SPRACN0F October 2021 – March 2023 F29H850TU , F29H859TU-Q1 , TMS320F280021 , TMS320F280021-Q1 , TMS320F280023 , TMS320F280023-Q1 , TMS320F280023C , TMS320F280025 , TMS320F280025-Q1 , TMS320F280025C , TMS320F280025C-Q1 , TMS320F280033 , TMS320F280034 , TMS320F280034-Q1 , TMS320F280036-Q1 , TMS320F280036C-Q1 , TMS320F280037 , TMS320F280037-Q1 , TMS320F280037C , TMS320F280037C-Q1 , TMS320F280038-Q1 , TMS320F280038C-Q1 , TMS320F280039 , TMS320F280039-Q1 , TMS320F280039C , TMS320F280039C-Q1 , TMS320F280040-Q1 , TMS320F280040C-Q1 , TMS320F280041 , TMS320F280041-Q1 , TMS320F280041C , TMS320F280041C-Q1 , TMS320F280045 , TMS320F280048-Q1 , TMS320F280048C-Q1 , TMS320F280049 , TMS320F280049-Q1 , TMS320F280049C , TMS320F280049C-Q1 , TMS320F28374D , TMS320F28374S , TMS320F28375D , TMS320F28375S , TMS320F28375S-Q1 , TMS320F28376D , TMS320F28376S , TMS320F28377S , TMS320F28377S-Q1 , TMS320F28378D , TMS320F28378S , TMS320F28379D , TMS320F28379D-Q1 , TMS320F28379S , TMS320F28384D , TMS320F28384S , TMS320F28386D , TMS320F28386S , TMS320F28388D , TMS320F28388S , TMS320F28P650DH , TMS320F28P650DK , TMS320F28P650SH , TMS320F28P650SK , TMS320F28P659DH-Q1 , TMS320F28P659DK-Q1 , TMS320F28P659SH-Q1

- The Essential Guide for Developing With C2000™ Real-Time Microcontrollers

- Trademarks

- 1C2000 and Real-Time Control

-

2Sensing Key Technologies

- 2.1 Accurate Digital Domain Representation of Analog Signals

- 2.2 Optimizing Acquisition Time vs Circuit Complexity for Analog Inputs

- 2.3 Hardware Based Monitoring of Dual-Thresholds Using a Single Pin Reference

- 2.4 Resolving Tolerance and Aging Effects During ADC Sampling

- 2.5 Realizing Rotary Sensing Solutions Using C2000 Configurable Logic Block

- 2.6 Smart Sensing Across An Isolation Boundary

- 2.7 Enabling Intra-Period Updates in High Bandwidth Control Topologies

- 2.8 Accurate Monitoring of Real-Time Control System Events Without the Need for Signal Conditioning

-

3Processing Key Technologies

- 3.1 Accelerated Trigonometric Math Functions

- 3.2 Fast Onboard Integer Division

- 3.3 Hardware Support for Double-Precision Floating-Point Operations

- 3.4 Increasing Control Loop Bandwidth With An Independent Processing Unit

- 3.5 Flexible System Interconnect: C2000 X-Bar

- 3.6 Improving Control Performance With Nonlinear PID Control

- 3.7 Understanding Flash Memory Performance In Real-Time Control Applications

- 3.8 Deterministic Program Execution With the C28x DSP Core

- 3.9 Efficient Live Firmware Updates (LFU) and Firmware Over-The-Air (FOTA) updates

-

4Control Key Technologies

- 4.1 Reducing Limit Cycling in Control Systems With C2000 HRPWMs

- 4.2 Shoot Through Prevention for Current Control Topologies With Configurable Deadband

- 4.3 On-Chip Hardware Customization Using the C2000 Configurable Logic Block

- 4.4 Fast Detection of Over and Under Currents and Voltages

- 4.5 Improving System Power Density With High Resolution Phase Control

- 4.6 Safe and Optimized PWM Updates in High-Frequency, Multi-Phase and Variable Frequency Topologies

- 4.7 Solving Event Synchronization Across Multiple Controllers in Decentralized Control Systems

