SLVSGK4A November 2021 – June 2022 TPS22953-Q1 , TPS22954-Q1

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- Recommended Operating Conditions

- 7.3 Thermal Information

- 7.4 Electrical Characteristics

- 7.5 Electrical Characteristics – VBIAS = 5 V

- 7.6 Electrical Characteristics – VBIAS = 3.3 V

- 7.7 Electrical Characteristics – VBIAS = 2.5 V

- 7.8 Switching Characteristics – CT = 1000 pF

- 7.9 Switching Characteristics – CT = 0 pF

- 7.10 Typical DC Characteristics

- 7.11 Typical Switching Characteristics

- 8 Parameter Measurement Information

-

9 Detailed Description

- 9.1 Overview

- 9.2 Functional Block Diagram

- 9.3

Feature Description

- 9.3.1 On and Off Control (EN Pin)

- 9.3.2 Voltage Monitoring (SNS Pin)

- 9.3.3 Power Good (PG Pin)

- 9.3.4 Supervisor Fault Detection and Automatic Restart

- 9.3.5 Manual Restart

- 9.3.6 Thermal Shutdown

- 9.3.7 Reverse Current Blocking (TPS22953-Q1 Only)

- 9.3.8 Quick Output Discharge (QOD) (TPS22954-Q1 Only)

- 9.3.9 VIN and VBIAS Voltage Range

- 9.3.10 Adjustable Rise Time (CT Pin)

- 9.3.11 Power Sequencing

- 9.4 Device Functional Modes

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DQC|10

Thermal pad, mechanical data (Package|Pins)

- DQC|10

Orderable Information

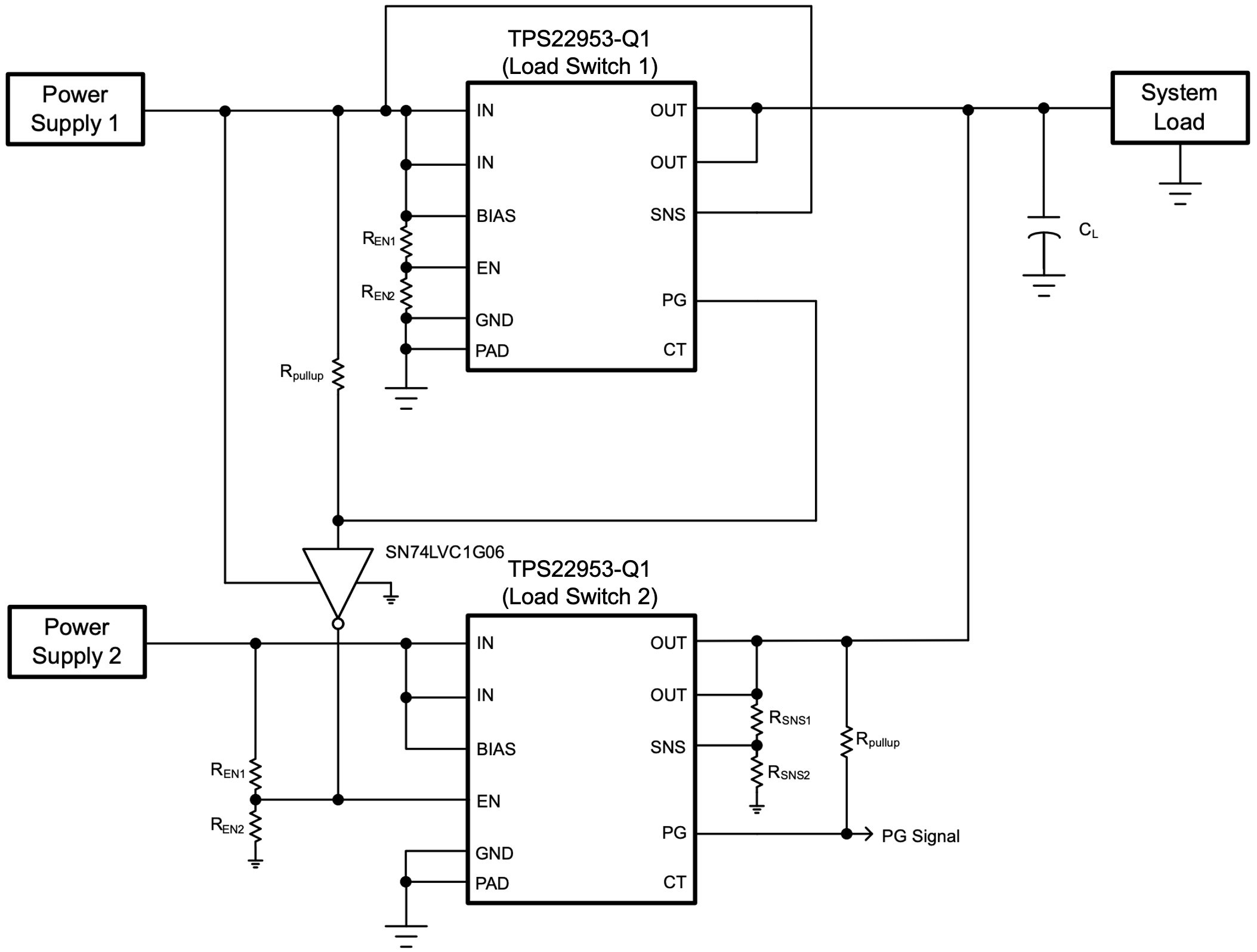

10.1.6 Break-Before-Make Power MUX (TPS22953-Q1 Only)

The reverse current blocking feature of the TPS22953-Q1 makes it suitable for power multiplexing (MUXing) between two power supplies with different voltages. The SNS and PG pin can be configured to implement break-before-make logic. The circuit in Figure 10-4 shows how the detection of power supply 1 can be used to disable the load switch for power supply 2. By tying the SNS of Load Switch 1 directly to the input, its PG pin is pulled up as soon as the device is enabled.

Figure 10-4 Break-Before-Make Power MUX Schematic

Figure 10-4 Break-Before-Make Power MUX SchematicThe break-before-make logic ensures that power supply 2 is completely disconnected before power supply 1 is connected. This approach provides very robust reverse current blocking. However, in most cases, this aproach also results in a dip in the output voltage when switching between supplies.

The amount of voltage dip depends on the loading, the output capacitance, and the turn-on delay of the load switch. In this application, leaving the CT pin open results in the shortest turn-on delay and minimizes the output voltage dip.

Table 10-1 summarizes the logic of the PG Signal for Figure 10-4.

| PG Signal | Indication |

|---|---|

| H | Power supply 1 not present. System powered from power supply 2. |

| L | Power supply 1 present. System powered from power supply 1. |