SSZTA23 July 2017 DRV5013-Q1 , DRV8305-Q1 , DRV8702-Q1 , DRV8703-Q1 , DRV8703D-Q1

With the advent of smaller and smarter integrated circuits (ICs) in automotive electrical systems, it’s time to start addressing the elephant in the room: Why are we still controlling motors in sunroof modules, window lifts, power locks, tailgate lifts, memory seats, compressors and pumps with relays? Sure, relays are cheap and simple to design with, but their functionality is limited to the point that they now seem cumbersome for modern motor applications given their limited lifetime and large solution size. For a quiet, small and safe solution, a solid-state IC is the best option for automotive motor-control applications.

Solution Size

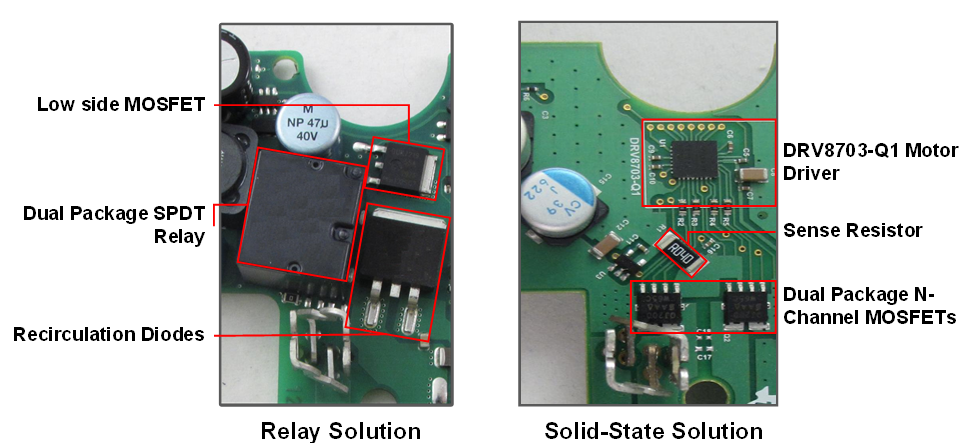

Figure 1 Relay Solution vs. Solid-state Solution

Figure 1 Relay Solution vs. Solid-state SolutionFocusing just on solution size, the solid-state 8mm-by-8mm quad flat no-lead (QFN) plus two dual-package N-channel metal-oxide semiconductor field-effect transistors (MOSFETs) is about one-third the board area of the relay solution. Looking at the z-axis, the entire solid-state solution is approximately .9 mm tall. or 0.035 inches. If you want to build a motor driver printed circuit board (PCB) that cleanly fits on the back of your motor housing, TI’s solid-state solution is well suited for this application.

Other than size, solid-state gate drivers also integrate a whole suite of protection features that would otherwise have to be built discretely in a relay solution. These features include:

