SNOAA68 June 2021 LMG3410R050 , LMG3410R070 , LMG3410R150 , LMG3411R050 , LMG3411R070 , LMG3411R150 , LMG3422R030 , LMG3422R050 , LMG3425R030 , LMG3425R050 , LMG3522R030-Q1 , LMG3526R030

8 System-Level Reliability and Protection

Two important aspects of TI GaN products are their reliable operation in power supplies and the built-in protection functions that can improve system-level reliability. These aspects are built upon a reliable GaN device foundation, shown in Figure 8-1. The system-level protections include overtemperature and overcurrent protection, and undervoltage lockout. In addition, the low-inductance leadframe minimizes ringing and related voltage overstress, thereby improving reliability.

Figure 8-1 System-level reliability and protections of TI GaN products are built on a solid device foundation.

System-level reliability is validated through the JESD47 High Temperature Operating Life (HTOL) test, the JEP180 Dynamic (DHTOL) test, and the lightning surge test described in Section 7. We run the JESD47 HTOL test with 3 lots × 77 parts of the product at maximum recommended voltages and temperatures in HTOL boards. Hard-switching under the conditions of power conversion applications is not feasible in socketed HTOL boards, so the HTOL test is designed to exercise both the off-state and functional-switching reliability of the MCM product. Hard-switching under the conditions of power conversion applications is performed per the JEP180 DHTOL testing guideline using half-bridge cards in an H-bridge configuration. The half-bridge cards are based upon our customer Evaluation Module (EVM), and are inserted into an array of H-bridge motherboards, as shown in Figure 8-2.

Figure 8-2 Dynamic HTOL (DHTOL) is run using an H-bridge cell comprising two half-bridge cards. Both hard and soft-switching stress is applied.

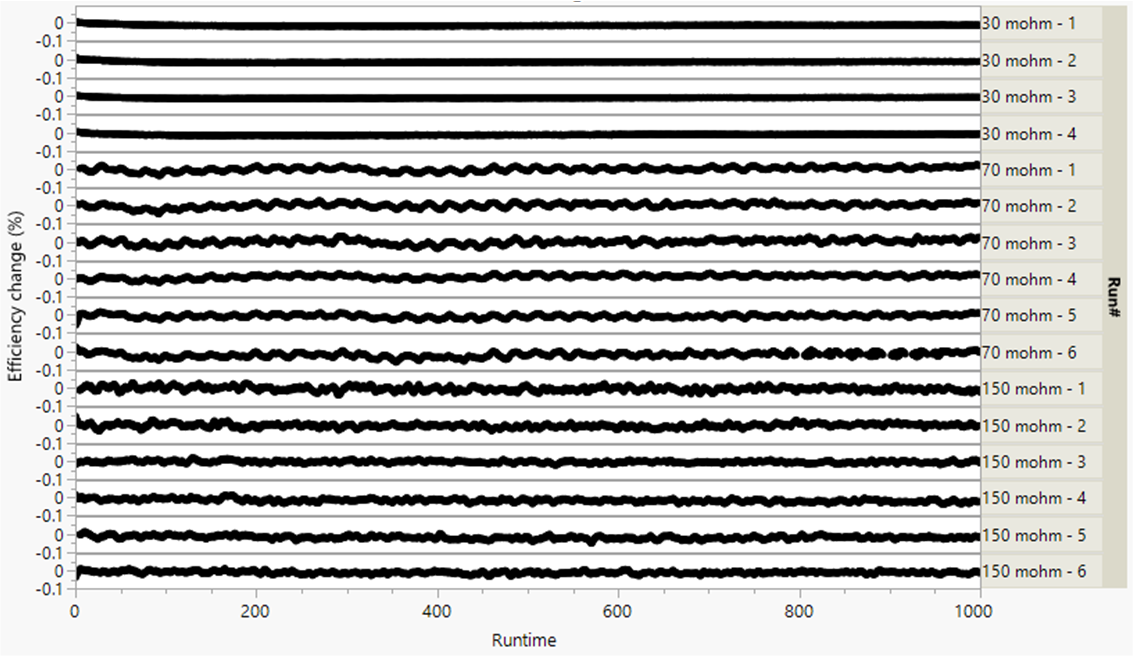

The cards are stressed using JEP180 best-practice conditions of maximum recommended voltage, temperature, and power levels and run for 1000 h with parts stressed under both hard- and soft-switching conditions. The test validates both hard and soft-switching reliability by applying system-level stress to the part. It also assures there are no failures from other modes like third quadrant operation and hard-commutation. It further checks the robustness of interactions, for example, with the other die in the MCM, the other half-bridge GaN part, or with other components typically used in power supplies. The parts show stable efficiency and they run without fail, as shown in Figure 8-3, which shows DHTOL results on 32 half-bridge cards (64 parts) from the LMG34xx product family from multiple fabrication lots. The stress conditions are listed in the figure caption. Each trellis in Figure 8-3 shows the efficiency change of one H-bridge cell (4 parts), calculated from the loss current needed to power the cell. The efficiency remained within 0.1% of its initial value, demonstrating the good system-level reliability of TI GaN products. The result provides confidence that parts will operate stably as they age. This is due to their excellent dynamic RDS(ON) stability, previously shown under conditions of both hard switching and off-state stress. The DHTOL test also validates that the switching transition remains clean, without shoot-though effects at high slew rates of 100 V/ns.

Figure 8-3 Dynamic HTOL (DHTOL) results on LMG3410 TI GaN parts run at 480V/125C, 150 kHz, 100 V/ns slew rate and maximum-power stress conditions for 1000h. Power levels used were: 3.8 kW for 30 mΩ, 1.9 kW for 50 mΩ, 1.4 kW for 150 mΩ. Parts run stably without failure, and efficiency remained within 0.1%. demonstrating good in-system reliability.