JAJU732C June 2019 – July 2022

- 概要

- Resources

- 特長

- アプリケーション

- 5

- 1System Description

- 2System Overview

- 3Circuit Description

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Design Files

- 6Related Documentation

- 7Terminology

- 8About the Author

- 9Revision History

4.4.1 Lab 1

Compile the project by selecting Lab 1: Open Loop PWM in the drop-down menu of Project Options from PowerSUITE GUI. This lab is intended to validate the PWM outputs and can be checked directly using TIDA-010054 HW or using the F2804X control card with a docking station.

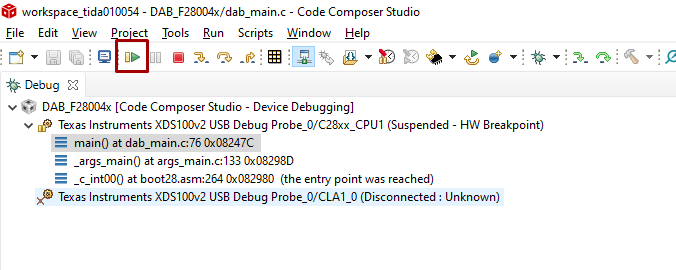

Run the project by clicking the green run button in CCS.

Figure 4-10 Run CCS

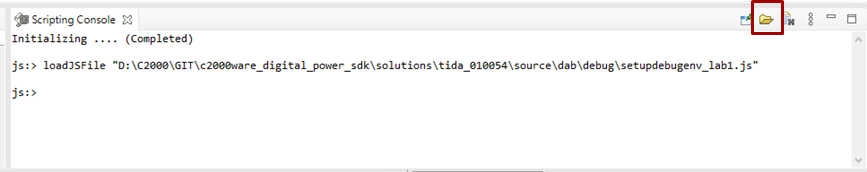

Figure 4-10 Run CCSPopulate the required variables in the watch window by loading javascript ' setupdebugenv_lab1.js' in the scripting console.

Figure 4-11 Loading Labs

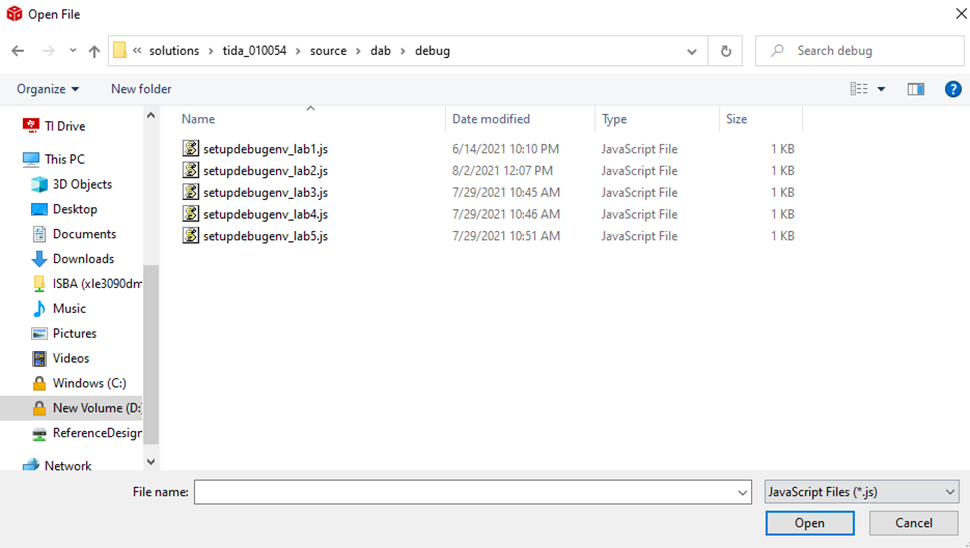

Figure 4-11 Loading Labs Figure 4-12 Select a Lab

Figure 4-12 Select a Lab- After running the script, the

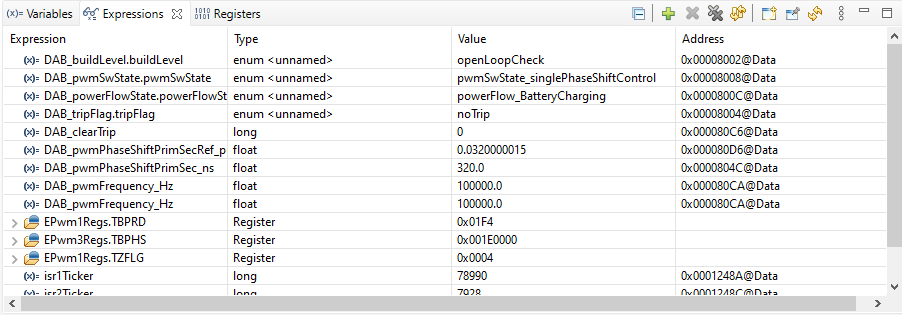

watch window is populated with the variables in Figure 4-13.

