SLVUBO3A April 2019 – October 2020 TPS650330-Q1

- Trademarks

- 1BOOSTXL-TPS65033 Components and Environment

- 2BOOSTXL-TPS65033 Board Information

- 3Programming GUI Operation

- 4Recommended Operating Procedure

- 5BOOSTXL-TPS65033 Schematic

- 6BOOSTXL-TPS65033 Board Layers

- 7BOOSTXL-TPS65033 Bill of Materials

- 8Revision History

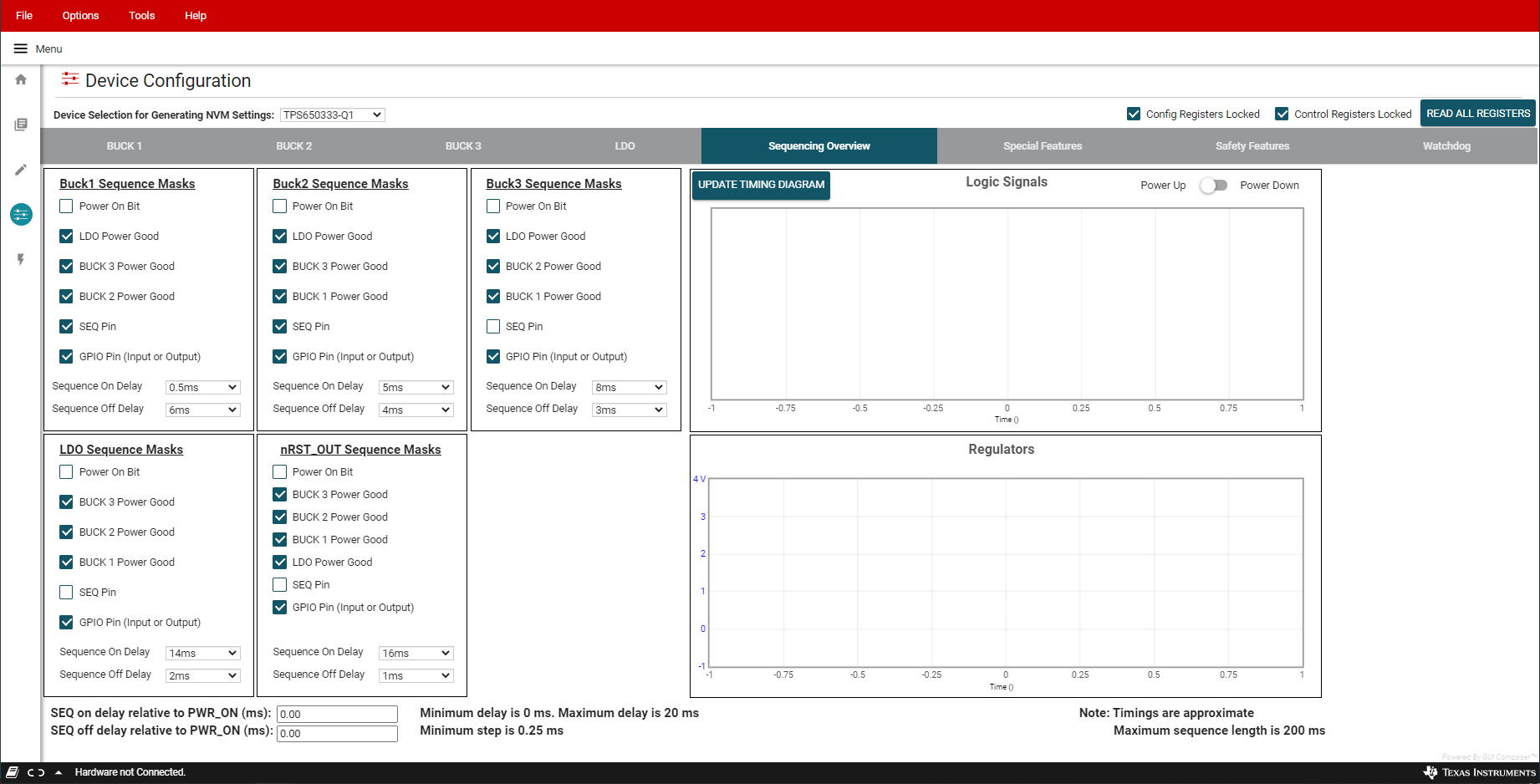

3.3.4.2 Configuring the Power Sequence

The Sequencing Overview tab includes instruments to customize the power sequence of the PMIC. Note that the check boxes are power sequence masks. If a particular logic signal needs to be included as part of the regulator or logic power up sequence, leave the box next to the logic signal unchecked. TI recommends to set Power On Bit unmasked for each rail that is required in the application.

