SSZTBR8 december 2015 DLP6500FLQ , DLP7000 , DLP7000UV , DLP9000 , DLP9000X , DLP9500 , DLP9500UV , DLPC910

The printing method called lithography has come a long way since its invention in Germany in the 1700s. Today, lithography prints text and images onto a variety of surfaces, from books to t-shirts.

A variation of this printing technology continues to spur new innovation. Called direct imaging photolithography, it’s being deployed by designers to “print” a variety of electronics products quickly and easily through a process that exposes photosensitive materials to ultraviolet (UV) light.

Modern direct imaging lithography can be used to make printed circuit boards (PCBs), ball Grid Arrays (BGA), chip scale packages (CSP), flat panel displays, real time barcode marking, and in direct computer-to-plate printing, a type of printing process in which a digital image is transmitted directly from a computer to a plate used on a press.

The benefits of direct imaging lithography are many, including greater material flexibility, reduced costs and greater printing speed when compared to traditional lithography techniques.

Direct Imaging Photolithography Powered by TI

At TI, our DLP® high speed digital micromirror devices (DMDs) are a powerful option for direct imaging photolithography developers who require accuracy down to the micron, with fast exposure times for volume manufacturing and reduced operational costs.

Using programmable light steering DLP technology, a developer can directly expose patterns onto photoresist films without the need for contact masks. This reduces material cost, improves production rates and allows for rapid changes of the pattern, which is ideal when minimum feature sizes require double exposure.

TI’s highly flexible chipset architectures also provide multiple system control and connectivity options such as triggers for motor synchronization, sensors and other peripherals.

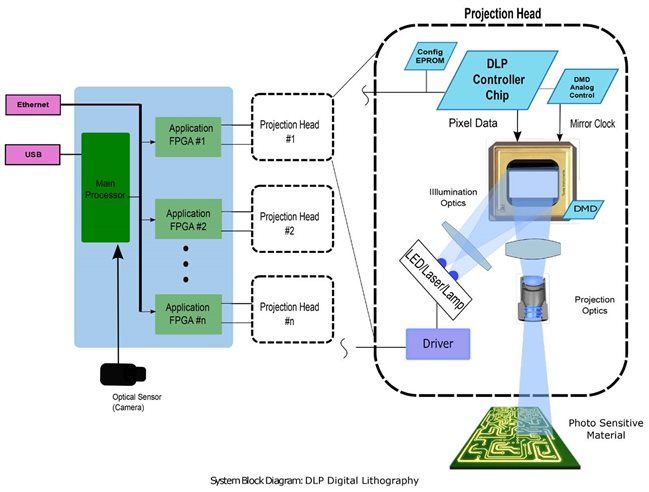

A Typical System Block Diagram of DLP Direct Imaging Lithography

See How DLP Maskless Lithography Is Reducing Costs and Increasing Reliability for PCBs in This Video

Learn More about Lithography

We have multiple DLP digital micromirror devices suitable for lithography applications. The DLP6500FLQ, DLP7000, DLP9000, and DLP9500 chipset families all support wavelengths down to 400nm. Most recently, we’ve released the DLP7000UV and DLP9500UV on ti.com to support wavelengths down to 363nm.

TI offers a portfolio of evaluation modules for all of our DMDs, and a supporting TI Designs Reference Design for lithography with schematics, layout files, a bill of materials and a test report.

The TI Design features a system-level DLP development board with maximum throughput by integrating the DLP9000X – our highest resolution DLP digital micromirror device made of more than 4 million micromirrors – with our fastest digital controller, the DLPC910 supporting up to 60 giga pixel per second data rates. The DLPC910 digital controller also offers designers advanced pixel control with random row addressing in addition to full frame input capabilities.

To read more about DLP technology for lithography, visit this page.