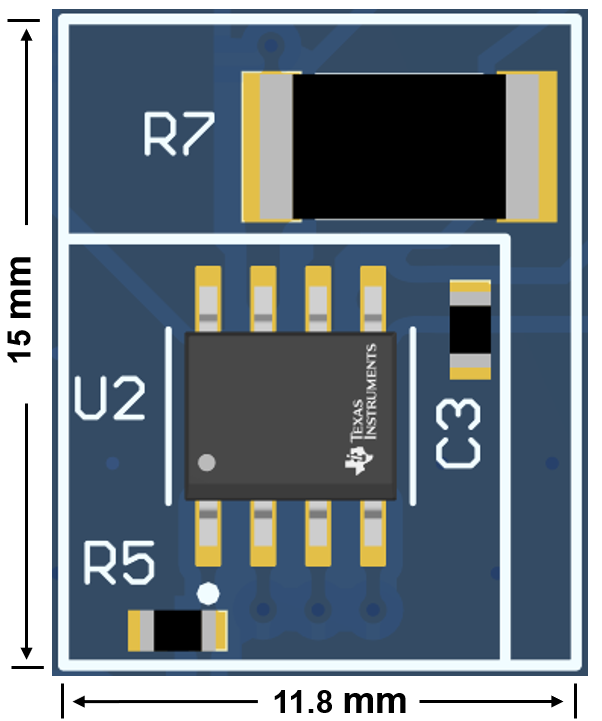

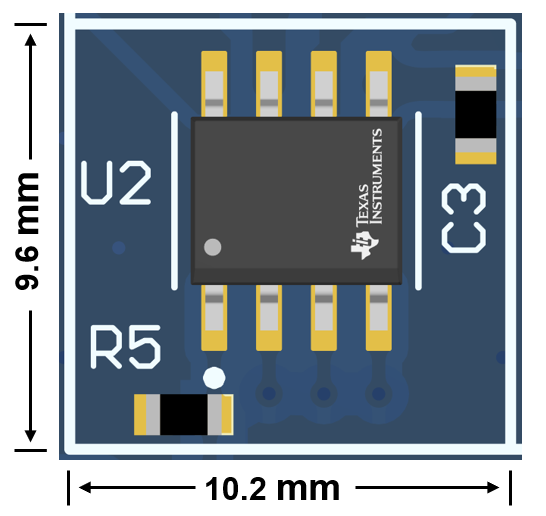

Figure 1-1 DC Motor Current vs. TimeTraditionally, this current limiting was achieved using external shunt resistors in the ground path. The voltage drop across these shunts was monitored and compared to a reference voltage either provided internally or externally depending on the device. Since the full load current passes through these shunts, the resistors must be power resistors and can be up to 2512 in case size which can be almost as large as the integrated circuit itself. Figure 1-2 shows the layout of the DRV8251 using external 2512 shunt resistor. Figure 1-3 shows the layout area for the DRV8251A and required passive components. The DRV8251A is capable of internal current regulation and removing the sense resistor decreases the PCB layout area. It is clear comparing Figure 1-2 and Figure 1-3 that integrated current sense leads to board and component savings as well as overall reduction in PCB area. A low wattage signal path resistor compared to a power resistor requires much smaller board space and lowers the bill of materials (BOM). Comparing the PCB area of the DRV8251A with the DRV8251, the DRV8251A PCB area is 55% smaller than the DRV8251. In addition to these benefits, there is no power loss across the resistor and one more heat source is eliminated from a design that is most likely already under thermal budget pressure.

Figure 1-2 DRV8251 With External Shunt

Figure 1-2 DRV8251 With External Shunt Figure 1-3 DRV8251A With Integrated Current

Sensing

Figure 1-3 DRV8251A With Integrated Current

SensingNow that current limiting and integrated current sensing benefits are well understood, you can also add monitoring capability in the newest family of brushed DC motor drivers through the IPROPI pin. The DRV8251A and DRV8231A are the newest product in the Brushed Motor Driver family that provides an analog current output proportional to the current flowing through the bridge. By passing this proportional current through a small resistor, a voltage proportional to current can be monitored with an external microcontroller to determine changes in load conditions and act accordingly. This internal current monitoring feature eliminates the need for an external power resistor and conditioning circuits like an operational amplifier. This E2E forum FAQ explains how IPROPI works and how to properly configure it for current sensing.

