SCAS931G May 2012 – January 2018 CDCM6208

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Conditions

- 6.4 Thermal Information, Airflow = 0 LFM

- 6.5 Thermal Information, Airflow = 150 LFM

- 6.6 Thermal Information, Airflow = 250 LFM

- 6.7 Thermal Information, Airflow = 500 LFM

- 6.8 Single-Ended Input Characteristics (SI_MODE[1:0], SDI/SDA/PIN1, SCL/PIN4, SDO/ADD0/PIN2, SCS/ADD1/PIN3, STATUS1/PIN0, RESETN/PWR, PDN, SYNCN, REF_SEL)

- 6.9 Single-Ended Input Characteristics (PRI_REF, SEC_REF)

- 6.10 Differential Input Characteristics (PRI_REF, SEC_REF)

- 6.11 Crystal Input Characteristics (SEC_REF)

- 6.12 Single-Ended Output Characteristics (STATUS1, STATUS0, SDO, SDA)

- 6.13 PLL Characteristics

- 6.14 LVCMOS Output Characteristics

- 6.15 LVPECL (High-Swing CML) Output Characteristics

- 6.16 CML Output Characteristics

- 6.17 LVDS (Low-Power CML) Output Characteristics

- 6.18 HCSL Output Characteristics

- 6.19 Output Skew and Sync to Output Propagation Delay Characteristics

- 6.20 Device Individual Block Current Consumption

- 6.21 Worst Case Current Consumption

- 6.22 Timing Requirements, I2C Timing

- 6.23 Typical Characteristics

- 7 Parameter Measurement Information

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Description

- 8.3.1 Typical Device Jitter

- 8.3.2 Universal Input Buffer (PRI_REF, SEC_REF)

- 8.3.3 VCO Calibration

- 8.3.4 Reference Divider (R)

- 8.3.5 Input Divider (M)

- 8.3.6 Feedback Divider (N)

- 8.3.7 Prescaler Dividers (PS_A, PS_B)

- 8.3.8 Phase Frequency Detector (PFD)

- 8.3.9 Charge Pump (CP)

- 8.3.10 Fractional Output Divider Jitter Performance

- 8.3.11 Device Block-Level Description

- 8.3.12 Device Configuration Control

- 8.3.13 Configuring the RESETN Pin

- 8.3.14 Preventing False Output Frequencies in SPI/I2C Mode at Start-Up

- 8.3.15 Input MUX and Smart Input MUX

- 8.4 Device Functional Modes

- 8.5 Programming

- 8.6 Register Maps

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical Applications

- 9.2.1 Design Requirements

- 9.2.2

Detailed Design Procedures

- 9.2.2.1 Jitter Considerations in SERDES Systems

- 9.2.2.2 Jitter Considerations in ADC and DAC Systems

- 9.2.2.3 Configuring the PLL

- 9.2.2.4 Programmable Loop Filter

- 9.2.2.5 Loop filter Component Selection

- 9.2.2.6 Device Output Signaling

- 9.2.2.7 Integer Output Divider (IO)

- 9.2.2.8 Fractional Output Divider (FOD)

- 9.2.2.9 Output Synchronization

- 9.2.2.10 Output Mux on Y4 and Y5

- 9.2.2.11 Staggered CLK Output Power Up for Power Sequencing of a DSP

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- RGZ|48

Thermal pad, mechanical data (Package|Pins)

