SNOU173A October 2020 – December 2020 LM7310

5 Test Setup and Procedures

In this section, the test setup and procedure is described for the LM73100EVM. Make sure the evaluation board has default jumper settings as shown in Table 5-1.

Table 5-1 Default Jumper Setting for LM73100 Integrated Ideal Diode Evaluation Board

| J2 | J3 | J4 | J8 | J9 | J11 |

|---|---|---|---|---|---|

|

3-4 |

3-4 5-6 | 5-6 | 2-3 |

2-3 | 2-3 |

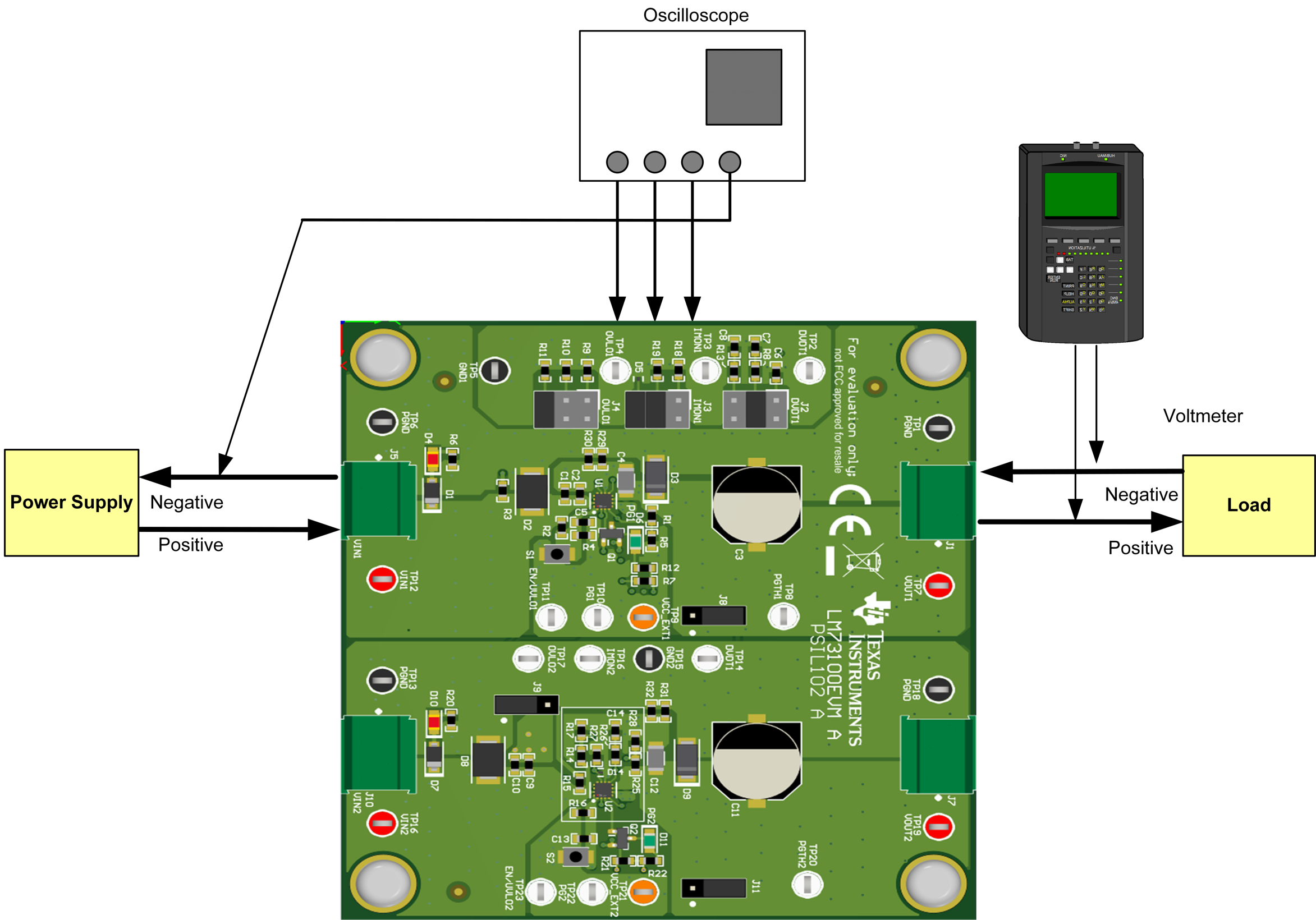

Figure 5-1 shows the LM73100EVM setup with test equipment.

Figure 5-1 LM73100EVM Setup With Test Equipment

Figure 5-1 LM73100EVM Setup With Test EquipmentFollow these instructions before starting any test and repeat again before moving to next test:

- Set the power supply output (VIN) to zero volts.

- Turn ON the power supply and set the power supply output (VIN) to 12 V, current limit = 10 A.

- Turn OFF the power supply.

- Set the jumper setting on EVM as per required setting as shown in Table 4-3.