SWRA705 August 2021 AWR1243 , AWR1443 , AWR1642 , AWR1843 , AWR1843AOP , AWR2243 , AWR2944 , AWR6443 , AWR6843 , AWR6843AOP , AWRL1432 , AWRL6432 , IWR1443 , IWR1642 , IWR1843 , IWR2243 , IWR2944 , IWR6243 , IWR6443 , IWR6843 , IWR6843AOP , IWRL6432 , IWRL6432AOP

2.3 Radome Wall Thickness

The wall thickness of the radome plays a key role in arriving at the optimum performance of the mmWave radar sensor. It is important to make sure that the radome wall thickness is equal to an integer multiple of the radar wavelength/2 so that the radome becomes “nearly transparent” for the mmWave frequency range intended. The thickness of radome is given in Equation 3. The wavelength in the radome material becomes shorter versus free air and is an inverse function of the material's dielectric constant as shown in Equation 4.

Where,

- toptimum = Optimum thickness of radome wall or target thickness to make the radome transparent.

- n: 1,2,3…

- λm: Wavelength of the material

- C: speed of light

- f: mean carrier frequency used (for example, 62 GHz for a typical 60-64 GHz bandwidth)

- εr : relative permittivity

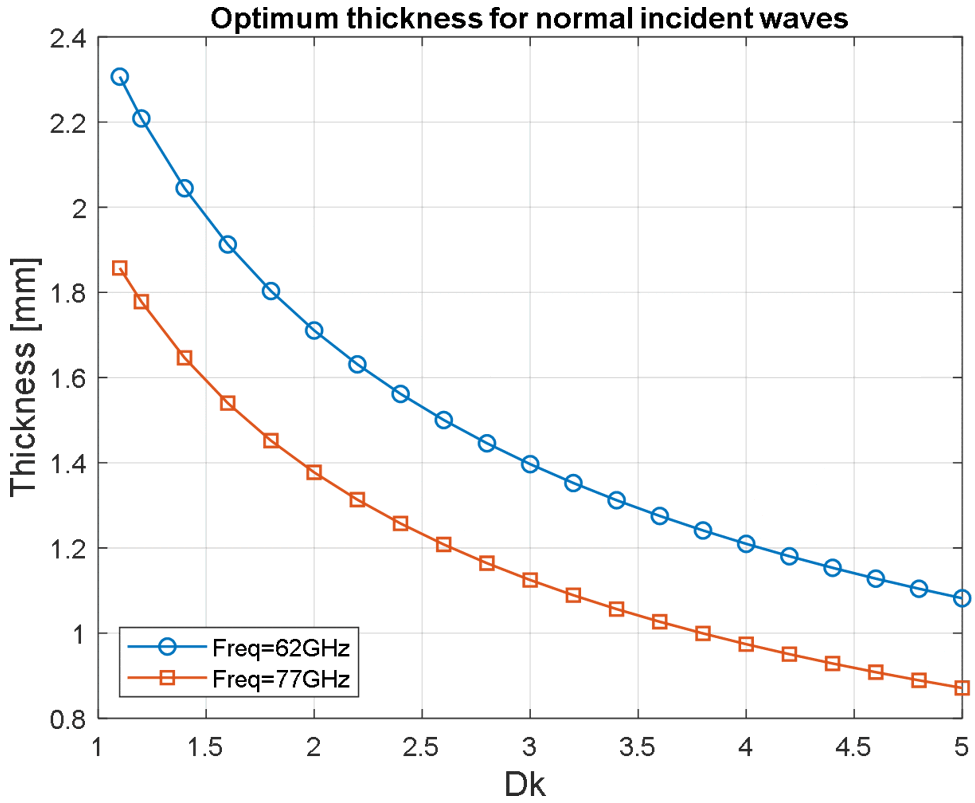

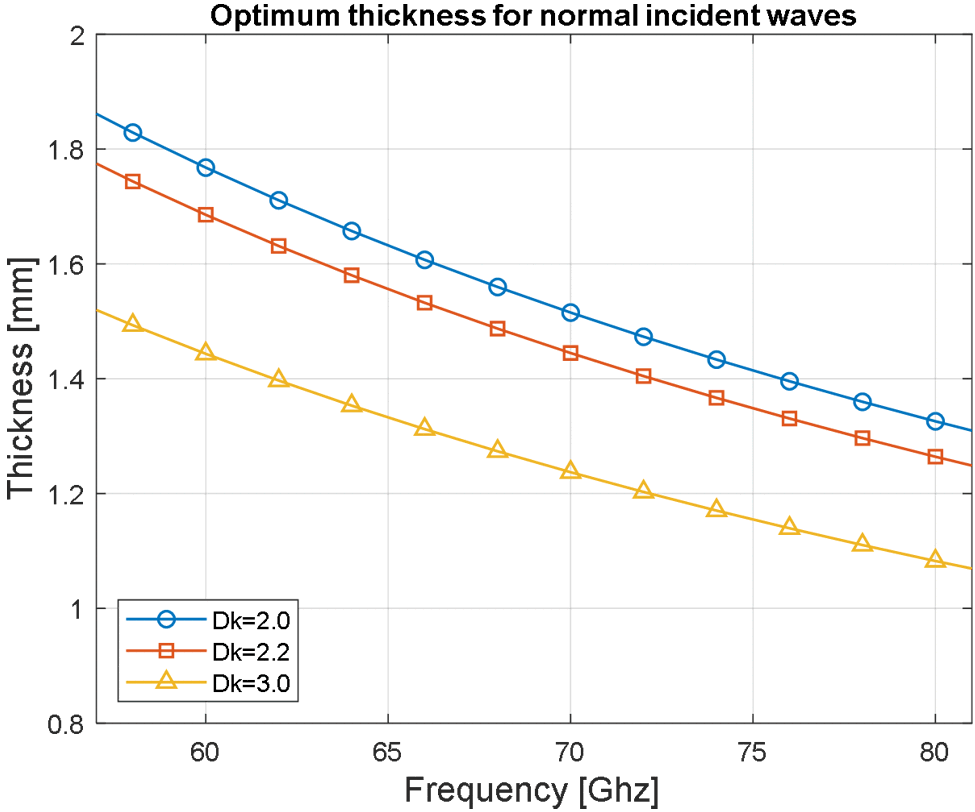

In general, radome performance depends mainly on the frequency of use, thickness, εr, incident angle, and shape. For the normal incident case, optimum thickness given in Equation 4 is plotted in Figure 2-4 and Figure 2-5.

Figure 2-4 Radome Optimal Thickness

versus Dielectric for Incident Waves of Different Frequency

Figure 2-4 Radome Optimal Thickness

versus Dielectric for Incident Waves of Different Frequency Figure 2-5 Radome Optimal Thickness

versus Frequency for Different Dielectrics

Figure 2-5 Radome Optimal Thickness

versus Frequency for Different Dielectrics