- RGZ|48

Orderable Information

9.2.2.11 Staggered CLK Output Power Up for Power Sequencing of a DSP

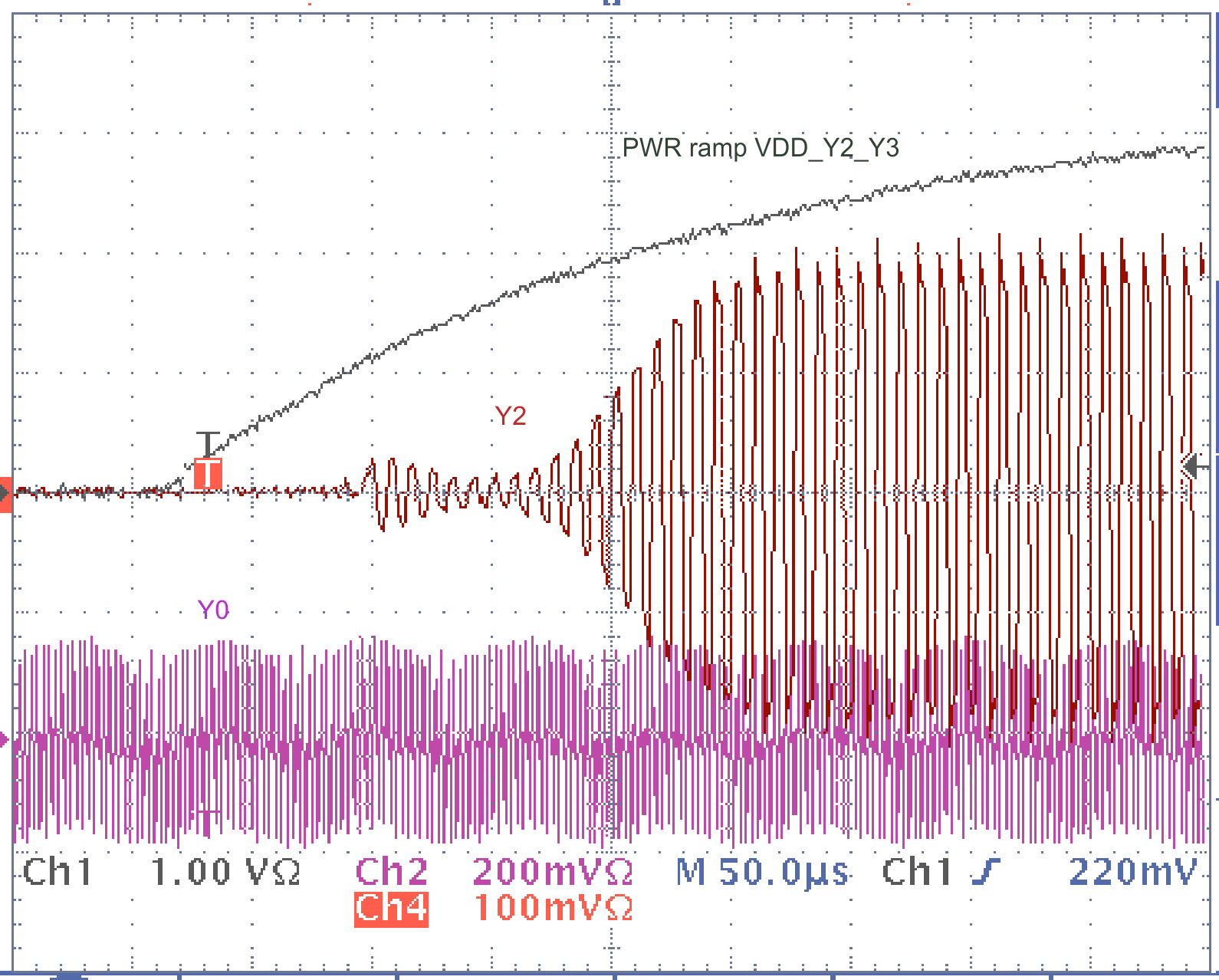

DSPs are sensitive to any kind of voltage swing on unpowered input rails. To protect the DSP from long-term reliability problems, TI recommends avoiding any clock signal to the DSP until the DSP power rail is also powered up. This can be achieved in two ways using the CDCM6208:

- Digital control: Initiating a configuration of all registers so that all outputs are disabled, and then turning on outputs one by one through serial interface after each DSP rail becomes powered up accordingly.

- Output Power supply domain control: An even easier scheme might be to connect the clock output power supply VDD_Yx to the corresponding DSP input clock supply domain. In this case, the CDCM6208 output will remain disabled until the DSP rails ramps up as well. Figure 58 shows the turnon behavior.

Figure 58. Sequencing the Output Turnon Through Sequencing the Output Supplies

Figure 58. Sequencing the Output Turnon Through Sequencing the Output SuppliesOutput Y2 Powers Up While Output Y0 is Already Running