SPRAD20 March 2022 AM2631 , AM2631-Q1 , AM2632 , AM2632-Q1 , AM2634 , AM2634-Q1

- Trademarks

- 1Introduction

-

2A Step-by-Step Guide to Running a Traction

Inverter

- 2.1 Create Real Time Debug Interface

- 2.2 Configure Control Peripheral and ADC Interrupt With Sysconfig

- 2.3 Configure Gate Driver Interface With MSPI

- 2.4 Get Samples From ADC and Read Samples Via CCS

- 2.5 Generate Space Vector PWM and Drive Motor in Open Loop

- 2.6 Close Current Loop With Mock Speed

- 2.7 Add Software Resolver to Digital Converter

- 2.8 Close Speed Loop With Rotor Speed

- 3A Brief Guide to Code Migration

- 4Summary

- 5References

2.5.3 Power Up Inverter and Spin Motor in Open Loop

When the inverter is powered up, it is ready to spin a motor in open loop. It is recommended to start with low speed. The global variable SpdRef in per unit can be set around 0.01. There are couple flags controlling the execution of example program as listed. "runMotor" is the gate for "gTFlag_MockTheta" and "gTFlag_SpdDemo". Speed command will not be sent if "runMotor" is "FALSE". "gTFlag_MockTheta" is to use mock angle and speed for open loop and closed current loop. "gTFlag_SpdDemo" is to give speed command for demonstration of closed speed loop. "gTFlag_MockTheta" and "gTFlag_SpdDemo" should not be "TRUE" at the same time. The motor must be stopped with "runMotor" before switching between "gTFlag_MockTheta" and "gTFlag_SpdDemo". When "gTFlag_MockVdq" is "TRUE", Vd and Vq from program prior to SVPWM generation will be overwritten by manual inputs from expression window. When "gTFlag_MockId" or "gTFlag_MockIq" is "TRUE", current values at the input of current loop controller will be replaced by manual inputs from expression window.

- runMotor

- gTFlag_MockTheta

- gTFlag_MockVdq

- gTFlag_MockId

- gTFlag_MockIq

- gTFlag_SpdDemo

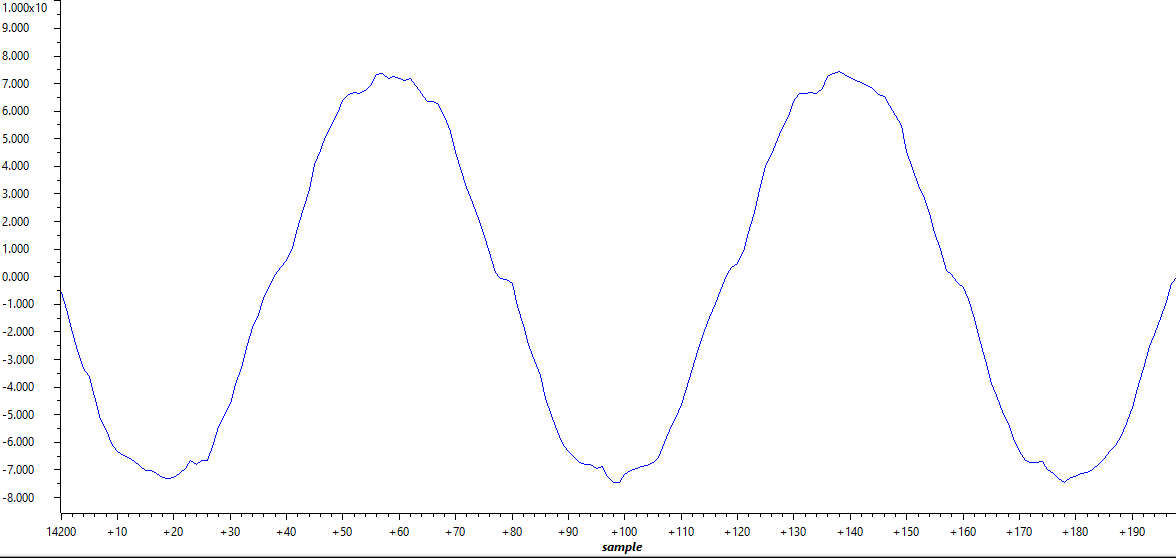

In this part, after setting "gTFlag_MockTheta" and "gTFlag_MockVdq" to "TRUE", "runMotor" can be changed to "TRUE". With properly selected "SpdRef", "VdTesting", and "VqTesting". It is worth attention that Vd and Vq are real value other than per unit value here. Phase A current can be read like Section 2.4.3. It is plotted in Figure 2-36. With some low frequency AC current, the motor should start spinning. If not, it is recommended to check motor, inverter, and control card. Inverter hardware details can be found at TIDM-02009. Control card details should be located in user guide.

Figure 2-36 Phase A Current Open

Loop

Figure 2-36 Phase A Current Open

Loop