SLAU857A May 2021 – July 2021 MSP430FR2476 , MSP430FR2512 , MSP430FR2522 , MSP430FR2532 , MSP430FR2533 , MSP430FR2632 , MSP430FR2633 , MSP430FR2672 , MSP430FR2673 , MSP430FR2675 , MSP430FR2676

5.4.1 Parameter Adjustment Logic and Method

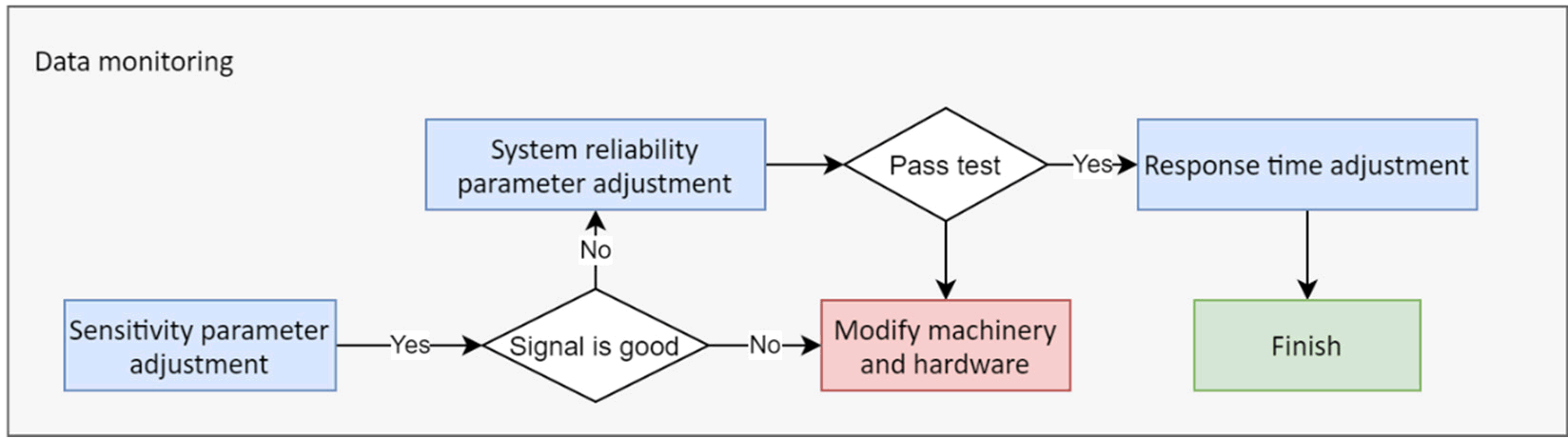

The steps involved in tuning can be roughly divided into four parts: Data monitoring, sensitivity parameters adjustment, system reliability adjustment, response speed and power consumption adjustment. The overall idea is to first adjust the sensitivity, then adjust the reliability of the touch, and finally adjust the response time and power consumption. Remember to use the data monitoring function to evaluate the effect of parameter adjustment during the entire parameter adjustment process.

The logic block diagram of parameter adjustment is shown in Figure 5-11. Each parameter adjustment step often needs to be repeated. It should be noted that the difficulty of the entire parameter tuning has a great relationship with the initial mechanical and hardware design. A good mechanical and hardware design mean that the noise of the touch signal is stronger, and the system reliability parameter adjustment is simpler.

The two button nodes in the entire development process are: whether the signal change generated by the touch is higher than the minimum threshold, whether the system can pass the reliability test. The former characterizes the amount of signal generated by the touch. If the amount of signal is too small, the system may be affected by noise and cause false touches. The latter characterizes whether the system can work normally under certain conditions. Failure to meet any of the above conditions means that the machinery and hardware need to be modified.

Figure 5-11 Logic of Parameter Adjustment

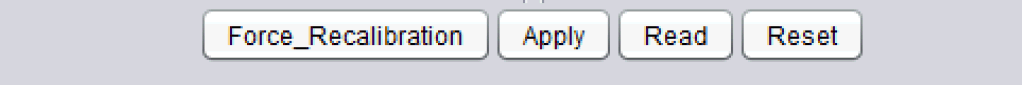

Figure 5-11 Logic of Parameter AdjustmentBefore adjusting the parameters, first click Communications->Connect on the main GUI interface to connect the MCU to the GUI, and then adjust the relevant parameters according to the following subsections. In the process of online parameter adjustment, the following buttons in the sensor widget are used to control parameter update and reset, as shown in Figure 5-12. The corresponding functions are shown in Table 5-4. If there is no response from the GUI, remove and restore power and confirm that the HID Bridge UART/I2C is connected correctly.

Figure 5-12 Online Tuning Button

Figure 5-12 Online Tuning Button| Number | Button | Description |

|---|---|---|

| 1 | Force Recalibration | Mandatory system calibration, used when the button function is not normal. |

| 2 | Apply | Transfer the parameters on the GUI to the MCU. |

| 3 | Read | Read the current relevant parameters in the MCU. |

| 4 | Reset | Reset the touch parameters in the GUI and MCU to the initial configuration values of the GUI. |