TIDUCL0 January 2017

- 1 Description

- 2 Resources

- 3 Features

- 4 Applications

- 5 Design Images

- 6 System Overview

-

7 System Design Theory

- 7.1 Power Stage Design—Battery Power Input to the Board

- 7.2 Power Stage Design—Three-Phase Inverter

- 7.3 Power Stage Design—DRV8323 Gate Driver

- 7.4 Power Stage Design—18-V to 3.3-V DC-DC Converter

- 7.5 Power Stage Design —Microcontroller MSP430

- 7.6 Power Stage Design—Hall Sensor Interface

- 7.7 Temperature Sensing

- 7.8 Power Stage Design—External Interface Options and Indications

- 8 Getting Started Hardware and Software

- 9 Testing and Results

- 10Design Files

- 11Software Files

- 12Related Documentation

- 13Terminology

- 14About the Author

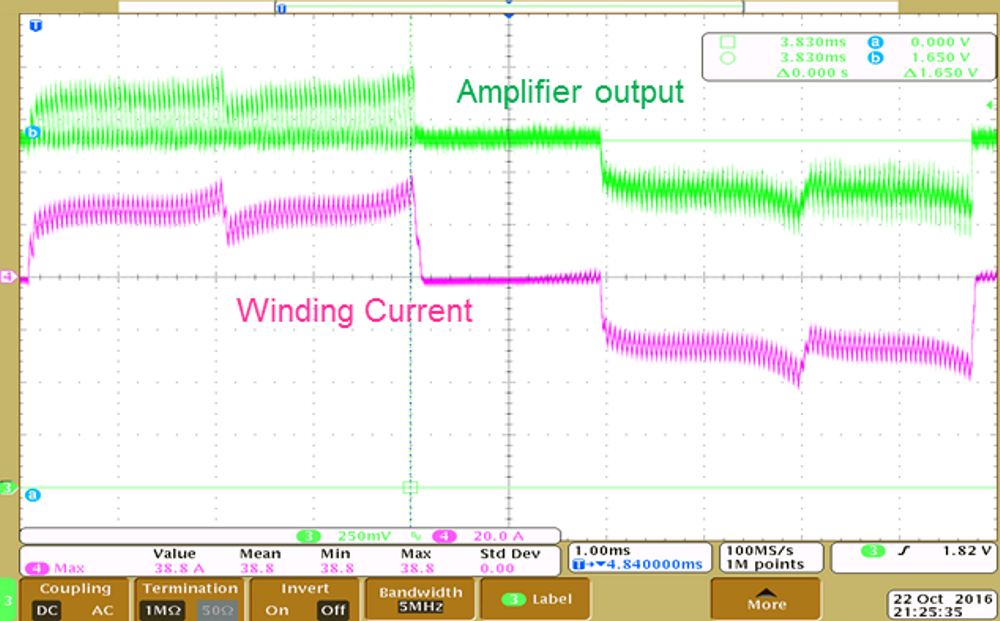

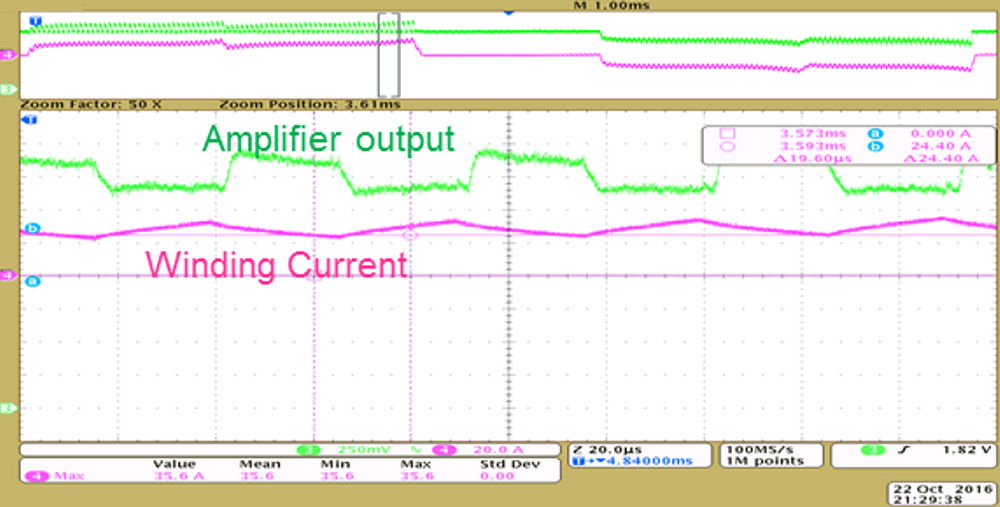

9.2.5 Inverter Current Sensing by VDS Monitoring

The inverter leg current sensing is done by monitoring the VDS of the low side MOSFETs. Table 13 gives the theoretical and actual amplifier output at a positive and negative current. The board temperature is approximately 30°C. The percentage error is calculated without offset or temperature calibration. The equivalent RDS_ON of 0.5 mΩ (two FETs in parallel) is taken for theoretical amplifier output calculation. Figure 42 to Figure 44 show the winding current and amplifier output waveform.

Table 13. Theoretical and Actual Amplifier Output at Positive and Negative Current

| WINDING CURRENT (A) | AMPLIFIER OUTPUT (V) | THEORETICAL AMPLIFIER OUTPUT | % ERROR |

|---|---|---|---|

| 24.4 | 1.86 | 1.894 | –1.79 |

| -22.0 | 1.42 | 1.430 | –0.70 |

Figure 42. Current Sense Amplifier Output With Winding Current

Figure 42. Current Sense Amplifier Output With Winding Current  Figure 43. Current Sense Amplifier Output at Positive Winding Current

Figure 43. Current Sense Amplifier Output at Positive Winding Current  Figure 44. Current Sense Amplifier Output at Negative Winding Current

Figure 44. Current Sense Amplifier Output at Negative Winding Current