SLYA048B March 2020 – June 2021 FDC1004 , FDC1004-Q1 , FDC2112 , FDC2112-Q1 , FDC2114 , FDC2114-Q1 , FDC2212 , FDC2212-Q1 , FDC2214 , FDC2214-Q1 , LDC0851 , LDC1001 , LDC1041 , LDC1051 , LDC1101 , LDC1312 , LDC1312-Q1 , LDC1314 , LDC1314-Q1 , LDC1612 , LDC1612-Q1 , LDC1614 , LDC1614-Q1 , LDC2112 , LDC2114 , LDC3114 , LDC3114-Q1

- Trademarks

- 1Inductive and Capacitive Theory of Operation

- 2FDC: Capacitive Level Sensing

- 3LDC: Inductive Touch Buttons

- 4LDC: Incremental Encoder and Event Counting

- 5LDC: Metal Proximity Sensor

- 6Revision History

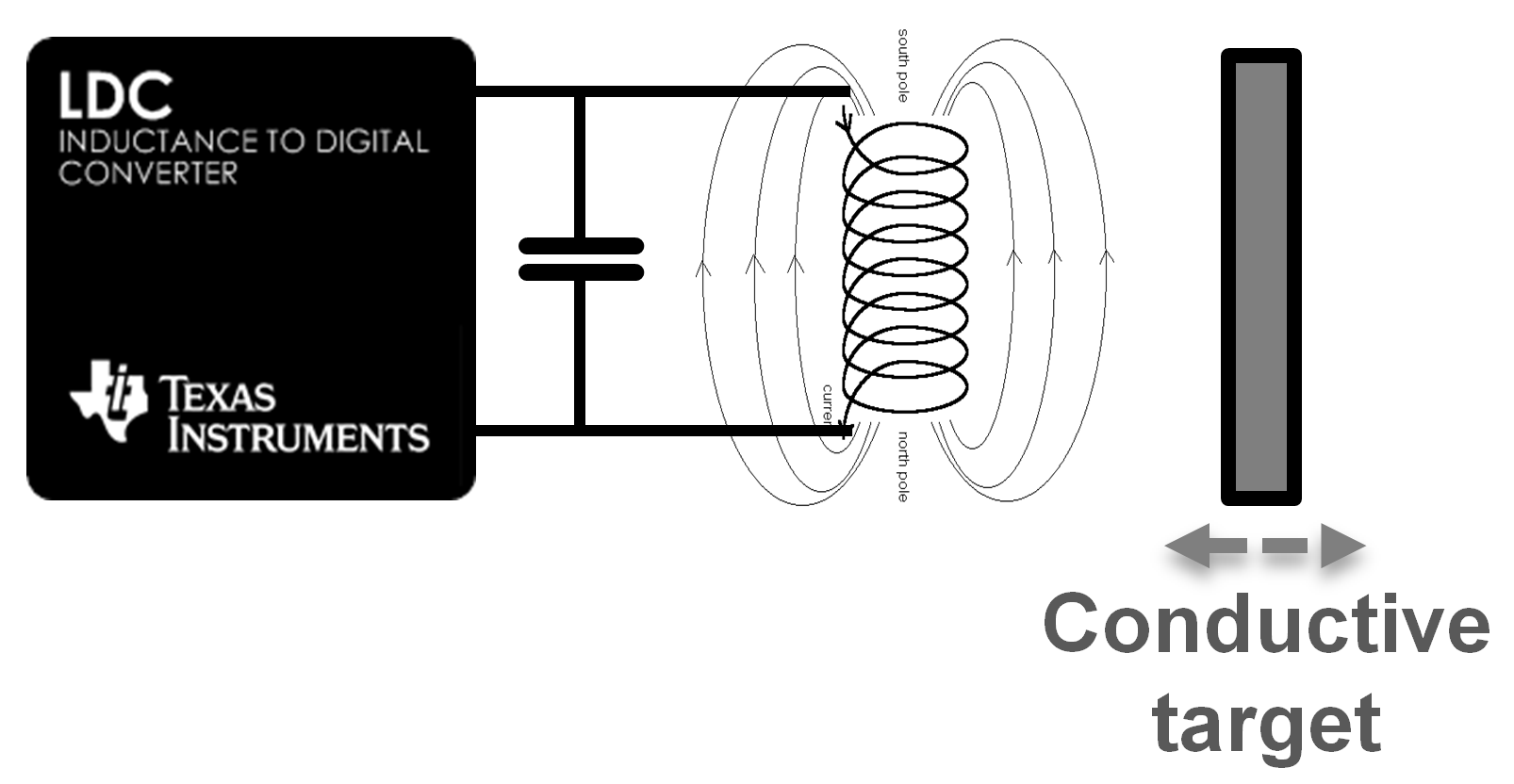

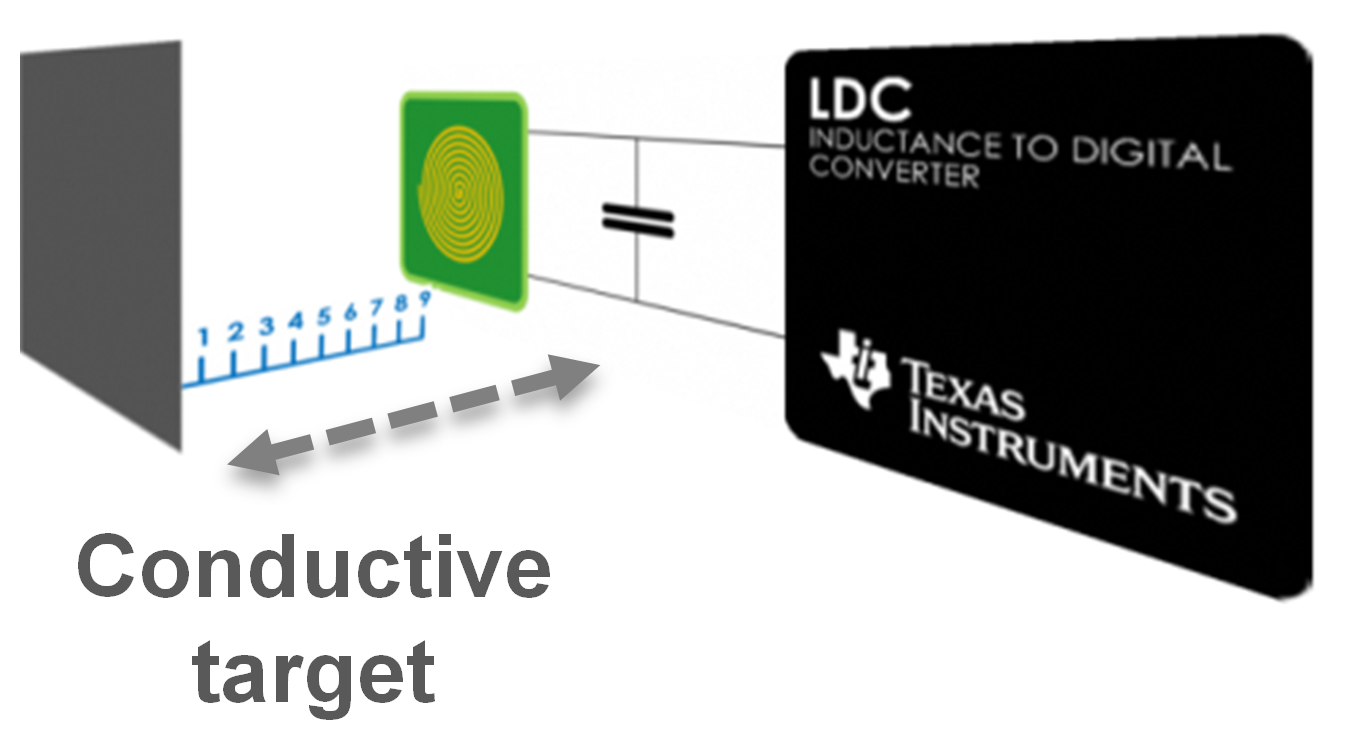

5 LDC: Metal Proximity Sensor

Power tools and other industrial equipment must often detect metal in certain applications (like a pipe finder, for example). Inductive-based technologies are ideal for metal detection as an inductance-to-digital converter can sense the presence or proximity of a metal. Inductive sensors can also detect the level of compression of a spring and can measure the speed and position of a rotational system (like gear tooth counting, for example).

Common applications include: metal detection in power tools and pipe finders, along with spring compression detection.

Figure 5-1 Wire Wound Sensor Coil

Figure 5-1 Wire Wound Sensor Coil Figure 5-2 PCB Sensor Coil

Figure 5-2 PCB Sensor Coil