SLAA843A August 2018 – March 2019 MSP430FR2512 , MSP430FR2512 , MSP430FR2522 , MSP430FR2522 , MSP430FR2532 , MSP430FR2532 , MSP430FR2533 , MSP430FR2533 , MSP430FR2632 , MSP430FR2632 , MSP430FR2633 , MSP430FR2633

3.1 Signal (S)

To calculate signal-to-noise ratio, it is first necessary to define signal and noise. In a capacitive touch application, the signal is defined as the average change in capacitance of the sensing electrode due to a touch or a proximity event. For example, consider a self-capacitance sensing electrode with a base, untouched parasitic capacitance Cp. If a touch capacitance, Ct, is applied to the sensing net along with Cp, the total electrode capacitance Cx = Cp + Ct. In this case, the change in capacitance expressed as a percentage of the untouched capacitance would be the quotient of Ct over Cp. Table 1 shows a simple example.

Table 1. Example of Computing Signal

| Parameter | Symbol | Value |

|---|---|---|

| Parasitic capacitance | Cp | 20 pF |

| Touch capacitance | Ct | 1 pF |

| Signal | S = Ct / Cp | (1 pF / 20 pF) × 100 = 5% |

NOTE

In mutual capacitance sensing, a touch is expected to reduce the electrode capacitance, thus showing up as a negative percent change.

In self capacitance sensing, a touch is expected to increase the electrode capacitance, thus showing up as a positive percent change. For more information about self capacitance and mutual capacitance, see the CapTIvate Technology Guide.

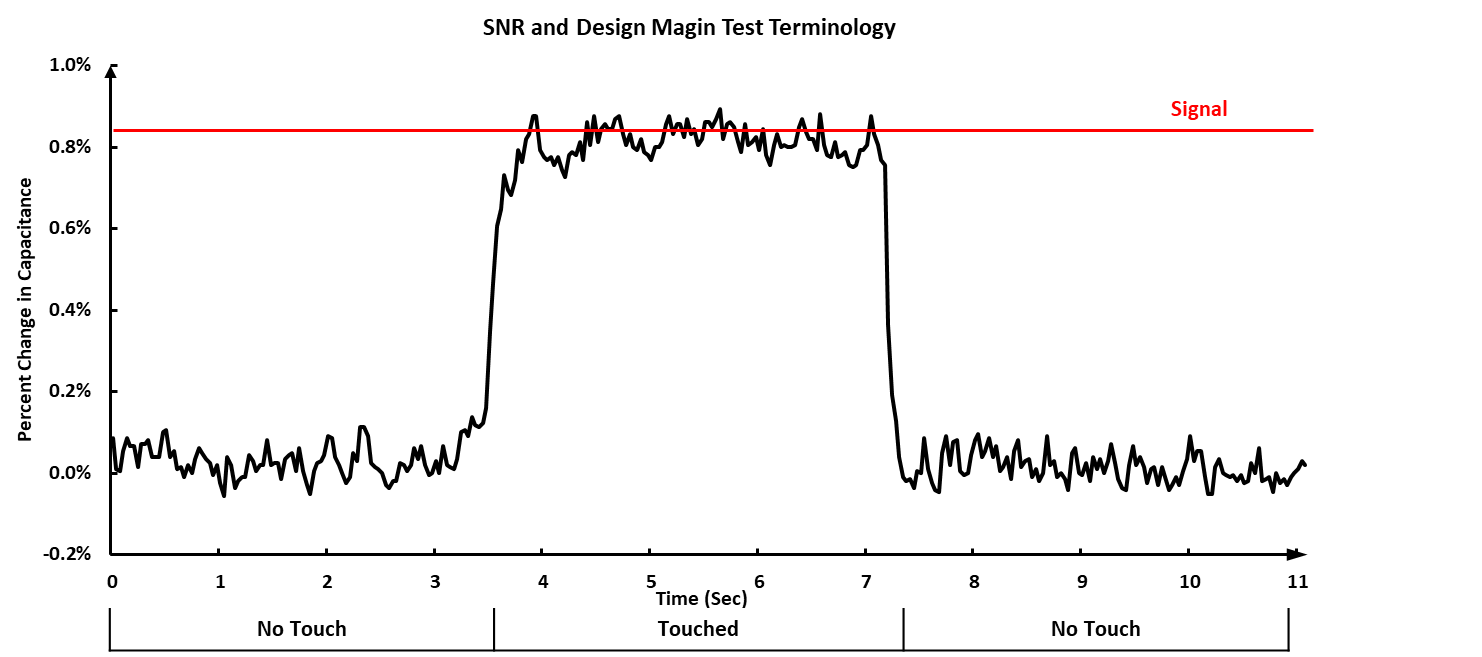

Figure 5 shows the self mode button measurement result in terms of percent change in capacitance for both touched and untouched conditions. The signal is defined as the percent change in capacitance due to a touch event (see the red "Signal" line in the figure).

Figure 5. Signal Terminology

Figure 5. Signal Terminology A fundamental concept to understand from the definition of signal is that signal is influenced not only by the touch capacitance but also by the parasitic capacitance of the electrode. This makes sense—it is easier to measure a 1-pF change in a 20-pF capacitor (5%) than it is to measure a 1-pF change in a 100-pF capacitor (1%). So, what influences Cp and Ct? Cp is primarily a function of the printed circuit board layout, including the size of the electrode and the proximity of that electrode to nearby conductors such as ground. Ct is a function of the thickness of the overlay, the dielectric constant of the overlay, and the size of the sensing electrode relative to the size of the finger touching the electrode. For details on optimizing these parameters, see the Best Practices section of the Design chapter of the CapTIvate Technology Guide.

NOTE

When measuring a physical electrode during development with a CapTIvate MCU, the CapTIvate Design Center SNR tool view can be used to measure the signal 'S' as a percent change in capacitance.