TIDUCL0 January 2017

- 1 Description

- 2 Resources

- 3 Features

- 4 Applications

- 5 Design Images

- 6 System Overview

-

7 System Design Theory

- 7.1 Power Stage Design—Battery Power Input to the Board

- 7.2 Power Stage Design—Three-Phase Inverter

- 7.3 Power Stage Design—DRV8323 Gate Driver

- 7.4 Power Stage Design—18-V to 3.3-V DC-DC Converter

- 7.5 Power Stage Design —Microcontroller MSP430

- 7.6 Power Stage Design—Hall Sensor Interface

- 7.7 Temperature Sensing

- 7.8 Power Stage Design—External Interface Options and Indications

- 8 Getting Started Hardware and Software

- 9 Testing and Results

- 10Design Files

- 11Software Files

- 12Related Documentation

- 13Terminology

- 14About the Author

9.2.1.2 Gate Drive Voltage Generated by Gate Driver

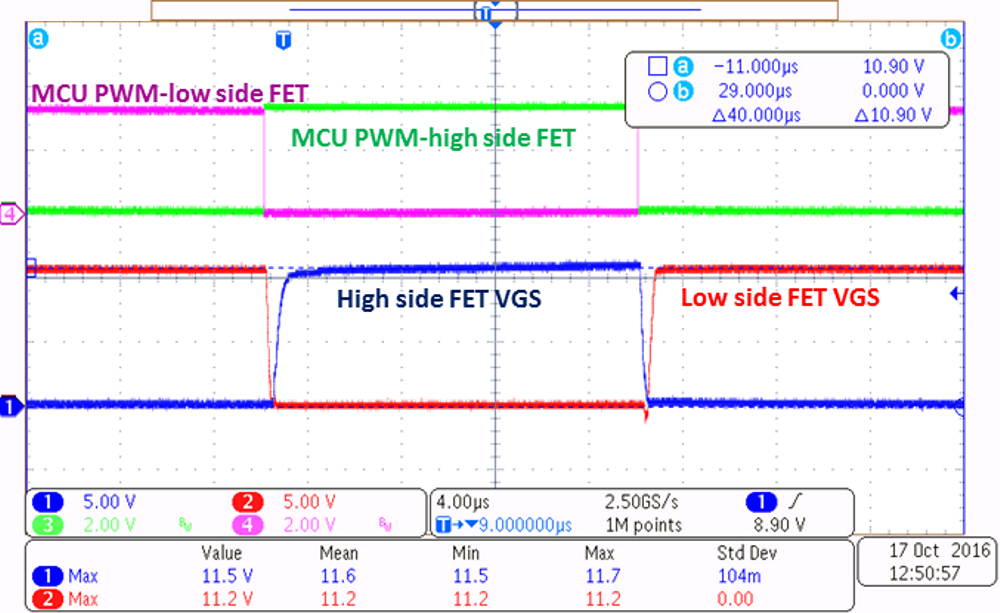

Figure 19 shows the gate drive output voltage of DRV8323 and the corresponding MCU PWM signals at a DC bus voltage of 18-V DC. The gate drive voltage is approximately 11 V, which means effective gate driving of standard MOSFETs.

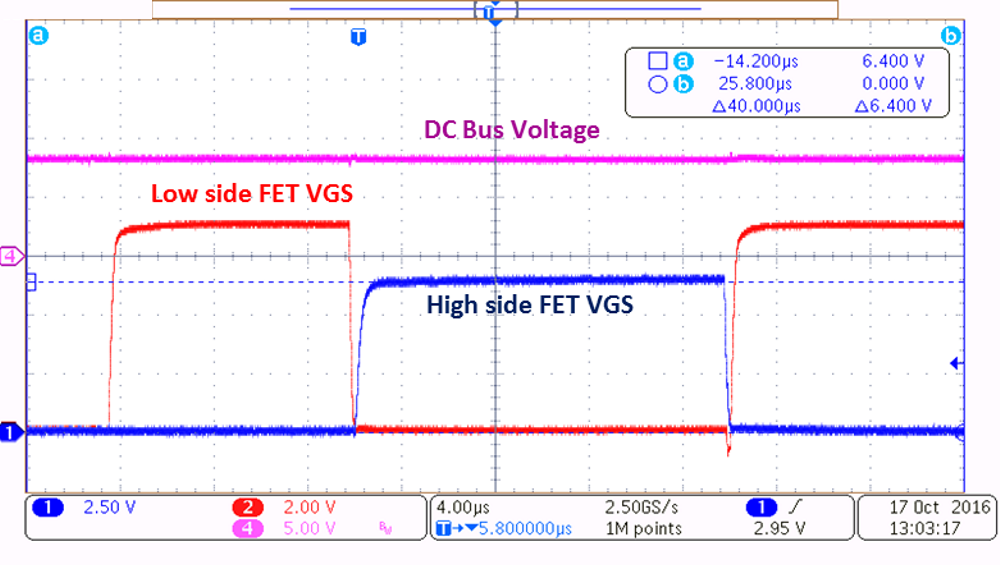

Figure 20 shows the gate drive voltage of the DRV8323 at a DC bus voltage of 8 V, which could be the minimum voltage available from a discharged Li-ion battery. The gate drive output voltage is approximately 6.5 V.

Figure 19. Low-Side and High-Side Gate Drive Voltage at 18-V DC

Figure 19. Low-Side and High-Side Gate Drive Voltage at 18-V DC  Figure 20. High-Side and Low-Side Gate Drive Voltage at 8-V DC

Figure 20. High-Side and Low-Side Gate Drive Voltage at 8-V DC