SLVSBM9E October 2013 – September 2018 LMZ31520

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Specifications

- 5 Device Information

- 6 Typical Characteristics (PVIN = VIN = 12 V)

- 7 Typical Characteristics (PVIN = VIN = 5 V)

-

8 Application Information

- 8.1 Adjusting the Output Voltage

- 8.2 Frequency Select

- 8.3 Capacitor Recommendations for the LMZ31520 Power Supply

- 8.4 Transient Response

- 8.5 Application Curves Device configured for FCCM mode of operation, (pin 3 connected to pin 19).

- 8.6 Application Schematics

- 8.7 Custom Design With WEBENCH® Tools

- 8.8 VIN and PVIN Input Voltage

- 8.9 3.3 V PVIN Operation

- 8.10 Power Good (PWRGD)

- 8.11 Slow Start (SS_SEL)

- 8.12 Auto-Skip Eco-mode / Forced Continuous Conduction Mode

- 8.13 Power-Up Characteristics

- 8.14 Pre-Biased Start-Up

- 8.15 Remote Sense

- 8.16 Output On/Off Inhibit (INH)

- 8.17 Overcurrent Protection

- 8.18 Current Limit (ILIM) Adjust

- 8.19 Thermal Shutdown

- 8.20 Layout Considerations

- 8.21 EMI

- 9 Revision History

- 10Device and Documentation Support

- 11Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- RLG|72

Thermal pad, mechanical data (Package|Pins)

Orderable Information

8.17 Overcurrent Protection

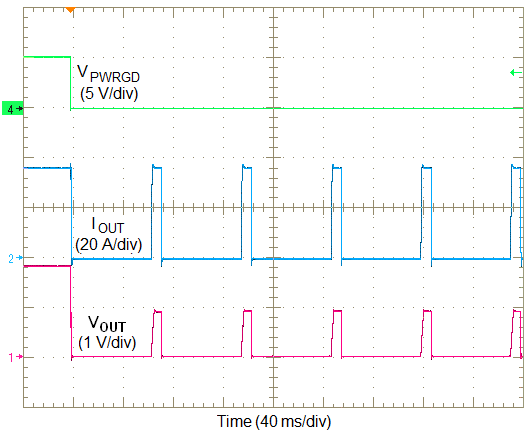

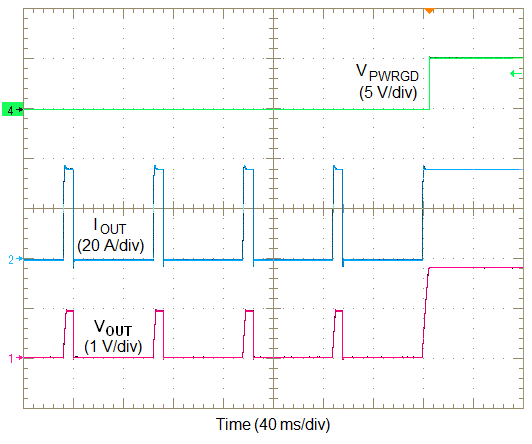

For protection against load faults, the LMZ31520 incorporates cycle-by-cycle overcurrent limiting control. The inductor current is monitored during the OFF state and the controller maintains the OFF state during the period in that the inductor current is larger than the overcurrent trip level. In cycle-by-cycle mode, applying a load that exceeds the regulator's overcurrent threshold limits the output current and reduces the output voltage as shown in Figure 23. If the overcurrent condition remains and the output voltage drops below 70% of the set-point, the LMZ31520 shuts down. Following shutdown, the module periodically attempts to recover by initiating a soft-start power-up as shown in Figure 23. This is described as a hiccup mode of operation, whereby the module continues in a cycle of successive shutdown and power up until the load fault is removed. During this period, the average current flowing into the fault is significantly reduced which reduces power dissipation. Once the fault is removed, the module automatically recovers and returns to normal operation as shown in Figure 24.

Figure 23. Typical Overcurrent Limiting

Figure 23. Typical Overcurrent Limiting  Figure 24. Typical Removal of Overcurrent

Figure 24. Typical Removal of Overcurrent