SPRUHJ1I January 2013 – October 2021 TMS320F2802-Q1 , TMS320F28026-Q1 , TMS320F28026F , TMS320F28027-Q1 , TMS320F28027F , TMS320F28027F-Q1 , TMS320F28052-Q1 , TMS320F28052F , TMS320F28052F-Q1 , TMS320F28052M , TMS320F28052M-Q1 , TMS320F28054-Q1 , TMS320F28054F , TMS320F28054F-Q1 , TMS320F28054M , TMS320F28054M-Q1 , TMS320F2806-Q1 , TMS320F28062-Q1 , TMS320F28062F , TMS320F28062F-Q1 , TMS320F28068F , TMS320F28068M , TMS320F28069-Q1 , TMS320F28069F , TMS320F28069F-Q1 , TMS320F28069M , TMS320F28069M-Q1

- 1 Read This First

-

1 Introduction

- 1.1 An Overview of InstaSPIN-FOC™ and FAST™

- 1.2

An Overview of InstaSPIN-MOTION™ and SpinTAC™

- 1.2.1 InstaSPIN-MOTION™ Key Capabilities and Benefits

- 1.2.2 InstaSPIN-MOTION™ Block Diagrams

- 1.2.3 Application Examples

- 2 Quick Start Kits - TI Provided Software and Hardware

-

3 InstaSPIN™ and MotorWare™

- 3.1 Overview

- 3.2 MotorWare™ Directory Structure

- 3.3 MotorWare™ Object-Oriented Design

- 3.4

InstaSPIN-FOC™ API

- 3.4.1

Controller API Functions – ctrl.c, ctrl.h,

CTRL_obj.h

- 3.4.1.1 CTRL Enumerations and Structures

- 3.4.1.2 CTRL State Control and Error Handling

- 3.4.1.3

CTRL Get Functions

- CTRL_getCount_current ()

- CTRL_getCount_isr ()

- CTRL_getCount_speed ()

- CTRL_getCount_state ()

- CTRL_getCount_traj ()

- CTRL_getCtrlFreq ()

- CTRL_getCtrlPeriod_sec ()

- CTRL_getErrorCode ()

- CTRL_getEstHandle ()

- CTRL_getFlag_enableCtrl ()

- CTRL_getFlag_enableDcBusComp ()

- CTRL_getFlag_enablePowerWarp ()

- CTR CTRL_getFlag_enableOffset ()

- CTRL_getFlag_enableSpeedCtrl ()

- CTRL_getFlag_enableUserMotorParams ()

- CTRL_getGains ()

- CTRL_getIab_filt_pu ()

- CTRL_getIab_filt_addr ()

- CTRL_getIab_in_addr ()

- CTRL_getIab_in_pu ()

- CTRL_getId_in_pu ()

- CTRL_getId_ref_pu ()

- CTRL_getIdq_in_addr ()

- CTRL_getIdq_in_pu ()

- CTRL_getIdq_ref_pu ()

- CTRL_getIdRated_pu ()

- CTRL_getIq_in_pu ()

- CTRL_getIq_ref_pu ()

- CTRL_getKi ()

- CTRL_getKd ()

- CTRL_getKp ()

- CTRL_getLhf ()

- CTRL_getMagCurrent_pu ()

- CTRL_getMaxVsMag_pu ()

- CTRL_getMaximumSpeed_pu ()

- CTRL_getMotorRatedFlux ()

- CTRL_getMotorType ()

- CTRL_getNumCtrlTicksPerCurrentTick ()

- CTRL_getNumCtrlTicksPerSpeedTick ()

- CTRL_getNumCtrlTicksPerTrajTick ()

- CTRL_getNumIsrTicksPerCtrlTick ()

- CTRL_getRefValue_pu ()

- CTRL_getRhf ()

- CTRL_getRoverL ()

- CTRL_getSpd_max_pu ()

- CTRL_getSpd_out_addr ()

- CTRL_getSpd_out_pu ()

- CTRL_getSpd_ref_pu ()

- CTRL_getSpd_int_ref_pu ()

- CTRL_getState ()

- CTRL_getTrajFreq ()

