SNOU173A October 2020 – December 2020 LM7310

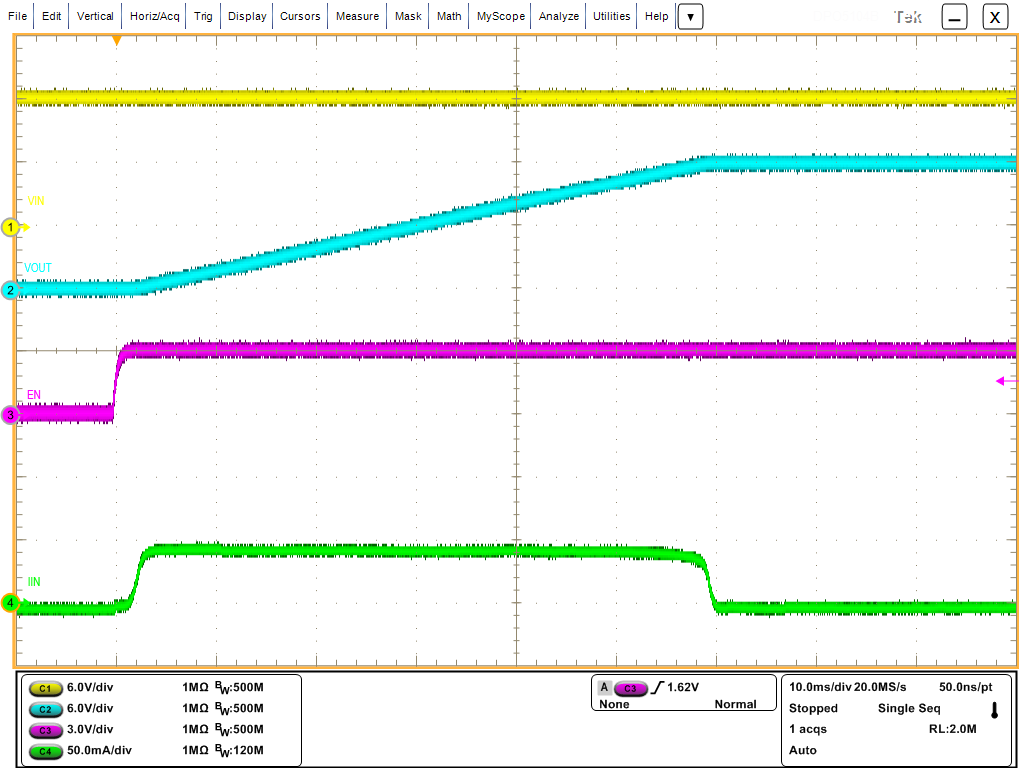

5.1 Startup Test

Use the following instructions to measure the inrush current during startup event:

- Set Jumper J2 position to desired slew rate as mentioned in Table 4-3.

Pull EN/UVLO1 to GND to disable the device.

Set the input supply voltage VIN to 12 V and current limit of 10 A. Enable the power supply.

Release the EN/UVLO1 to GND connection.

- Observe the waveform at VOUT (TP7) and input current (using current probe) with an oscilloscope to measure the slew rate and rise time of the ideal diode with a given input voltage of 12 V.

Figure 5-2 shows an example of inrush current captured on the LM73100EVM.

Figure 5-2 LM73100 Output Rise Profile (VIN = 12 V, CdVdT = 10 nF, COUT = 220 μF, No-Load)

Figure 5-2 LM73100 Output Rise Profile (VIN = 12 V, CdVdT = 10 nF, COUT = 220 μF, No-Load)