Figure 4-13 Watch Window

Figure 4-13 Watch Window - Enable PWM by writing “1” to the DAB_clearTrip variable. (This variable resets to zero post writing and its normal)

- Pass

criteria for Lab1

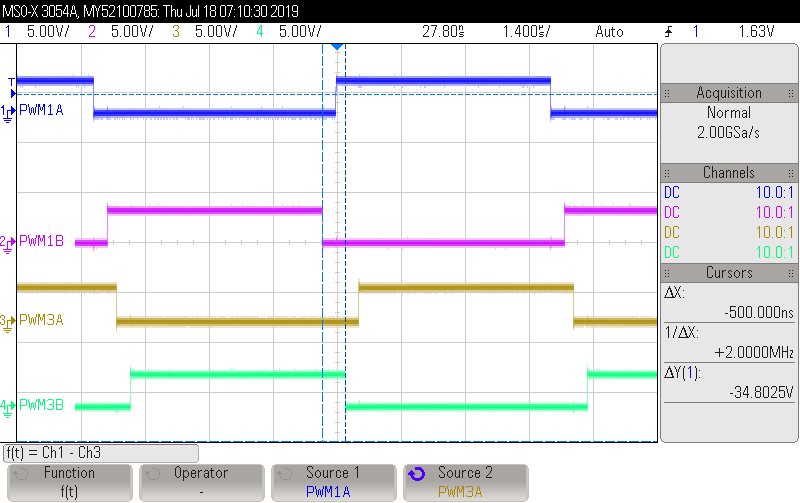

Connect probes on PWM1A (Q1), PWM1B (Q2), PWM3A(Q5), and PWM3B (Q6).

1A and 1B are a complimentary pair, 3A is in sync with 1A with the specified phase shift, and the phase shift is controlled by the variable, DAB_pwmPhaseShiftPrimSecRef_pu.

Check the following:

- Frequency is 100 kHz

Figure 4-14 100 kHz

PWM

Figure 4-14 100 kHz

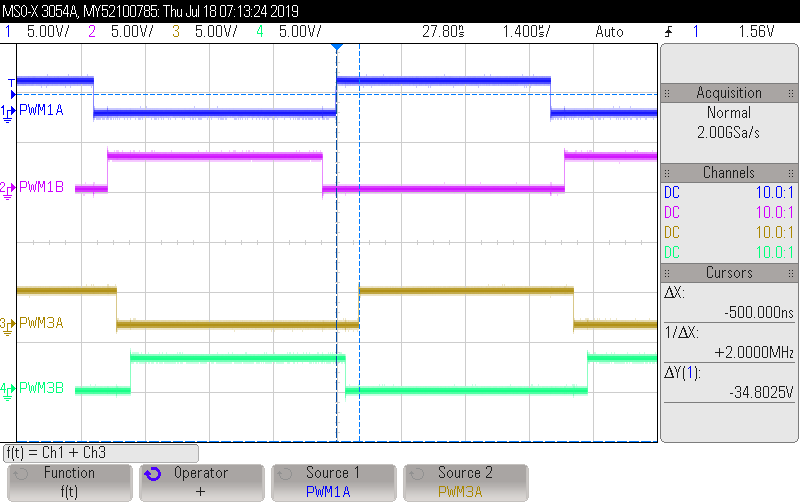

PWM - Now change the phase shift to 0.05 → 500 ns, to see more observable

phase shift

Figure 4-15 Phase Shift

500 ns

Figure 4-15 Phase Shift

500 ns - Phase shift matches that specified by the variable on the oscilloscope.

