SBOU187A april 2017 – april 2023 INA233

- Abstract

- Trademarks

- 1Overview

- 2INA233EVM Hardware

- 3INA233EVM Hardware Setup

-

4INA233EVM Software Overview

- 4.1 Starting the INA233EVM Software

- 4.2 Configuring the INA233EVM Software

- 4.3 Using the INA233EVM Software

- 5INA233EVM Documentation

- 6Revision History

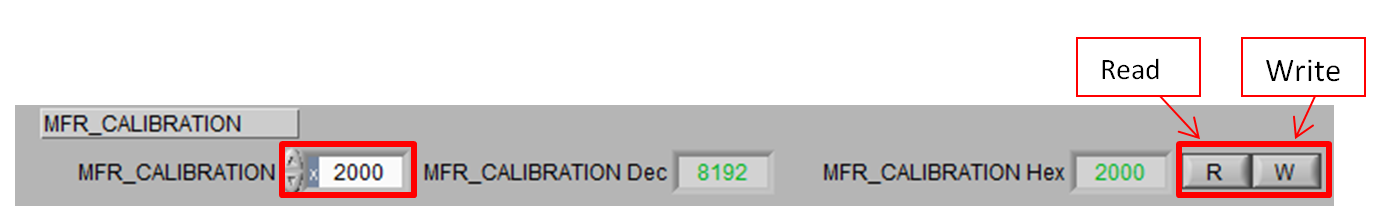

4.2.3 Set Calibration Register (MFR_CALIBRATION)

The Calibration Register must then be set correctly for the software to operate properly. The user needs to manually calculate the desired value using Equation 1 and then input that value into the MFR_Calibration box, as shown in Figure 4-7. After this, the user must press W in order to write into the Calibration Register. If inputs were correct the MFR_CALIBRATION and MFR_CALIBRATION Hex boxes should display the same values after pressing R (Pressing R reads the Calibration Register).

The current LSB is calculated by a recommended range in the INA233 data sheet as shown in Equation 2. It is important to note that the Current LSB and the Calibration Register values are calculated based on the other variable and the RSHUNT value. See the section, Programming the INA233 in the product data sheet for more information on setting the Calibration Register value.

Figure 4-7 Setting

the Calibration Register (MFR_CALIBRATION)

Figure 4-7 Setting

the Calibration Register (MFR_CALIBRATION)