TIDUEY6 April 2021

- Description

- Resources

- Features

- Applications

- 5

- 1System Description

- 2System Overview

-

3Hardware, Software, Testing Requirements, and Test Results

- 3.1

Hardware Requirements

- 3.1.1

Hardware Overview

- 3.1.1.1

Control Module

- 3.1.1.1.1

Control Mother Board

- 3.1.1.1.1.1 Inverter Safing - UCC5870 ASC and Fault Control

- 3.1.1.1.1.2 DC-DC Safing

- 3.1.1.1.1.3 DC-DC Converter Secondary PWM Selection

- 3.1.1.1.1.4 Blower Fan Control

- 3.1.1.1.1.5 Voltage Monitor

- 3.1.1.1.1.6 Resolver Interface Control

- 3.1.1.1.1.7 Test Points on Control Module

- 3.1.1.1.1.8 General Purpose Ports

- 3.1.1.1.1.9 Connectors and Headers on Control Mother Board

- 3.1.1.1.2 Power Supplies

- 3.1.1.1.3 TCAN4550 module

- 3.1.1.1.4 Dual TCAN Module

- 3.1.1.1.5 Analog Back End Module

- 3.1.1.1.6 Resolver Analog Front End Module

- 3.1.1.1.1

Control Mother Board

- 3.1.1.2 Inverter Module

- 3.1.1.3 DC-DC Bidirectional Converter Module

- 3.1.1.1

Control Module

- 3.1.1

Hardware Overview

- 3.2 Resource Mapping

- 3.3 Test Setup

- 3.4 Test Results

- 3.1

Hardware Requirements

- 4General Texas Instruments High Voltage Evaluation (TI HV EVM) User Safety Guidelines

- 5Design and Documentation Support

- 6About the Author

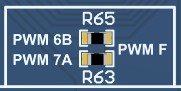

3.1.1.1.1.3 DC-DC Converter Secondary PWM Selection

DC-DC converter requires 4 PWMs on the

primary side and 2 on the secondary. The first PWM for secondary side is taken from

EPWM6A. For flexibility sake, the second PWM is taken either from EPWM6B or EPWM7A. One

of them will become redundant, but it can give some design options for experimenting

during implementation. The related section on the control mother board is shown in Figure 3-6.

Figure 3-6 Secondary PWM Source

Selection

Figure 3-6 Secondary PWM Source

Selection

Figure 3-6 Secondary PWM Source

Selection

Figure 3-6 Secondary PWM Source

SelectionA 0E resistor on R65 will select EPWM6B as the source for 6th PWM (PWM F), whereas a 0E resistor on R63 will select EPWM7A for the same.

CAUTION:

It is not advisable to mount both R63 and R65 together, and better be kept mutually exclusive to avoid malfunction or electrical damage to the pins if the other pin were to be used accidentally.

Tip: The unused GPIO

pin between EPWM6B and EPWM7A could be used as a general purpose flag if required

and could be monitored on the open terminal side of R63 or R65.