SLVAFF1 January 2023 DRV8452 , DRV8462

PRODUCTION DATA

- Abstract

- Trademarks

- 1Power Efficiency of Stepper Motor Drivers

-

2Auto-Torque

- 2.1 Auto-Torque: Learning Principle

- 2.2 Current Control

- 2.3 PD Control Loop

- 2.4

Impact of Auto-Torque Tuning

Parameters

- 2.4.1 Impact of Learning Parameters on Load Transient Response

- 2.4.2 Impact of ATQ_UL, ATQ_LL Hysteresis

- 2.4.3 Impact of Load Profile on Power Saving

- 2.4.4 Adaptive ATQ_UL, ATQ_LL

- 2.4.5 PD Parameter Dependency Curves

- 2.4.6 ATQ_CNT at Different Motor Speeds

- 2.4.7 ATQ_CNT at Different Supply Voltages

- 2.4.8 Motor Temperature Estimation

- 2.5 Efficiency Improvement With Auto-Torque

- 3Case Studies

- 4Summary

- 5References

2.4.5.2 Dependency on KD and ATQ_D_THR

- Increasing the value of KD will cause the control system to react more strongly to changes in the error term and will increase the speed of the overall control system response, as shown by Figure 2-22 and Figure 2-23.

- It is recommended to use small value of KD, because the derivative response is highly sensitive to noise.

- When non-zero values of KD is selected, to improve noise immunity of the system, a high value of ATQ_D_THR should be used.

