SNIA044 November 2021 TMP61 , TMP61-Q1 , TMP63 , TMP63-Q1 , TMP64 , TMP64-Q1

2 Component Temperature Monitoring With Adjacent PCB Placement

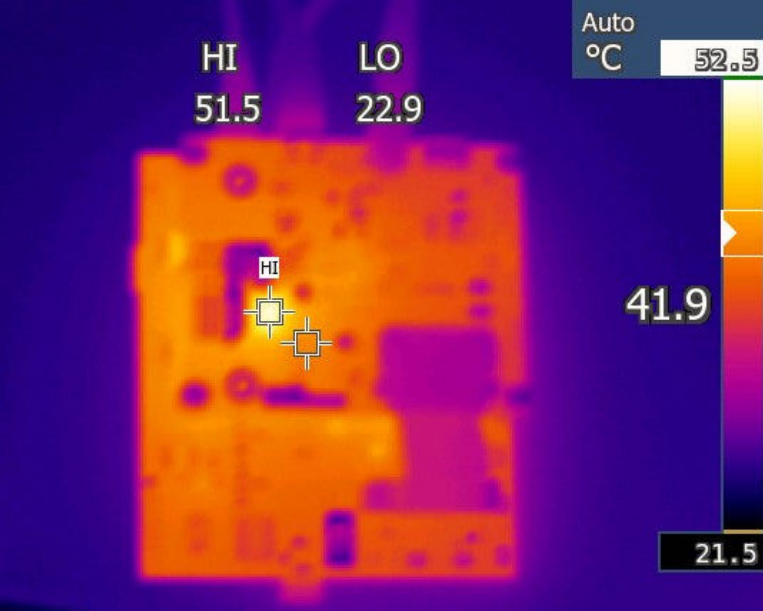

The most common method of monitoring the temperature of a critical component is to place a temperature sensor directly next to the component. Heat conducts to the sensor via the PCB and traces. This method is cheap and simple, but thermal interference from ambient temperature and heat from other components on the board affect the temperature sensor. The heat radiated from the critical component can also decay very quickly, especially when the temperature differential between the component and ambient is very high. Figure 2-1 shows a thermal capture of the AWR2243BOOST evaluation module (EVM) mounted onto the DCA1000EVM for data capture. The HI temperature reading shows that the AWR2243, operating at a moderate load, has reached a temperature of 51.5°C. The LO value is the ambient temperature of 22.9°C, and the board temperature as measured by the thermal camera is 41.9°C.

Figure 2-1 Thermal Capture of

AWR2243BOOST Under Moderate Load

Figure 2-1 Thermal Capture of

AWR2243BOOST Under Moderate LoadAs shown, the quality of temperature data declines as distance from the radar chip on the PCB increases. By placing a temperature sensor adjacent to the AWR2243, the measured temperature even a few centimeters away from the heat source will be several degrees Celsius less than the actual die temperature of the device. This is due to the various thermal resistances between the component and the location of the temperature sensor.

Furthermore, there are often temperature gradients on the die blocks of the chips themselves. When monitoring critical components, it is important to accurately monitor the temperature of the precise hot spot of the device, which can be difficult if using only one adjacent external temperature sensor.

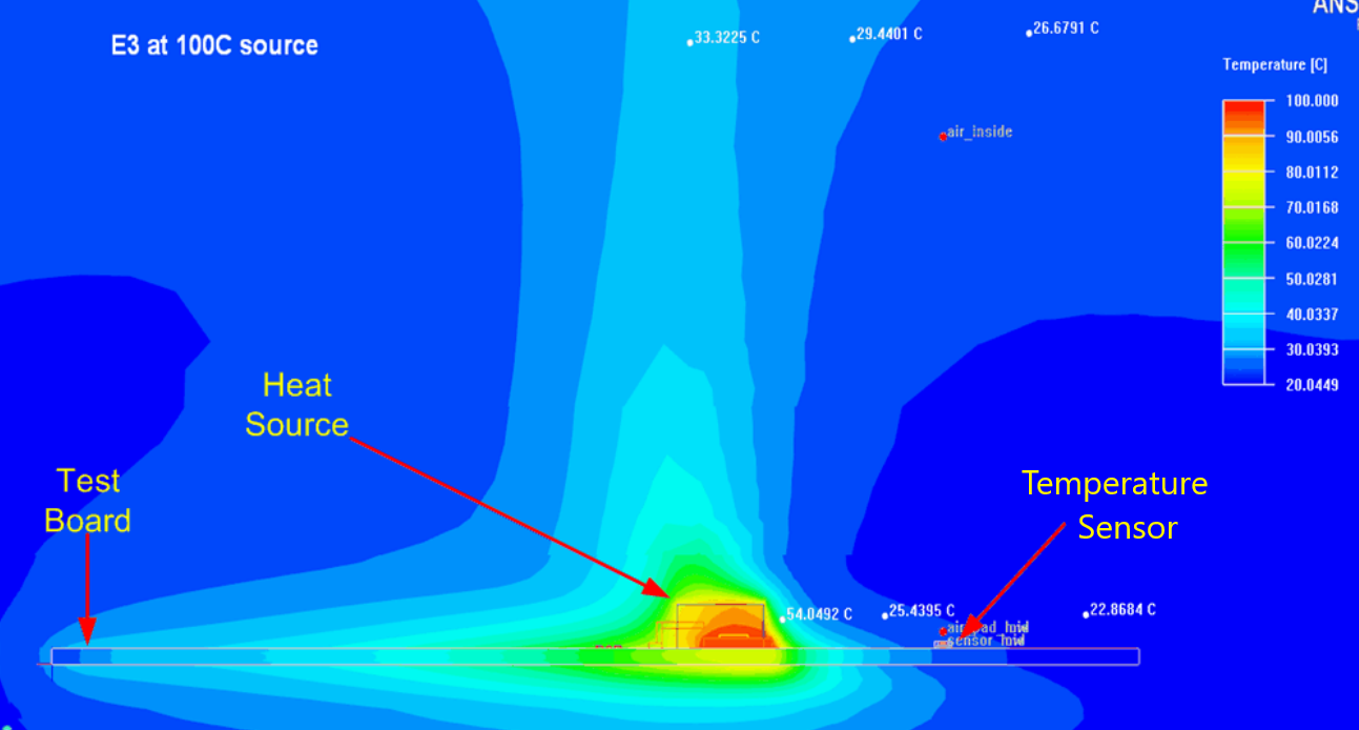

Finally, Figure 2-2 shows a thermal simulation of a test board with a temperature sensor near a 100°C heat source. The temperature at the temperature sensor is significantly lower than the temperature of the heat source due to the thermal resistances between the two. There are techniques to compensate for these thermal resistances and estimate the die temperature from one external temperature measurement, but the exact thermal resistances are difficult or even impossible to determine, making it difficult to accurately measure the die temperature of the device across a wide temperature range.

Figure 2-2 Thermal Simulation of

Temperature Sensor Near 100°C Heat Source

Figure 2-2 Thermal Simulation of

Temperature Sensor Near 100°C Heat SourceFrom the examples provided, it is evident that a different technique is necessary to accurately monitor the temperature of certain components using external sensors. One effective technique is to use differential temperature measurements.