Powering control modules with 12-V board nets

A traditional 12-V board net has a wide voltage range, as prescribed in the International Organization for Standardization (ISO) 7637-2 and ISO 16750-2 standards. While these requirements are unlikely to change for

combustion engine-based cars, the use of 12 V in hybrid and electric vehicles could result in a lower maximum voltage, especially if the 12-V bus has no alternator – that is, if all the power needed on the 12-V board net is derived from the

high-efficiency DC/DC converter that is used to step down from high voltage to 12 V. In this case, lower-input voltage regulators could be used to implement power-management solutions in ECUs.

Designers have the flexibility to solve different technical challenges in control modules powered by 12-V power board net with a range of automotive-qualified products such as power management, amplifiers, transceivers, motor drivers and smart power switches.

Addressing challenges in 48-V board nets

The 48-V board net is typically used to power loads that require higher power. The specific loads that are powered by 48 V depends on the vehicle type. Regardless of the type of module, control modules connected to

the 48 V board net will need power management devices that are efficient, have high power density and are able to withstand operating voltage requirements specified in ISO 21780. The modules also need functional isolation if the ECU is also

connected to a 12-V board net. Efficient multiphase 48-V gate drivers with functional safety to drive the 48-V actuators such as the belt starter generator or HVAC AC compressor module. The need for functional safety drives the need for

additional diagnostic circuits such as load-current sensing. The deployment of a 48-V power board net would also require efficient, accurate state-of-charge and state-of-health management in 48-V battery-management systems.

To boost efficiency, increase power density and achieve functional safety in 48 V board net systems, designers can use products such as buck regulators, three-phase gate drivers and battery management systems along with the broad portfolio of current and voltage sense amplifiers.

Maximizing the high-voltage board net

Electric vehicles have battery systems that generate much higher voltage. High power loads such as the traction inverter and the HVAC AC compressor module are directly powered from the high voltage board net. This

implies that the power stages that are used to actuate these high voltage loads need to withstand high operating voltages and require high common-mode transient immunity (CMTI). Furthermore, compact solution implementations need high power

density gate drivers and power stages. The use of multiple power board nets also requires isolation within the control module between the low- and high-voltage domains to ensure proper operation. The use of high voltage could require

designs that not only meet electrical safety requirements but also satisfy functional-safety-requirements. The latter requirements necessitate the implementation of diagnostic features, resulting in additional current-, voltage- and

temperature-sensing solution in these systems. Moreover, efficient high voltage battery-management systems that have accurate state-of-charge and state-of-health management and maintain better cell uniformity are also needed.

High voltage gate drivers, battery management systems, power and signal

isolators, and high-speed amplifiers are among a broad portfolio of products that designers can use to

optimize and meet the challenges of efficiency, power density, functional safety and reliability in high voltage control modules.

Designing for low to high voltage

Automotive design engineers can choose from a wide range of analog and embedded semiconductor devices for 12-V, 48-V and high voltage board nets. These products offer the flexibility to design vehicle architectures

with efficient ECUs and help achieve your power density, reliability and functional safety design goals.

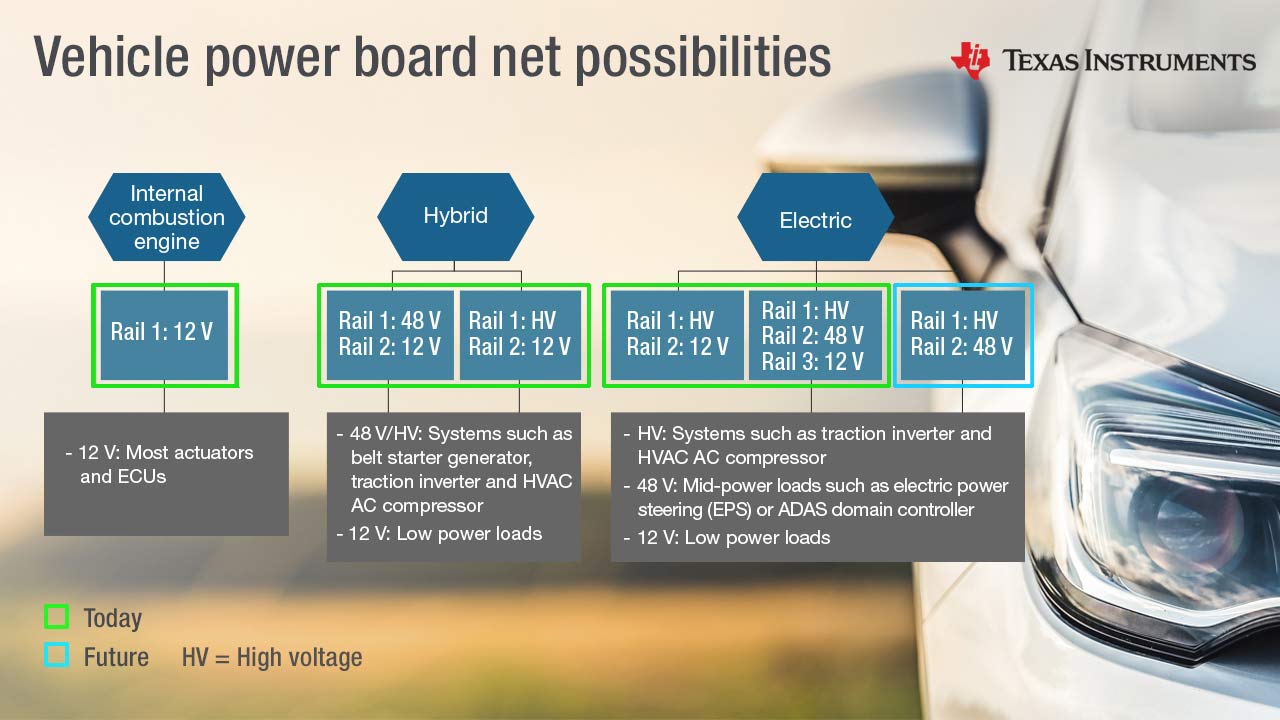

Figure 1 Voltage board nets in

vehicles

Figure 1 Voltage board nets in

vehicles