SLOA289B May 2020 – September 2021 66AK2H06 , 66AK2H12 , 66AK2H14 , ADS8588H , AMC3301 , ISO224 , ISO7740 , ISO7741 , ISO7742 , LMZ30604 , SN65LVDS047 , SN65LVDS048A , UCC12040 , UCC12050

- Trademarks

- 1HVDC Power Transmission Overview and Architecture

- 2HVDC Transmission System (HVDC station)

- 3HVDC transmission station - Control and Protection (C and P)

- 4HVDC Transmission Control and Protection – System Level Block Diagram

- 5TI Solutions for HVDC Transmission Station Control and Protection

- 6Summary

- 7TI Reference Designs

- 8Additional References

- 9Revision History

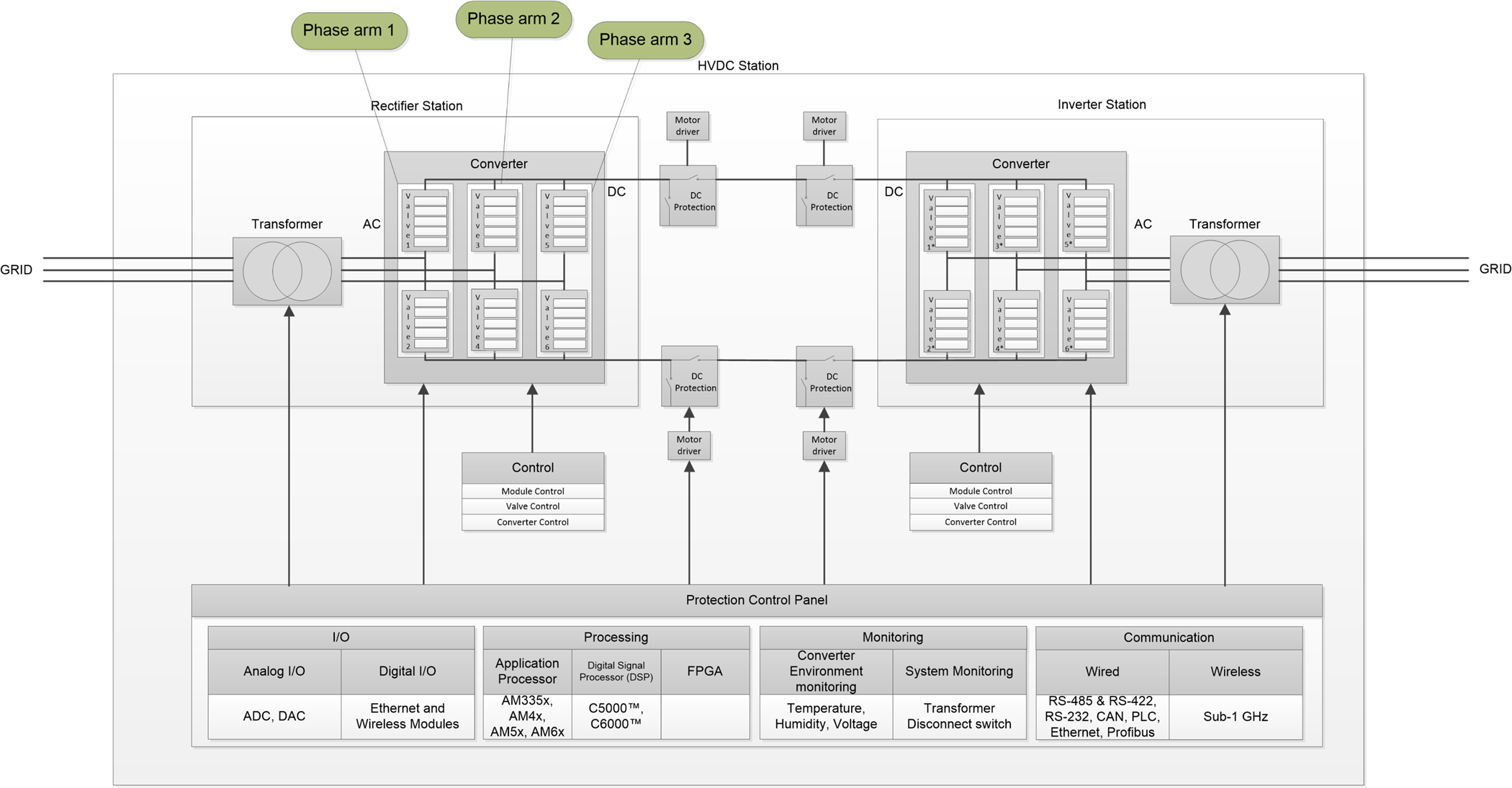

3 HVDC transmission station - Control and Protection (C and P)

Each HVDC converter station is equipped with a control and protection system designed to operate satisfactorily under normal as well as abnormal conditions. The control system is designed to be self-protecting, efficient, has stable operation and provides maximum power control flexibility without compromising the system safety. HVDC C and P additionally ensures there are no harmful interactions between the HVDC transmission system and the AC network that may adversely affect the HVDC converter or AC network protection system or users of the transmission system. The control and protection system for both the converters (rectifier and inverter) is designed to be identical as much as possible.

The C and P system is designed to have full redundancy for all the vital systems and includes measuring, processing, switching, indicating and communicating systems. Converter control achieves the desired power transmission and AC bus voltage magnitude coupled with automatic switching of filters, capacitor and reactor banks. The open/close commands to the high voltage devices are interlocked in the controls to prevent out of-step operation of breakers, disconnectors and ground switches. Also interlocks to prevent forbidden system or switchyard configurations are installed. Interlocking to prevent personnel access to the valve hall and filter, areas that are not walk through, is provided by means of interlocks controlled by the Station Controls. Figure 3-1 provides an overview of the control and protections used in an HVDC station.

Figure 3-1 HVDC Transmission Station – Control and Protection

Figure 3-1 HVDC Transmission Station – Control and Protection