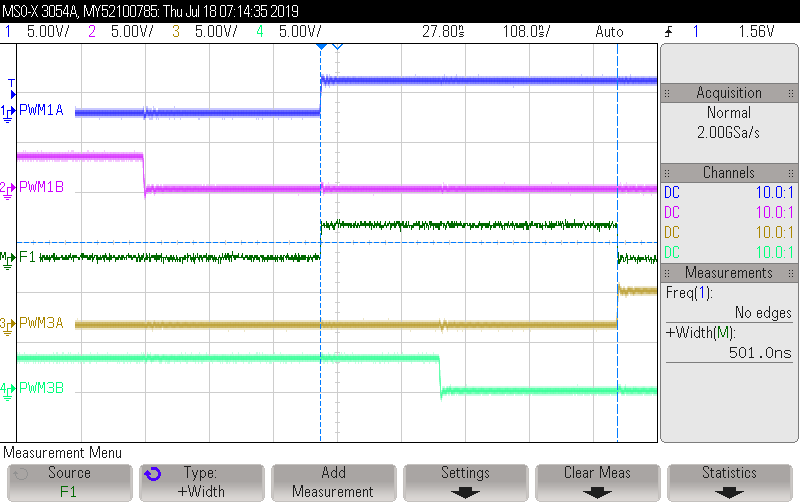

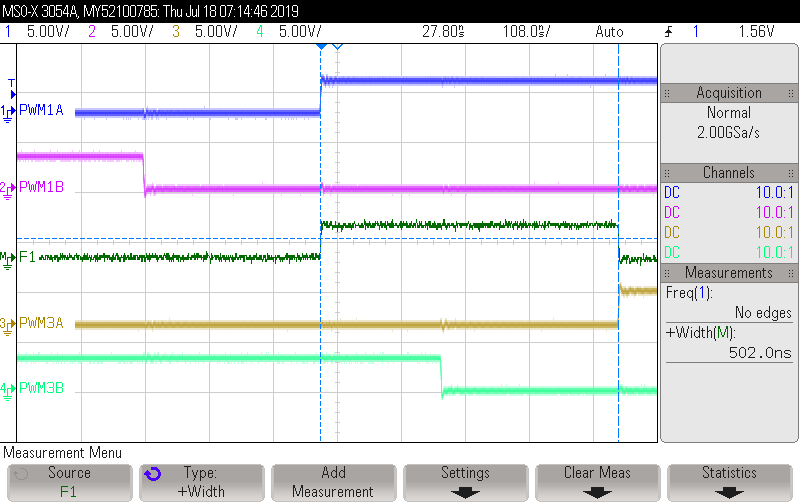

Check for non-clock ticks, that is, sub 10-ns internals of phase shift

to verify high-resolution operation. In Figure 4-16 and

Figure 4-17, the

phase shift is measured using the oscilloscope to be approximately 500

ns for 500-ns setpoint and approximately 502 ns for a 502-ns setpoint,

small jitter approximately 1–2 ns can be the measurement error. CAUTION: Phase shift is not recommended to be operated beyond 0.45 pu.

Figure 4-16 High

Resolution Phase Shift 500 ns (1 ns Jitter Error)

Figure 4-16 High

Resolution Phase Shift 500 ns (1 ns Jitter Error) Figure 4-17 High

Resolution Phase Shift 502 ns

Figure 4-17 High

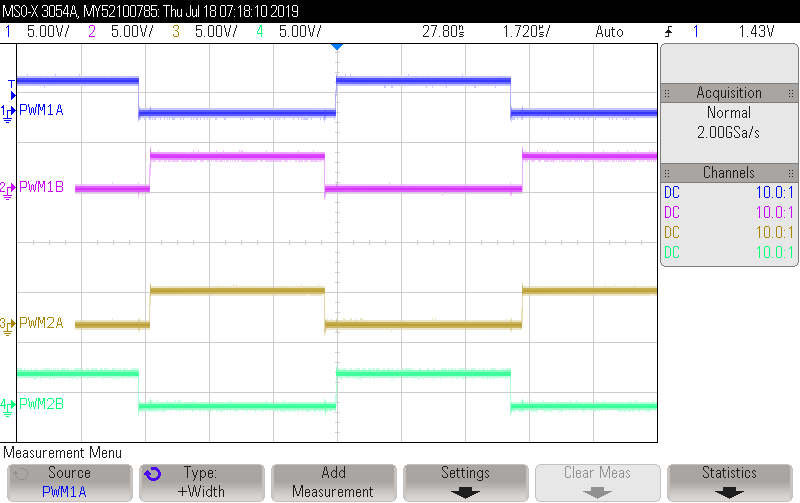

Resolution Phase Shift 502 ns - Change the PWM probes to PWM1A, PWM1B, PWM2A, and PWM2B.

- Verify PWM1A and 2B are in sync and in phase

- Verify PWM1B and 2A are in sync and in phase

Figure 4-18 PWM in

Sync

Figure 4-18 PWM in

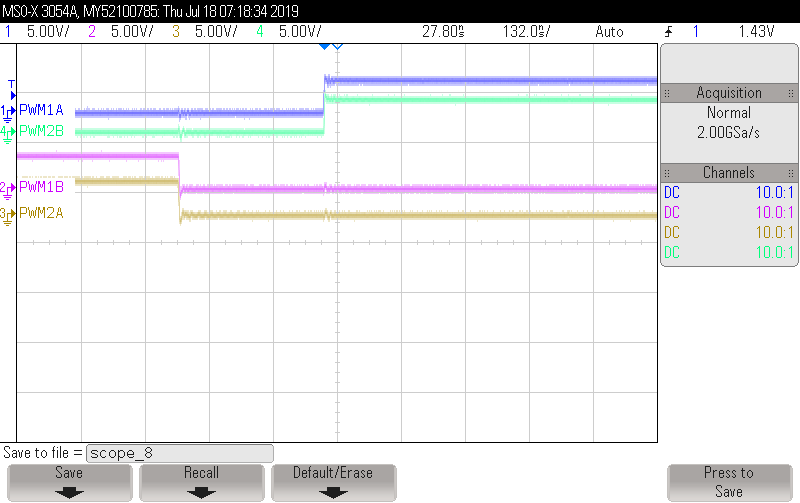

Sync - Verify that they remain in sync and in phase as the phase shift for sec

side PWM is changed:

Figure 4-19 PWM in Sync

With Phase Shift

Figure 4-19 PWM in Sync

With Phase Shift

- Frequency is 100 kHz