Figure 3-18 Sequencing Overview

Tab

Figure 3-18 Sequencing Overview

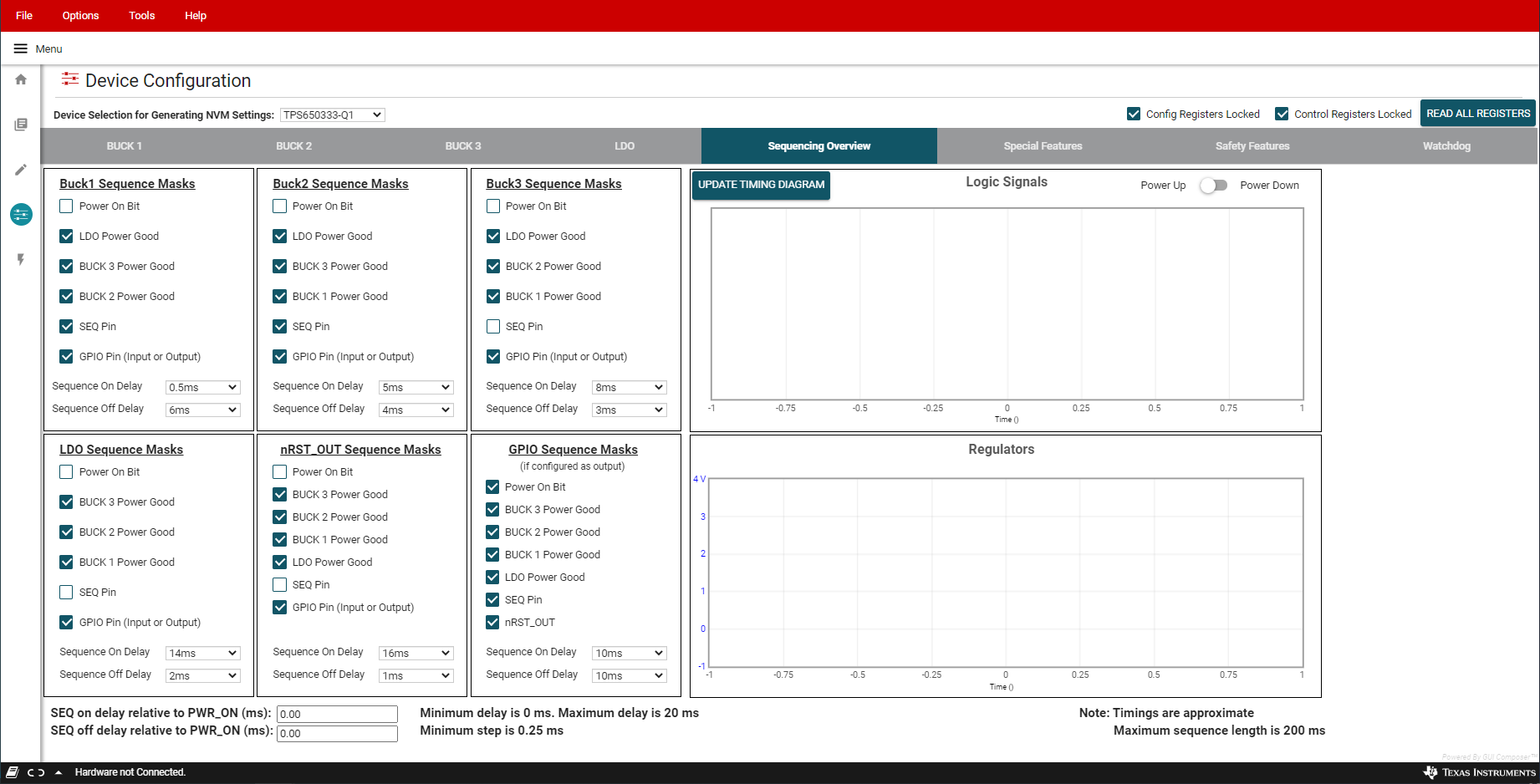

Tab Figure 3-19 Sequencing Overview Including

GPIO

Figure 3-19 Sequencing Overview Including

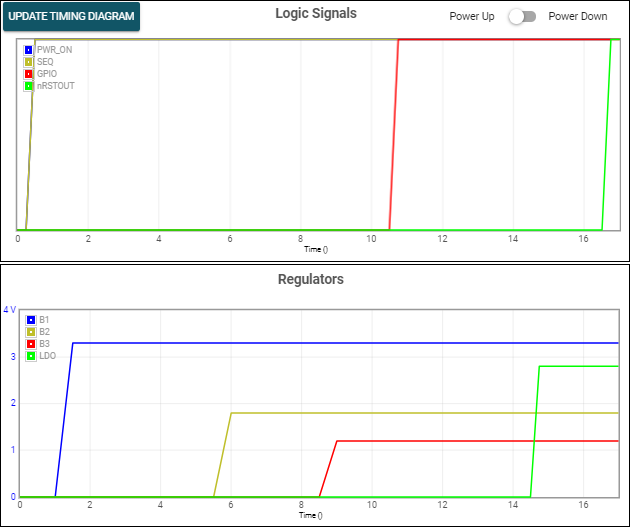

GPIO Figure 3-20 GUI Generated Timing Diagram

Figure 3-20 GUI Generated Timing Diagram