SBAU321B November 2018 – June 2021 ADS7142 , ADS7142-Q1

3.2 Hardware Setup Instructions

The following are the instructions to set up the BOOSTXL-ADS7142-Q1 for evaluation:

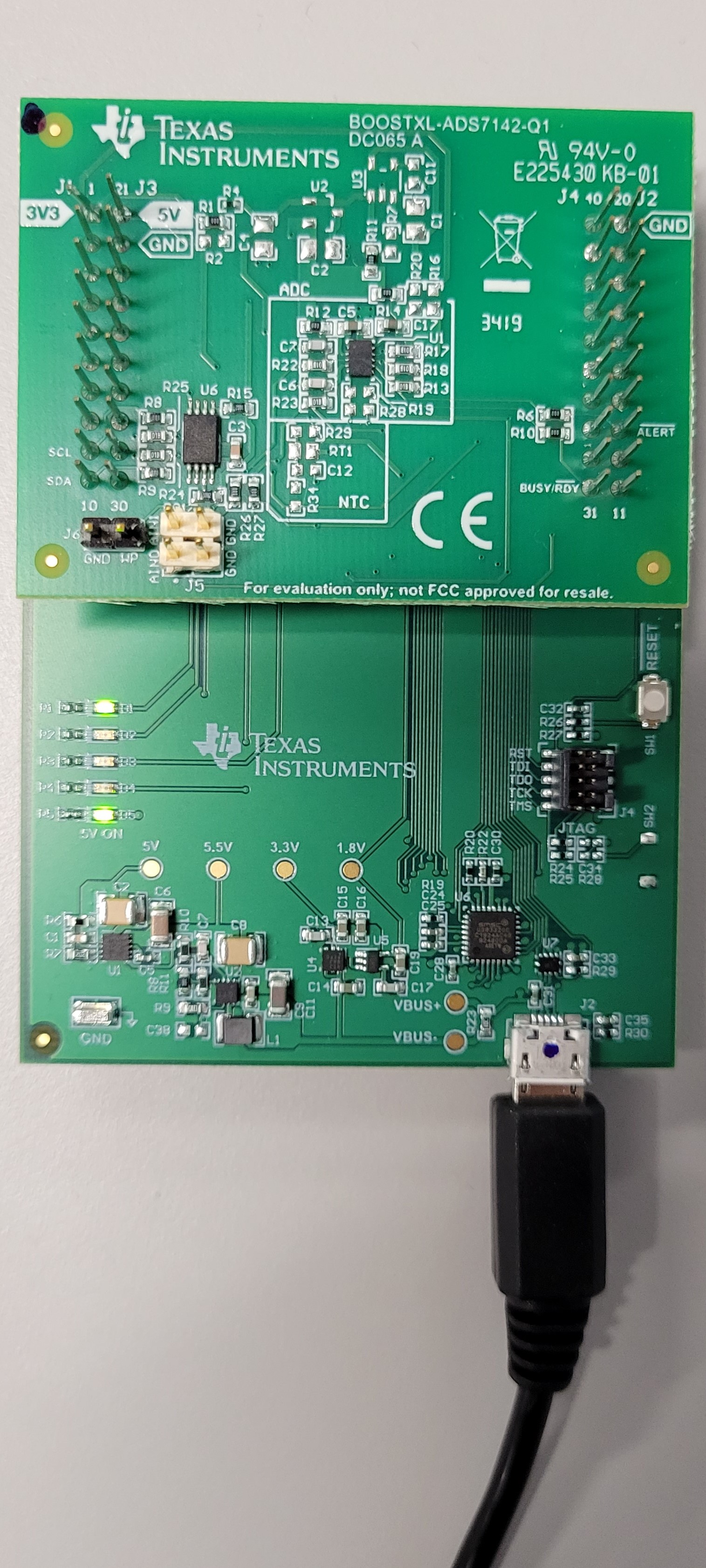

- Stack the BOOSTXL-ADS7142-Q1 on the PAMB. Make sure the 20-pin connector (J1 and J3) on BOOSTXL-ADS7142-Q1 is mapped against the left PAMB connector and the connector (J4 and J2) on BOOSTXL-ADS7142-Q1 is mapped against the right PAMB connector. Pin 1 of BOOSTXL-ADS7142-Q1 must align with pin 1 of left PAMB connector (3V3)

- Connect the micro USB from data port o PAMB to available USB port on PC.

- Figure 3-2 shows the

assembled BOOSTXL-ADS7142-Q1 and PAMB configuration.

Figure 3-2 BOOSTXL-ADS7142-Q1

Stacked on PAMBoard

Figure 3-2 BOOSTXL-ADS7142-Q1

Stacked on PAMBoard