SSZTAE2 february 2017 AM5706 , AM5708 , AM5746 , AM5748

In today’s competitive market environment, two paths to success come from improved production and supply chain efficiency. These improvements range from increasing machine reliability to streamlining their ease of use or providing more accurate data for their operations. All of these concepts can be addressed based on how information moves through a factory using industrial automation systems.

What Is Happening in My Factory?

To keep machines running smoothly, operators must quickly identify when errors might happen on a production line. For example, a soda bottling machine may need to alert operators to replenish soda levels based on the remaining volume. Once a system senses this deficiency, status updates are then displayed through a human-machine interface (HMI) on handheld devices, in large control rooms or on the machine itself. HMIs can range from simple segmented displays to high-resolution LCD displays.

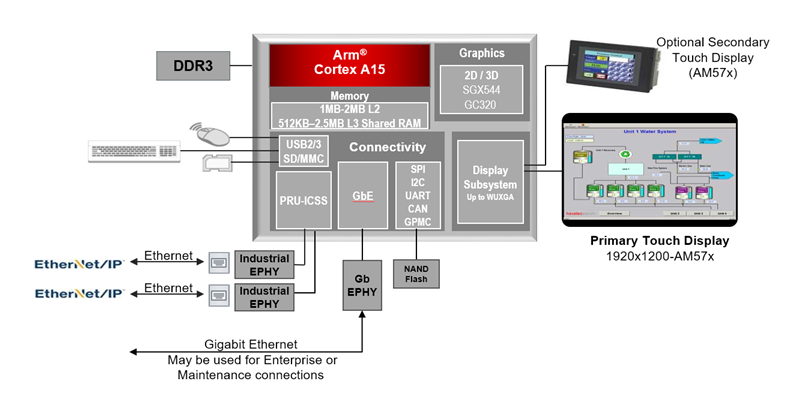

Display systems typically include an application processor to run operating systems like Linux or VXWorks®, which enable access to frameworks like Qt for designing a graphical user interfaces (GUIs). Some processors even include graphic accelerators to provide sophisticated graphic processing while easing the load on the main processor. A wide range of 2D or 3D display capabilities are available on TI’s Sitara™ processors based on the ARM core.

Now that data can be displayed through an HMI, it needs to gather data from the rest of the factory.

How Does Data Travel through the Network?

A network of sensors captures products’ information as they move down a production line and connect to programmable logic controllers (PLCs) through low-latency real-time networks. These networks use specialized industrial Ethernet communication protocols to send information within milliseconds, ensuring that a PLC transmits actions to connected devices faster than any human could. Additionally, industrial Ethernet protocols often use redundancy measures to ensure that information gets delivered in case of a network disruption.

When using Sitara processors, these industrial communications can run on the programmable real time unit and industrial communication sub system (PRU-ICSS). The extra PRU cores allow for the implementation of multiple protocols, making it easy to program many different protocols using the same device, instead of using a custom ASIC device for each protocol, saving time and resources. Having a reprogrammable device, means that factories do not need to change their entire network in order to connect different elements together.

These Ethernet networks can cover many of the factory needs, but wireless connectivity can provide a better solution.

How Can I Use Wi-Fi to Increase Connectivity?

Factories often utilize large machinery with feature displays or access points that are difficult for a human operator to access, such as controls located high above the ground or displays mounted in cramped spaces. To get information from those hard-to-reach places, Wi-Fi sensors can relay data to a more convenient location (e.g. a control room). And by incorporating cloud services, factory workers can not only access this specific information through a smartphone application, but also historical data or statistics on a particular piece of machinery.

TI’s WiLink™ 8 modules allow engineers to easily add Wi-Fi® and Bluetooth®/ Bluetooth Low Energy connectivity to many devices, perfectly pairing with Sitara processors for Industrial Automation. Features include:

- Scalable pin-to-pin compatible modules accommodate changing designs and requirements

- Industrial temperature grade module options

- Mesh networking for range extension

Get started now with the TI WiLink™ 8 and Sitara AM570x processor in 3 easy steps.