- 5Interface Key Technologies

- 6Safety Key Technologies

- 7References

- 8Revision History

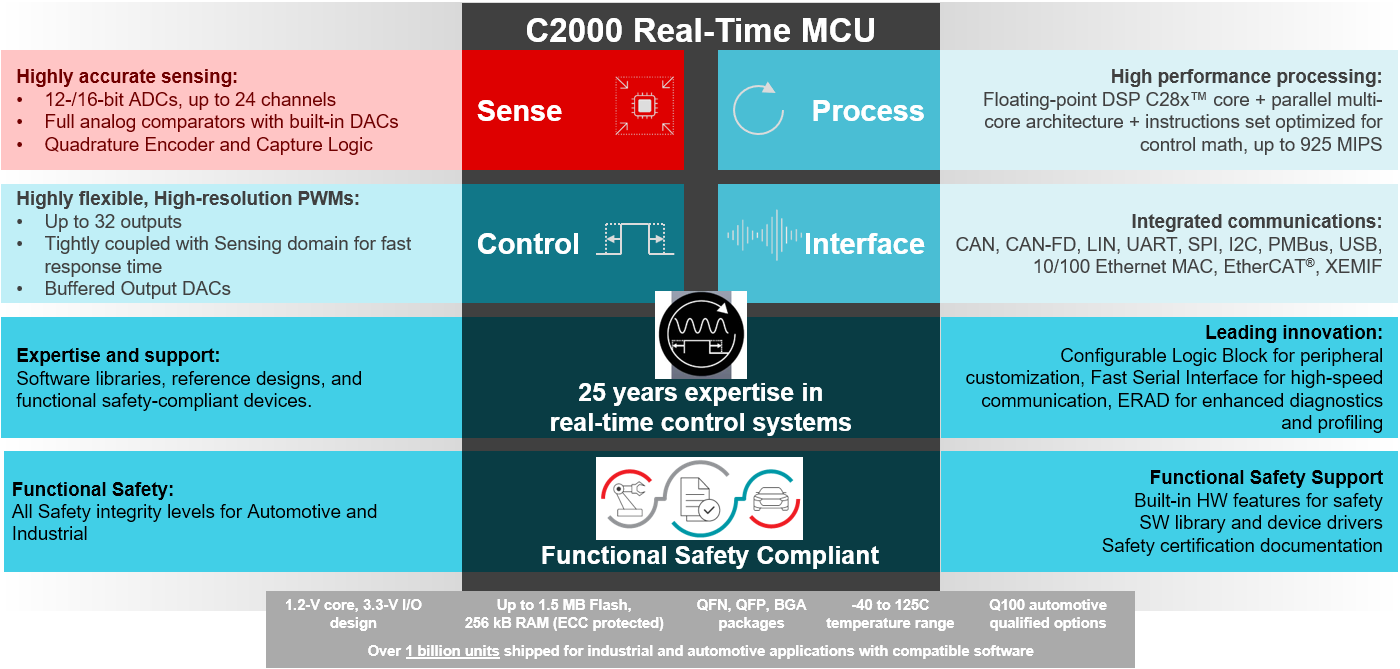

1 C2000 and Real-Time Control

Starting in 1997, Texas Instruments integrated flash memory, an Analog-to-Digital Converter (ADC), a Digital Signal Processor (DSP) , and Pulse Width Modulation (PWM) units on a single device. The first C2000 real-time control MCU was born.

Over more than two decades, this device family grew and now millions of C2000's can be found in numerous applications in industrial and automotive applications like Motor Control, Solar Inverters, Digital Power, Electrical Vehicles and more (see #GUID-A8BC3D2C-5F37-47C8-B571-415A50A586A0). There is one tie that binds all the above applications; their real-time nature and the need for a real-time controller.

A real-time control system is typically composed of four main elements: see #T5843526-2:

- Sensing: or feedback acquisition. The application needs to measure several key parameters (voltage, current, motor speed, temperature) in an accurate manner and at a very precise moment in time.

- Processing: Use the sensing information to apply control algorithms to the incoming data and calculate the next output command.

- Control: The command is applied to the system, typically via a PWM unit driving the power electronics system, for example, the motor turns faster, the current to the solar installed system is reduced, the car is accelerating.

- Interface: The ability of the device to communicate to other external components. While not necessarily involved in the control of the system, communications to other system components also has to co-exist with the main control loop.

Figure 1-2 C2000 Real-Time MCU

Components

Figure 1-2 C2000 Real-Time MCU

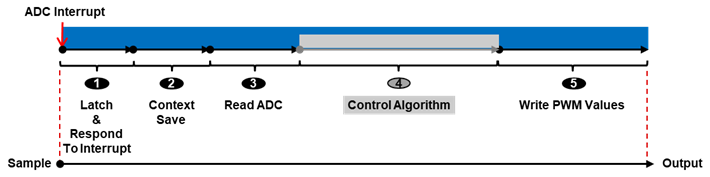

ComponentsThe key to real-time control is to minimize the time between Sensing, Processing and Control: this time is defined as the Real-Time Signal Chain. #GUID-83981EAD-BC90-4152-A06F-A8E411260568 illustrates how the entire process is critical to understand the overall system performance of a real-time controller, vs simply looking at the time it takes the main processing unit to complete the control algorithm (step 4).

Figure 1-3 Real-Time Signal Chain

Components

Figure 1-3 Real-Time Signal Chain

ComponentsMany benchmarks, only focus on the time is takes to complete the step 4, typically expressed in Millions Instructions Per Second (MIPS) while the real-time challenge for designers is to minimize the time between Sample to Output: the real-time MCU architecture choice is critical.

The C2000 real-time MCU is a scalable, ultra-low latency, real-time controller platform designed for efficiency in power electronics, such as high power density, high switching frequencies, GaN and SiC technologies and was designed with the best Real-Time Signal Chain performance in mind and can deliver 2-times more real-time signal chain performance than an Arm®-based architecture.

The following sections showcase these advantages in terms of CPU cycle counts for easy comparison:

- Accelerated Trignometric Math Functions

- Understanding Flash Memory Performance in Real-Time Control Applications

The next sections will zoom in each key elements that enables C2000 MCUs to deliver the best real-time signal performance in the market. Backed up with 25 years of expertise, which has translated in the largest reference design offering for power conversion in the industry, coming with robust production ready software and open source hardware documentation, designers can now innovate to and build energy system of the future. The C2000 real-time MCU continues to expand with a platform of software compatible device from the low-end to the high-end. Check the home page on TI.com and register for the TI newsletter to stay up to date on new innovations from C2000 real-time MCUs.