TIDUF33 june 2023

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

-

3Hardware, Software, Testing Requirements,

and Test Results

- 3.1 Hardware Requirements

- 3.2 Software Requirements

- 3.3 Test Setup

- 3.4 Test Procedure

- 3.5 Test Results

- 4Design and Documentation Support

- 5About the Author

3.4.3.4 Current Calibration

- To run this lab, make sure the hardware is set up as shown in Section 3.3.3. The 2-points calibration method is used to calibrate gain and offset errors.

- To measure current, use an external precision resistor and a DMM, or you can use E-Load current readings. Alternatively, voltage across sense resistors on the TIDA-010087 boards can be used to measure the output current.

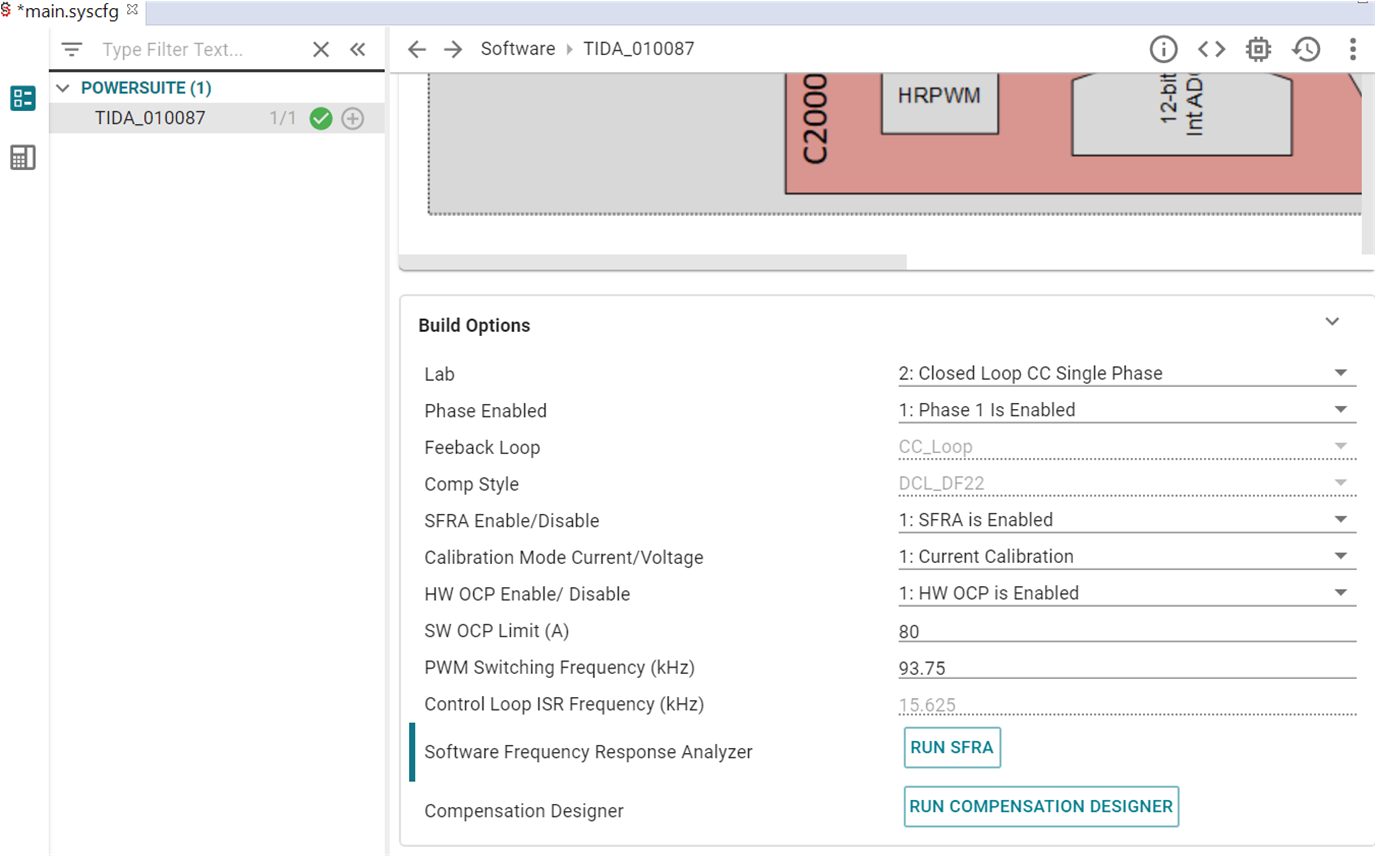

- Open the SYSCONFIG page and

select under the Build Options section:

- Select Lab 2: Closed Loop CC Single Phase for the Lab.

- Change the Phase Enabled to Phase 1.

- Set the Calibration Mode to 1 for current calibration.

- Save the SYSCONFIG page, and run the code.

- Open the Expression Window.

- The output current is updated using BT2PH_userParam_V_I_ch1->ibatCal_pu parameter.

- Set the BT2PH_enableRelay_bool to 1 to enable the output relay.

- Set the BT2PH_userParam_V_I_ch1->en_bool = 1.

- Set the BT2PH_userParam_V_I_ch1->ibatCal_pu to "0.05" and "0.3", and note the output current readings.

- Update the actual output current readings in bt2ph_cal.h file.

#define BT2PH_IBAT_ACTUAL_CH1_P1_A ((float32_t)2.6556)#define BT2PH_IBAT_ACTUAL_CH1_P2_A ((float32_t)16.163)#define BT2PH_IBAT_ACTUAL_CH2_P1_A ((float32_t)2.6556)#define BT2PH_IBAT_ACTUAL_CH2_P2_A ((float32_t)16.163)- Repeat the steps for phase 2 of the converter.

- Set the Calibration Mode to 0 disable calibration.

- When using non-powerSuite version

of the project, Build Settings are directly modified in

solution_settings.h file.

#define LAB_NUMBER (2)#define PHASE_NUMBER (1)#define CALIBRATION_ENABLED (true)#define CALIBRATION_MODE (1)

Figure 3-20 Build Options for Current

Calibration

Figure 3-20 Build Options for Current

Calibration