TIDUCL0 January 2017

- 1 Description

- 2 Resources

- 3 Features

- 4 Applications

- 5 Design Images

- 6 System Overview

-

7 System Design Theory

- 7.1 Power Stage Design—Battery Power Input to the Board

- 7.2 Power Stage Design—Three-Phase Inverter

- 7.3 Power Stage Design—DRV8323 Gate Driver

- 7.4 Power Stage Design—18-V to 3.3-V DC-DC Converter

- 7.5 Power Stage Design —Microcontroller MSP430

- 7.6 Power Stage Design—Hall Sensor Interface

- 7.7 Temperature Sensing

- 7.8 Power Stage Design—External Interface Options and Indications

- 8 Getting Started Hardware and Software

- 9 Testing and Results

- 10Design Files

- 11Software Files

- 12Related Documentation

- 13Terminology

- 14About the Author

9.2.7 Testing for Peak Current Capability

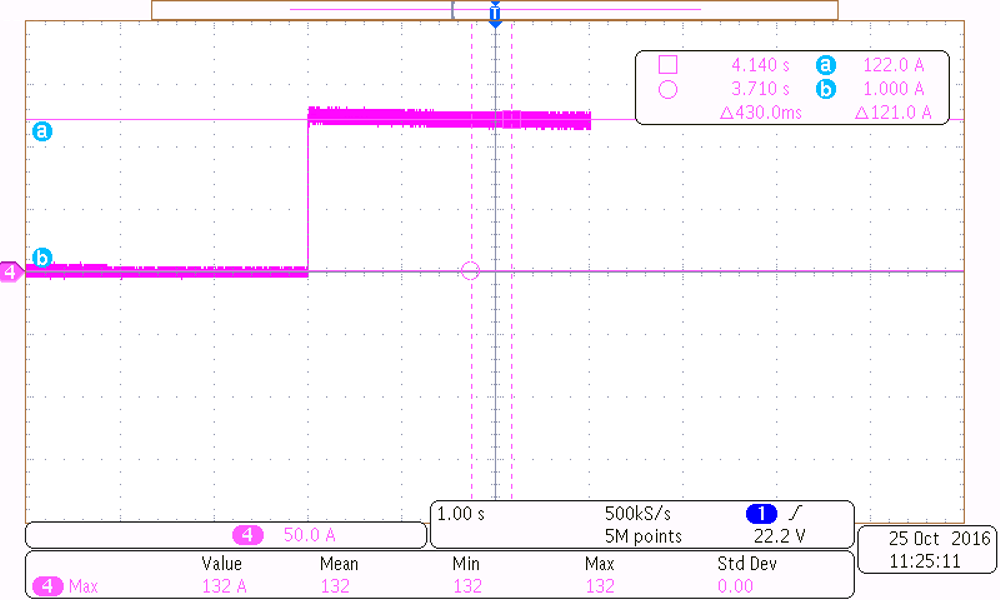

Figure 53 shows the winding current of 120 A when the motor is stalled for 3 seconds. Figure 54 shows the thermal image of the board after 3 seconds.

Figure 53. 120-A Peak Current in Motor Winding During Motor Stall

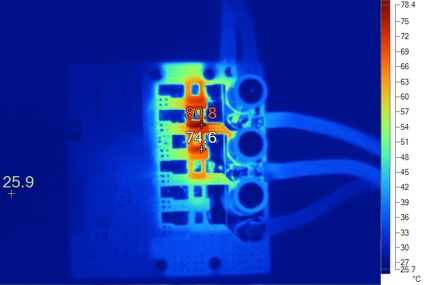

Figure 53. 120-A Peak Current in Motor Winding During Motor Stall  Figure 54. Thermal Image of Board After 3 Seconds With 120-A Peak Current in Motor Winding

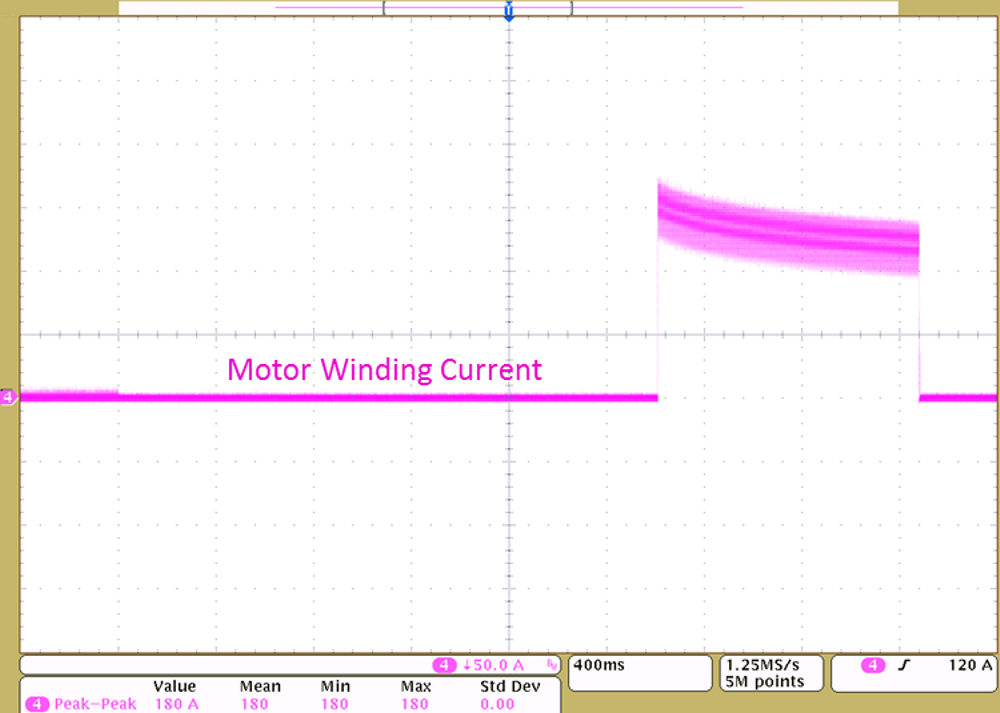

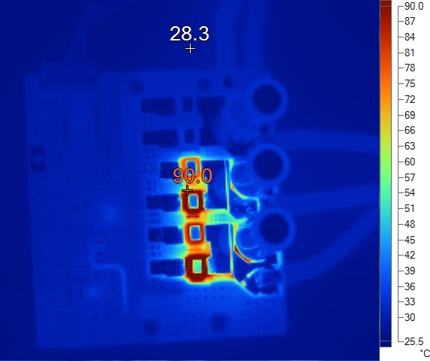

Figure 54. Thermal Image of Board After 3 Seconds With 120-A Peak Current in Motor Winding Figure 55 shows the peak winding current of 180 A when the motor is stalled for more than 1 second. The average motor current is approximately 160 A for this duration. Figure 56 shows the thermal image of the board after 1 second.

The high peak current capability ensures that in power tool applications, the power stage aids the motor to deliver high peak torque. If the stall current continues to be high, over temperature or blocked rotor protection will act to shut off the system.

Figure 55. 160-A Peak Current in Motor Winding During Motor Stall

Figure 55. 160-A Peak Current in Motor Winding During Motor Stall  Figure 56. Thermal Image of Board After 1 Second With 160-A Peak Current in Motor Winding

Figure 56. Thermal Image of Board After 1 Second With 160-A Peak Current in Motor Winding