Motor Current Measurement

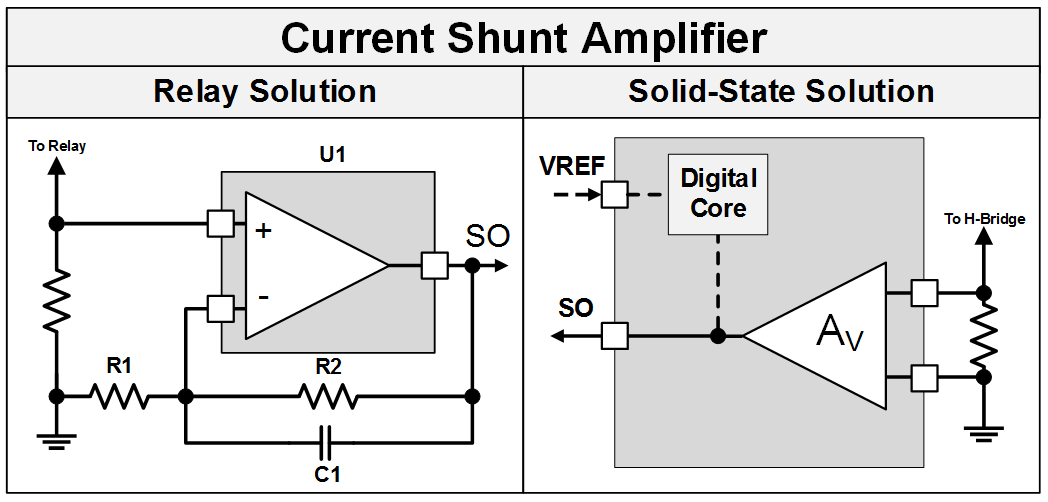

Figure 2 Discrete vs. Solid-state Current Measurement

Figure 2 Discrete vs. Solid-state Current MeasurementTI’s motor drivers took current regulation a step further and integrated a cycle-by-cycle current-chopping method using an internal comparator tied to the output of the integrated current-sense amplifier. All that’s needed is an external voltage reference and the device will handle the current limiting, freeing up resources that would otherwise be used on an MCU or built discretely. While the output of the sense amplifier still ties to a package pin, if you just need some level of current regulation, consider a fully- integrated solution, like the DRV8702-Q1 or DRV8703-Q1.

Interfacing to the MCU

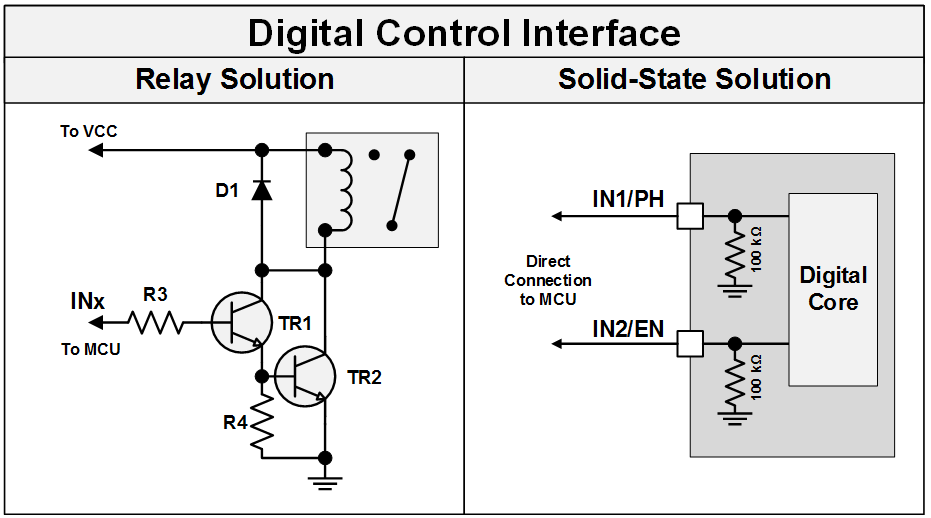

Figure 3 Interfacing to an MCU

Figure 3 Interfacing to an MCUThe relay solution in Figure 3 outlines the need for a Darlington-pair of N-doped P-doped N-doped (NPN) bipolar junction transistors (BJTs), two resistors and a protection diode all just to interface a relay coil directly with an MCU GPIO pin. In order to create an H-Bridge and drive a bidirectional motor two dual-package single-pole double-throw [SPDT] relays would be required, meaning twice the circuit components outlined above are needed to drive both relay coils independently. Using one of TI’s motor drivers allows for all of these discrete components to be removed, creating a much smaller and cleaner PCB solution.

Motor-speed Profiles

Show Me the Proof

Additional Resources

- For more solid-state motor driver reference designs, check out these reference designs from the TI reference designs library:

- Automotive 12V 200W (20A) BLDC Motor Drive Reference Design.

- Automotive 2-Axis Power Seat Brushed DC Motor Drive Reference Design.

- Automotive HVAC Multiple Flap Actuator/Damper DC Motor Driver Reference Design.

- For more information about automotive motor-driver products, see the product pages for the DRV8703D-Q1, DRV8703-Q1 and DRV8305-Q1.

- Learn more about how TI puts innovation in the driver’s seat in this blog post.

- Read more about automotive HVAC flap actuators in this blog post.