SPRAD03 March 2022 AM2431 , AM2431 , AM2432 , AM2432 , AM2434 , AM2434 , AM6411 , AM6411 , AM6412 , AM6412 , AM6421 , AM6421 , AM6422 , AM6422 , AM6441 , AM6441 , AM6442 , AM6442

- Trademarks

- 1 System Overview

- 2 Hardware Prerequisites

- 3 Hardware Configuration

- 4 HW Pinouts, Default Jumpers, and Connections

- 5 Schematics

- 6 Jumper Settings and Descriptions

- 7 LEDs

- 8 Software Architecture

- 9 Actuation and Feedback Timing

- 10Benchmark Results

-

11Detailed Demo User's Guide

- 11.1 Step 0. Getting the Software and Building

- 11.2 Step 1. Getting Started With the Hardware

- 11.3 Step 2. Configure ROQ437 EnDat2.2 Encoder for Faster EnDat 2.2 Recovery Time (only needs to be done once the first time you use the ROQ437 encoder)

- 11.4 Step 3. Open Loop Iq Control (BUILDLEVEL == OPEN_LOOP_IQ_ID)

- 11.5 Step 4. Closed Loop Iq/Id Control (BUILDLEVEL == CLOSED_LOOP_IQ_ID)

- 11.6 Step 5. Closed Loop Speed Control (BUILDLEVEL == CLOSED_LOOP_SPEED)

- 11.7 Step 6. Closed Loop Position Control (BUILDLEVEL == CLOSED_LOOP_POSITION)

- 12Build Using MCU+SDK 08.00.00.21 & CCS 10.3.1

- 13Summary

- 14Appendix A: Detailed Motor Control R5F Processing Time

- 15References

11.7 Step 6. Closed Loop Position Control (BUILDLEVEL == CLOSED_LOOP_POSITION)

This build level closes the position loop in addition to the speed and current loops.

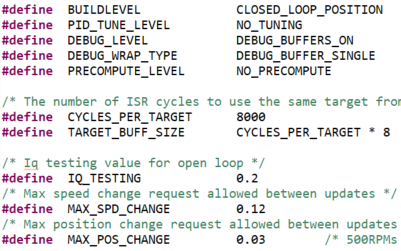

- Go to the settings.h file and

change the definitions to match the following (closed loop position control,

debug buffers on, 8000 cycles per set point):

Figure 11-28 Closed Loop Position -

BUILDLEVEL

Figure 11-28 Closed Loop Position -

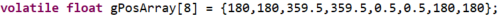

BUILDLEVEL - If desired, go to the

single_chip_servo.c file and modify the Speed set point array. Default values

shown below.

- Values are duplicated to give the motor time to get to the position before the setpoint cycle count is up.

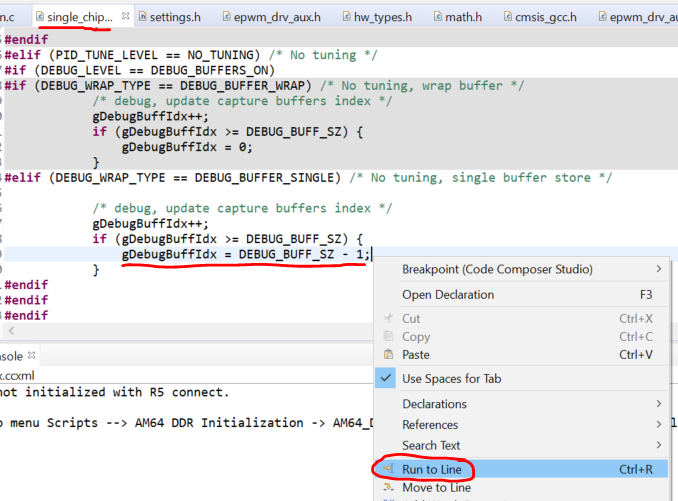

- Once the project is loaded, open

the 'single_chip_servo.c' file and find the following line, then right-click and

select 'Run to Line'.

Figure 11-29 Closed Loop Position -

Run to Line

Figure 11-29 Closed Loop Position -

Run to Line - Running to this line allows the control code to run through the eight different setpoints and fill up the debug buffer so that the grap can be viewed.

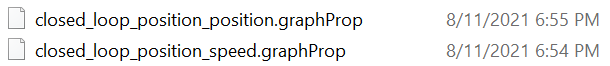

- Check

the output by importing the following graphs:

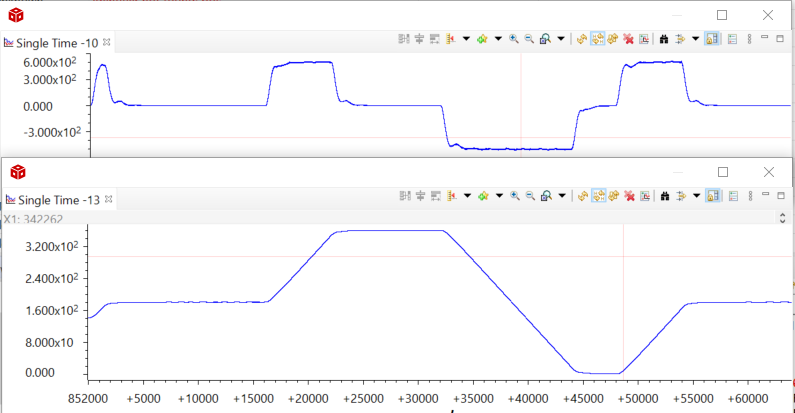

Figure 11-30 Closed Loop Position -

Position and Speed Graph 1

Figure 11-30 Closed Loop Position -

Position and Speed Graph 1 - Example output shown below (speed

and position graphed from top to bottom). Notice how speed goes to +-500RPMs

during the position changes and stays there until the position is reached. The

position ramp slope is determined by the MAX_POS_CHANGE definition in the

settings.h file.

Figure 11-31 Closed Loop Position -

Position and Speed Graph 2

Figure 11-31 Closed Loop Position -

Position and Speed Graph 2 - It is a difficult to see how

accurate the position is in the CCS graph above, so you can also use the CCS

memory browser to dump 'gDebugBuff5' to a text file in order review in Excel or

Matlab. Once you do that, you can see how accurate the position actually is:

typically +-0.001° from the requested target once the position has settled

(shown in Figure 11-32 for two of the requested positions):Figure 11-32 Closed Loop Position - Position Control Accuracy