- CTRL_getTrajPeriod_sec ()

- CTRL_getTrajStep ()

- CTRL_getUi ()

- CTRL_getVab_in_pu ()

- CTRL_getVab_out_addr ()

- CTRL_getVab_out_pu ()

- CTRL_getVd_out_addr ()

- CTRL_getVd_out_pu ()

- CTRL_getVdq_out_addr ()

- CTRL_getVdq_out_pu ()

- CTRL_getVersion ()

- CTRL_getVq_out_addr ()

- CTRL_getVq_out_pu ()

- CTRL_getWaitTime ()

- 3.4.1.4 CTRL Counter Functions

- 3.4.1.5

CTRL Set Functions

- CTRL_setCtrlFreq_Hz ()

- CTRL_setCtrlFreq_sec ()

- CTRL_setErrorCode ()

- CTRL_setEstParams ()

- CTRL_setFlag_enableCtrl ()

- CTRL_setFlag_enableDcBusComp ()

- CTRL_setFlag_enablePowerWarp ()

- CTRL_setFlag_enableOffset ()

- calibrationCTRL_setFlag_enableSpeedCtrl ()

- CTRL_setFlag_enableUserMotorParams ()

- CTRL_setGains ()

- CTRL_setIab_in_pu ()

- CTRL_setIab_filt_pu ()

- CTRL_setId_ref_pu ()

- CTRL_setIdq_in_pu ()

- CTRL_setIdq_ref_pu ()

- CTRL_setIdRated_pu ()

- CTRL_setIq_ref_pu ()

- CTRL_setKd ()

- CTRL_setKi ()

- CTRL_setKp ()

- CTRL_setLhf ()

- CTRL_setMagCurrent_pu ()

- CTRL_setMaxVsMag_pu ()

- CTRL_setMaxAccel_pu ()

- CTRL_setMaximumSpeed_pu ()

- CTRL_setParams()

- CTRL_setNumCtrlTicksPerCurrentTick ()

- CTRL_setNumCtrlTicksPerSpeedTick ()

- CTRL_setNumCtrlTicksPerTrajTick ()

- CTRL_setNumIsrTicksPerCtrlTick ()

- CTRL_setRhf ()

- CTRL_setRoverL ()

- CTRL_setSpdMax ()

- CTRL_setSpd_max_pu ()

- CTRL_setSpd_out_pu ()

- CTRL_setSpd_ref_pu ()

- CTRL_setSpd_ref_krpm ()

- CTRL_setState ()

- CTRL_setTrajFreq_Hz ()

- CTRL_setTrajPeriod_sec ()

- CTRL_setUi ()

- CTRL_setupClarke_I ()

- CTRL_setupClarke_V ()

- CTRL_setupEstIdleState ()

- CTRL_setupEstOnLineState ()

- CTRL_setUserMotorParams ()

- CTRL_setVab_in_pu ()

- CTRL_setVab_out_pu ()

- CTRL_setVdq_out_pu ()

- CTRL_setWaitTimes ()

- CTRL_setup ()

- CTRL_setupCtrl ()

- CTRL_setupEst ()

- CTRL_setupTraj ()

- 3.4.1.6 CTRL Run and Compute Functions

- 3.4.2

Estimator API Functions – FAST™ Library – est.h,

est_states.h

- 3.4.2.1 EST Enumerations and Structures

- 3.4.2.2

EST Set Functions

- EST_setRsOnLineId_pu ()

- EST_setAngle_pu ()

- EST_setDcBus_pu ()

- EST_setDir_qFmt ()

- EST_setFe_neg_max_pu ()

- EST_setFe_pos_min_pu ()

- EST_setFlag_enableFluxControl ()

- EST_setFlag_enableForceAngle ()

- EST_setFlag_enableRsOnLine ()

- EST_setFlag_enableRsRecalc ()

- EST_setFlag_estComplete ()

- EST_setFlag_updateRs ()

- EST_setForceAngleDelta_pu ()

- EST_setFreqB0_lp_pu ()

- EST_setFreqBeta_lp_pu ()

- EST_setFullScaleCurrent ()