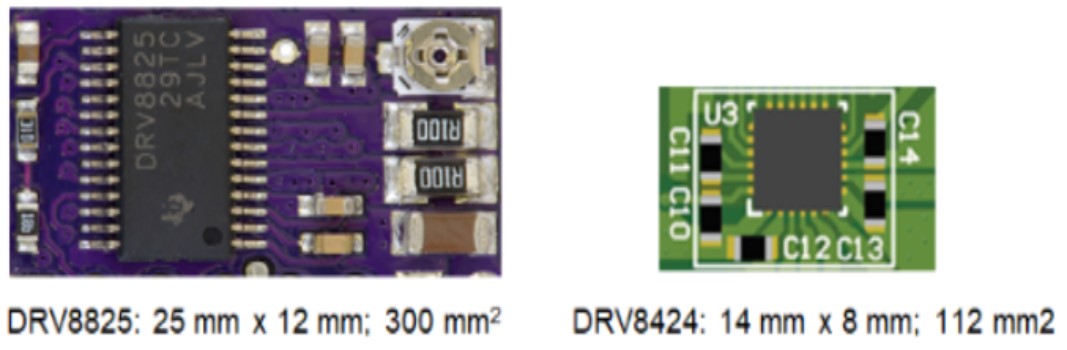

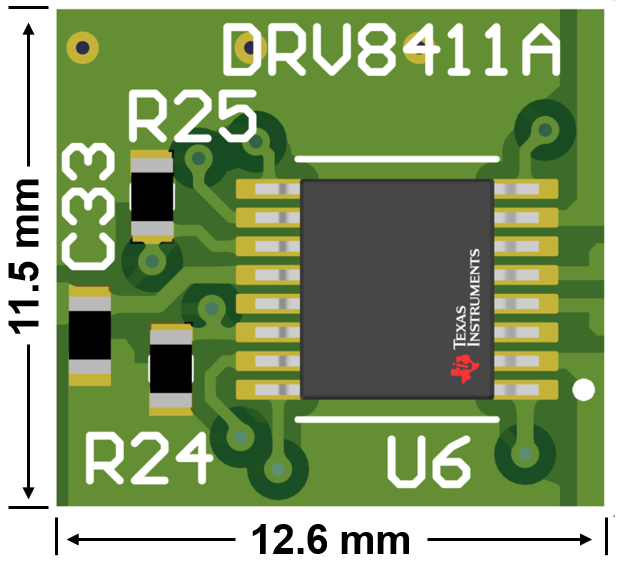

Finally, there are stepper motors that further benefit from the PCB size and BOM advantages of integrated current sensing since stepper motors have traditionally required two external sense resistors to feedback the current to the driver. Figure 1-4 compares the PCB footprint of a traditional driver like the DRV8825 to DRV8424 or the newest driverDRV8411A. The board with DRV8424 is 60% smaller than the board with DRV8825 and DRV8411A is 50% smaller.

Figure 1-4 Board Layout Reduction

Figure 1-4 Board Layout ReductionOne less tangible benefit that is only realized during PCB layout is the simplicity of the layout when choosing a device with the integrated sensing feature. It is no longer necessary to route around the large external shunt components and break up power, output, and GND routing that require larger traces for carrying device current.

In summary, integrated current sensing in TI's latest family of motor drivers removes costly power resistors from the BOM, reduces board size, component count, and simplifies PCB routing.

| Device Name | Device Description |

|---|---|

| DRV8411A | 11 V, 4A Stepper Motor driver with integrated current sensing |

| DRV8424 | 35 V, 2.5A Stepper Motor driver with integrated current sensing |

| DRV8426 | 35 V, 1.5A Stepper Motor driver with integrated current sensing |

| DRV8428 | 35 V, 1A Stepper Motor driver with integrated current sensing |

| DRV8436 | 50 V, 1.5A Stepper Motor driver with integrated current sensing |

| DRV8452 | 48 V, 4A Stepper Motor driver with integrated current sensing |

| DRV8462 | 60 V, 5A Stepper Motor driver with integrated current sensing |

| DRV8873 | 37 V, 10A Brushed DC Motor driver with integrated current sensing |

| DRV8874 | 37 V, 6A Brushed DC Motor driver with integrated current sensing |

| DRV8876 | 37 V, 3.5A Brushed DC Motor driver with integrated current sensing |

| DRV8251A | 50 V, 4.1A Brushed DC Motor driver with integrated current sensing |

| DRV8231A | 35 V, 3.7A Brushed DC Motor driver with integrated current sensing |