SPRACX7 April 2021 AWR1243 , AWR1443 , AWR1642 , AWR1843 , AWR1843AOP , AWR2243 , AWR2944 , AWR6843 , AWR6843AOP , IWR1443 , IWR1642 , IWR1843 , IWR6443 , IWR6843 , IWR6843AOP

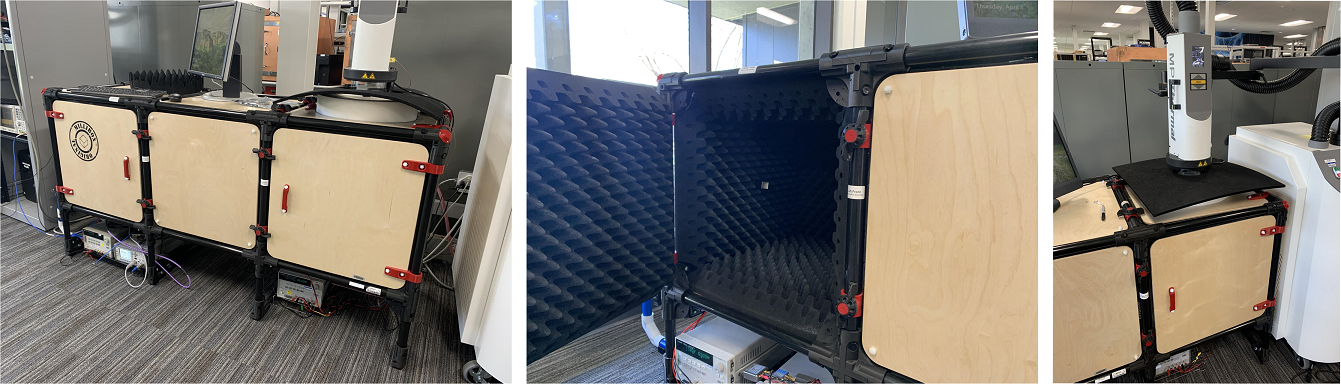

2.1.1 Low Cost Bench Top Anechoic Chamber

One option for a low-cost production testing environment is to build a custom bench top anechoic chamber with mmWave absorber materials. The chamber should be lined with a mmWave absorber material that provides sufficient absorption for the desired frequency of operation. Milliwave Silicon Solutions produces pre-built chambers, called a MilliBox, that are designed to provide -50 dB absorption at 60 GHz and 77 GHz at nominal incidence. These chambers are modular and can be configured to meet various different far field distance requirements and can be as small as 4’ x 3’ x 2’ to fit in space constrained environments or on a lab bench top. The chamber can be fit with a gimbal to rotate the DUT ±180 degrees along the horizontal and vertical axis. The gimbal can be automated using the test PC over a USB serial interface. A horn post can be mounted on the opposite side of the chamber to provide a location to mount a horn antenna or a corner reflector target.

Figure 2-3 Example Bench Top Anechoic Chamber

Figure 2-3 Example Bench Top Anechoic Chamber