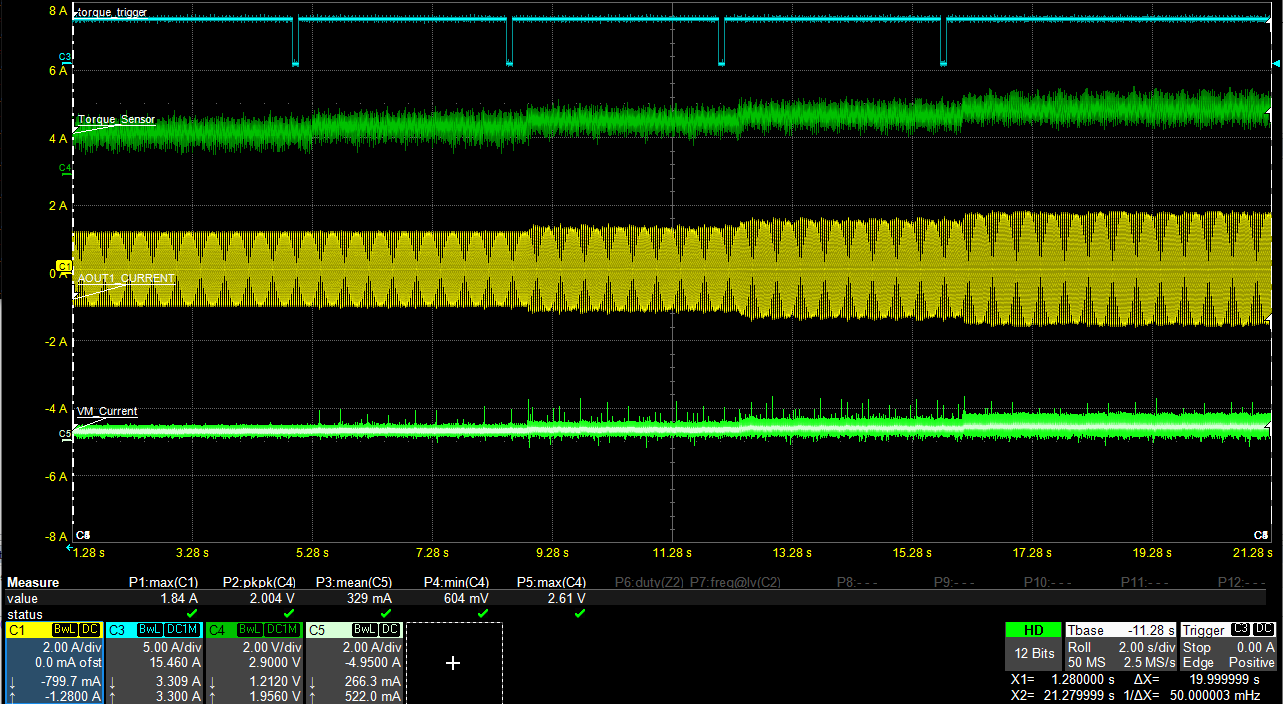

Figure 2-22 KD = 0, Load

Torque Changed From 0.3 Nm to 0.57 Nm

Figure 2-22 KD = 0, Load

Torque Changed From 0.3 Nm to 0.57 Nm Figure 2-23 KD = 5,

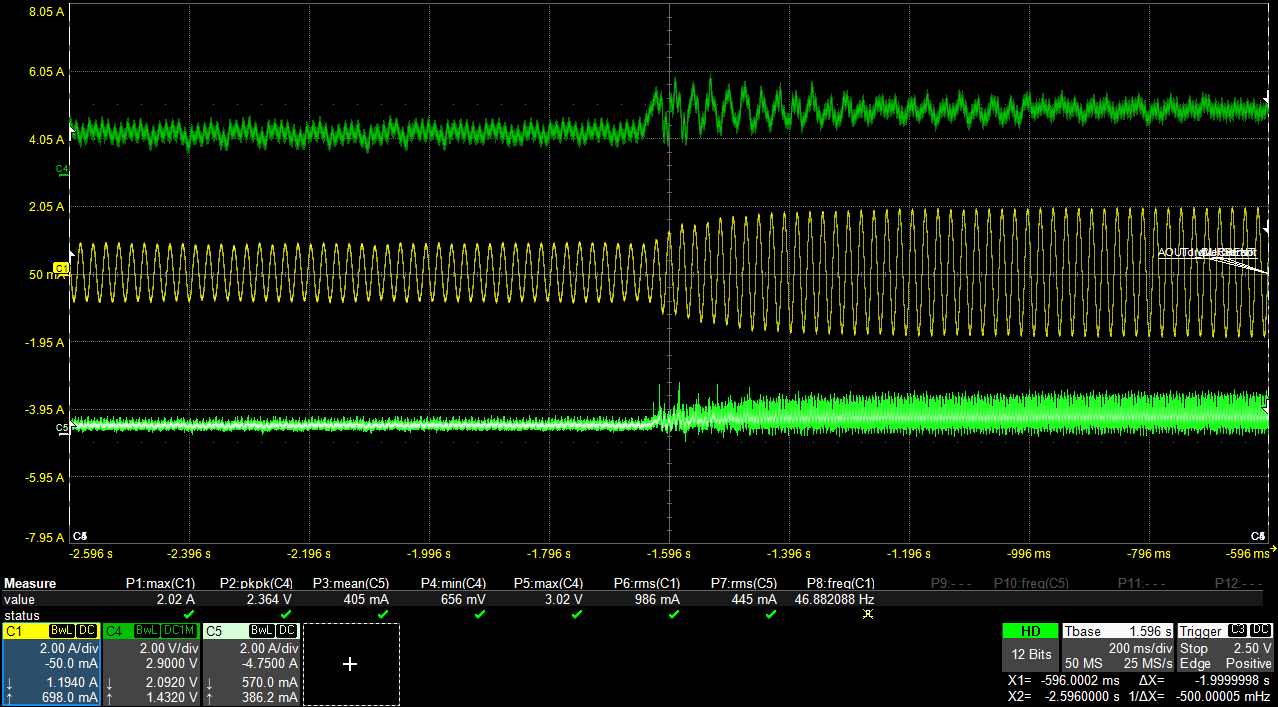

ATQ_D_THR = 30, Load Torque Changed From 0.3 Nm to 0.57 Nm

Figure 2-23 KD = 5,

ATQ_D_THR = 30, Load Torque Changed From 0.3 Nm to 0.57 Nm