SLUP412 February 2022 LMG3522R030-Q1

- 1 Introduction

- 2 Comparing Different Technologies

- 3 Advantages of Integrating the Driver With GaN FETs

- 4 The GaN-Based 6.6-kW OBC Reference Design

- 5 PFC Stage

- 6 DC/DC Stage

- 7 DC/DC Topology Selection

- 8 Frequency Selection

- 9 Core Loss

- 10Loss of ZVS

- 11Dead Time

- 12ISR Bandwidth

- 13Overall

- 14Resonant Tank Design

- 15Thermal Solution

- 16Layout Best Practices

- 17Control-Loop Considerations

- 18Conclusions

- 19References

- 20Important Notice

18 Conclusions

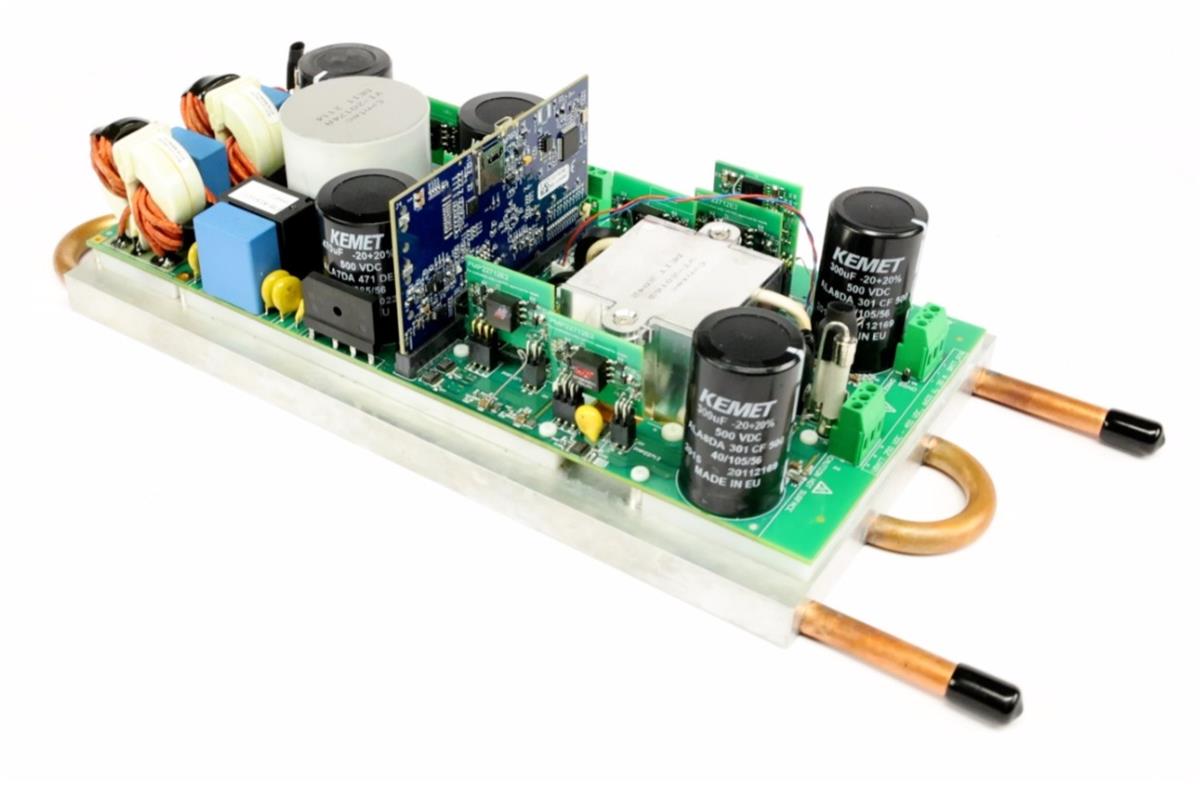

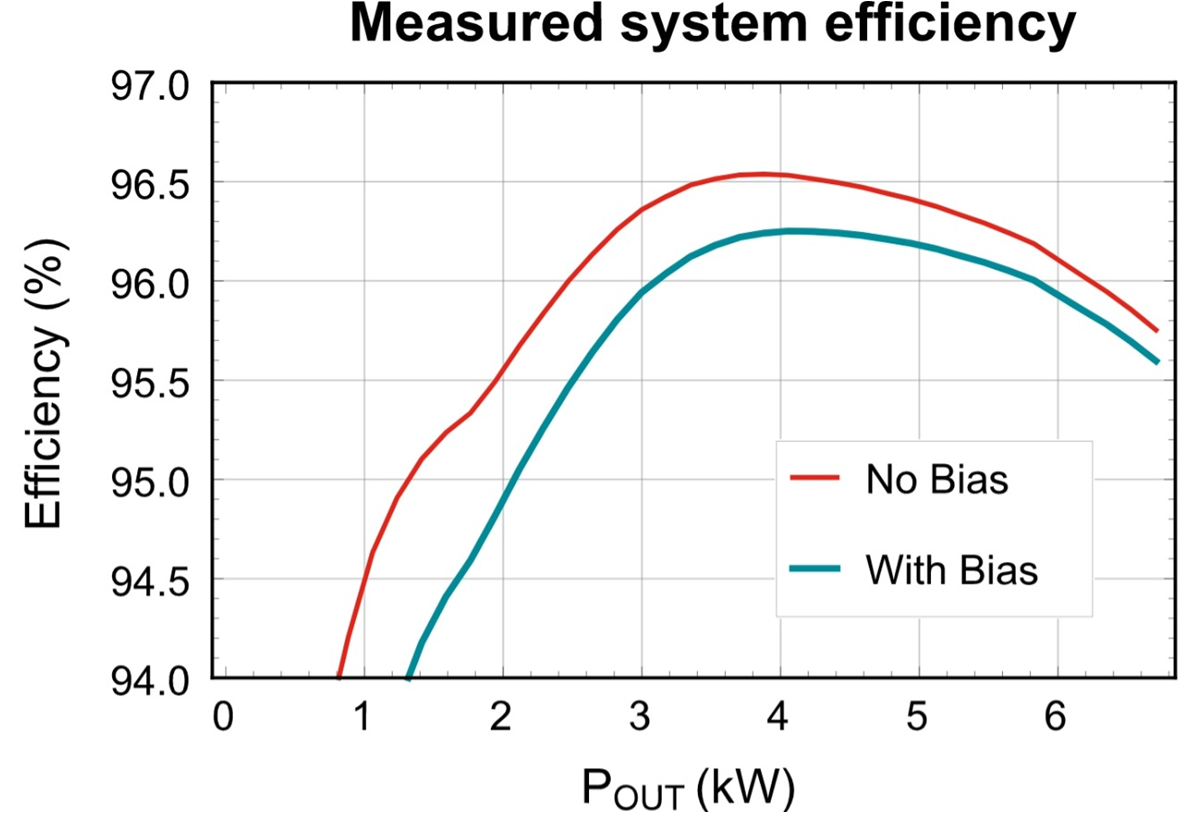

Figure 18-1 shows a picture of the final converter, while Figure 18-2 shows the end-to-end efficiency operating at the highest output current condition. The power density of the design came out at 62.5 W/inch3, or 3.8 kW/L.

Figure 18-1 6.6-kW OBC with liquid-cooled cold

plate.

Figure 18-1 6.6-kW OBC with liquid-cooled cold

plate. Figure 18-2 Measured system efficiency of the

6.6-kW OBC.

Figure 18-2 Measured system efficiency of the

6.6-kW OBC.GaN’s fast switching performance enables high-frequency power supplies that reduce size while maintaining high efficiency. With these high frequencies, a variety of challenges emerge, requiring cost-effective countermeasures that help maximize the benefits that come from high-speed switching.