- EST_setFullScaleFlux ()

- EST_setFullScaleFreq ()

- EST_setFullScaleInductance ()

- EST_setFullScaleResistance ()

- EST_setFullScaleVoltage ()

- EST_setIdle ()

- EST_setIdle_all ()

- EST_setId_ref_pu ()

- EST_setIdRated_pu ()

- EST_setIq_ref_pu ()

- EST_setLs_d_pu ()

- EST_setLs_delta_pu ()

- EST_setLs_dq_pu ()

- EST_setLs_q_pu ()

- EST_setLs_qFmt ()

- EST_setMaxAccel_pu ()

- EST_setMaxAccel_est_pu ()

- EST_setMaxCurrentSlope_pu ()

- EST_setMaxCurrentSlope_PowerWarp_pu ()

- EST_setRr_pu ()

- EST_setRr_qFmt ()

- EST_setRs_delta_pu ()

- EST_setRsOnLine_pu ()

- EST_setRsOnLine_qFmt ()

- EST_setRsOnLineFilterParams ()

- EST_setRsOnLineId_mag_pu ()

- EST_setRs_pu ()

- EST_setRs_qFmt ()

- EST_updateId_ref_pu ()

- 3.4.2.3

EST Get Functions

- EST_get_krpm_to_pu_sf ()

- EST_get_pu_to_krpm_sf ()

- EST_getAngle_pu ()

- EST_getDcBus_pu ()

- EST_ErrorCode_e EST_getErrorCode ()

- EST_getFe ()

- EST_getFe_pu ()

- EST_getFlag_enableForceAngle ()

- EST_getFlag_enableRsOnLine ()

- EST_getFlag_enableRsRecalc ()

- EST_getFlag_estComplete ()

- EST_getFlag_updateRs ()

- EST_getFlux_VpHz ()

- EST_getFlux_Wb ()

- EST_getFlux_pu ()

- EST_getFm ()

- EST_getFm_pu ()

- EST_getForceAngleDelta_pu ()

- EST_getForceAngleStatus ()

- EST_getFreqB0_lp_pu ()

- EST_getFreqBeta_lp_pu ()

- EST_getFslip ()

- 280

- EST_getFslip_pu ()

- EST_getFullScaleCurrent ()

- EST_getFullScaleFlux ()

- EST_getFullScaleFreq ()

- EST_getFullScaleInductance ()

- EST_getFullScaleResistance ()

- EST_getFullScaleVoltage ()

- EST_getIdRated ()

- EST_getIdRated_pu ()

- EST_getIdRated_indEst_pu ()

- EST_getIdRated_ratedFlux_pu ()

- EST_getLr_H ()

- EST_getLr_pu ()

- EST_getLr_qFmt ()

- EST_getLs_d_H ()

- EST_getLs_d_pu ()

- EST_getLs_delta_pu ()

- EST_getLs_dq_pu ()

- EST_getLs_q_H ()

- EST_getLs_q_pu ()

- EST_getLs_qFmt ()

- EST_getLs_max_pu ()

- EST_getLs_min_pu ()

- EST_getLs_coarse_max_pu ()

- EST_getMaxAccel_pu ()

- EST_getMaxAccel_est_pu ()

- EST_getMaxCurrentSlope_pu ()

- EST_getMaxCurrentSlope_PowerWarp_pu ()

- EST_getOneOverDcBus_pu ()

- EST_getRr_Ohm ()

- EST_getRr_pu ()

- EST_getRr_qFmt ()

- EST_getRs_delta_pu ()

- EST_getRs_Ohm ()

- EST_getRs_pu ()

- EST_getRs_qFmt ()

- EST_getRs_qFmt ()

- EST_getRsOnLine_Ohm ()

- EST_getRsOnLine_pu ()

- EST_getRsOnLineId_mag_pu ()

- EST_getRsOnLineId_pu ()

- EST_getSpeed_krpm ()

- EST_getSignOfDirection ()

- EST_getSpeed_krpm ()

- EST_getState ()

- EST_getTorque_lbin ()

- EST_getTorque_Nm ()

- EST_getDir_qFmt ()

