JAJSF86F April 2010 – April 2018 DLPC200

PRODUCTION DATA.

- 1 特長

- 2 アプリケーション

- 3 概要

- 4 改訂履歴

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 Handling Ratings

- 6.3 Recommended Operating Conditions

- 6.4 Thermal Information

- 6.5 I/O Electrical Characteristics

- 6.6 Video Input Pixel Interface Timing Requirements

- 6.7 I2C Interface Timing Requirements

- 6.8 USB Read Interface Timing Requirements

- 6.9 USB Write Interface Timing Requirements

- 6.10 SPI Slave Interface Timing Requirements

- 6.11 Parallel Flash Interface Timing Requirements

- 6.12 Serial Flash Interface Timing Requirements

- 6.13 Static RAM Interface Timing Requirements

- 6.14 DMD Interface Timing Requirements

- 6.15 DLPA200 Interface Timing Requirements

- 6.16 DDR2 SDR Memory Interface Timing Requirements

- 6.17 Video Input Pixel Interface – Image Sync and Blanking Requirements

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1

DLPC200 System Interfaces

- 8.2.2.1.1 DLPC200 Master, I2C Interface for EDID Programming

- 8.2.2.1.2 USB Interface

- 8.2.2.1.3 Bus Protocol

- 8.2.2.1.4 SPI Slave Interface

- 8.2.2.1.5 Parallel Flash Memory Interface

- 8.2.2.1.6 Serial Flash Memory Interface

- 8.2.2.1.7 SRAM Interface

- 8.2.2.1.8 DDR2 SDR Memory Interface

- 8.2.2.1.9 Projector Image and Control Port Signals

- 8.2.2.1.10 SDRAM Memory

- 8.2.2.1

DLPC200 System Interfaces

- 8.2.3 Application Curve

- 9 Power Supply Recommendations

- 10Layout

- 11デバイスおよびドキュメントのサポート

- 12メカニカル、パッケージ、および注文情報

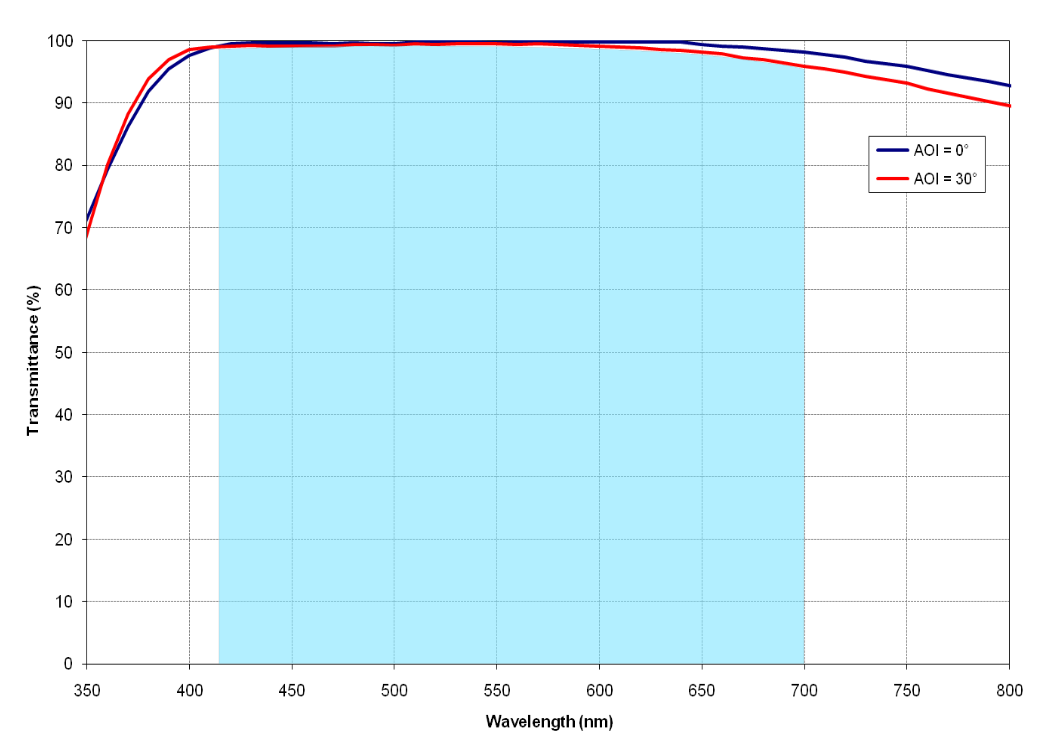

8.2.3 Application Curve

The DLPC200 is used to control the DLP5500 0.5-inch XGA DMD. This device can be used for numerous applications in the visible range of the spectrum such as 3D printing or structured light. Figure 16 shows single-pass window transmission for 0° and 30° angles of incidence. The area from 420 to 700 nm (light blue) is the range specified for operation of the DLP5500.