- 3.4.2.4 EST Run and Compute Functions

- 3.4.2.5 EST Counter Functions

- 3.4.2.6 EST State Control and Error Handling Functions

- 3.4.3

Hardware Abstraction Layer (HAL) API Functions – hal.c, hal.h, hal_obj.h

- 3.4.3.1 HAL Enumerations and Structures

- 3.4.3.2

HAL – ADC and AFE

- HAL_setupAdcs ()

- HAL_setupAfe ()

- HAL_acqAdcInt ()

- HAL_readAdcData()

- HAL_updateAdcBias ()

- HAL_setBias ()

- HAL_getBias ()

- HAL_cal ()

- HAL_AdcCalConversion ()

- HAL_AdcOffsetSelfCal ()

- HAL_getAdcSocSampleDelay ()

- HAL_setAdcSocSampleDelay ()

- HAL_getCurrentScaleFactor ()

- HAL_setCurrentScaleFactor ()

- HAL_getVoltageScaleFactor ()

- HAL_setVoltageScaleFactor ()

- HAL_getNumCurrentSensors ()

- HAL_setNumCurrentSensors ()

- HAL_getNumVoltageSensors ()

- HAL_setNumVoltageSensors ()

- 377

- HAL_getOffsetBeta_lp_pu ()

- HAL_setOffsetBeta_lp_pu ()

- HAL_setOffsetInitCond ()

- HAL_getOffsetValue ()

- HAL_setOffsetValue ()

- HAL_runOffsetEst ()

- 3.4.3.3 HAL – PWM and PWM-DAC

- 3.4.3.4 HAL – CPU Timers

- 3.4.3.5 HAL – GPIO and LED

- 3.4.3.6

HAL – Miscellaneous

- HAL_init()

- HAL_initIntVectorTable ()

- HAL_setParams ()

- HAL_setupFlash ()

- HAL_setupPie ()

- HAL_setupPll ()

- HAL_setupPeripheralClks ()

- HAL_getOscTrimValue ()

- HAL_OscTempComp ()

- HAL_osc1Comp ()

- HAL_osc2Comp ()

- HAL_setupFaults ()

- HAL_setParams()

- HAL_enableDebugInt ()

- HAL_enableGlobalInts ()

- HAL_disableGlobalInts ()

- HAL_disableWdog ()

- 3.4.4 User Settings – user.c, user.h, userParams.h

- 3.4.5 Miscellaneous Functions

- 3.4.1

Controller API Functions – ctrl.c, ctrl.h,

CTRL_obj.h

- 3.5 InstaSPIN-MOTION™ and the SpinTAC™ API

- 3.6 SpinTAC™ API

-

4 User Parameters (user.h)

- 4.1

Currents and Voltages

- 4.1.1 USER_IQ_FULL_SCALE_FREQ_Hz

- 4.1.2 USER_IQ_FULL_SCALE_VOLTAGE_V

- 4.1.3 USER_ADC_FULL_SCALE_VOLTAGE_V

- 4.1.4 USER_VOLTAGE_SF

- 4.1.5 USER_IQ_FULL_SCALE_CURRENT_A

- 4.1.6 USER_ADC_FULL_SCALE_CURRENT_A

- 4.1.7 USER_CURRENT_SF

- 4.1.8 USER_NUM_CURRENT_SENSORS

- 4.1.9 USER_NUM_VOLTAGE_SENSORS

- 4.1.10 I_A_offset , I_B_offset , I_C_offset

- 4.1.11 V_A_offset , V_B_offset , V_C_offset

- 4.2 Clocks and Timers

- 4.3

Decimation

- 4.3.1 USER_NUM_PWM_TICKS_PER_ISR_TICK

- 4.3.2 USER_NUM_ISR_TICKS_PER_CTRL_TICK

- 4.3.3 USER_NUM_CTRL_TICKS_PER_CURRENT_TICK

- 4.3.4 USER_NUM_CTRL_TICKS_PER_EST_TICK

- 4.3.5 USER_NUM_CTRL_TICKS_PER_SPEED_TICK

- 4.3.6 USER_NUM_CTRL_TICKS_PER_TRAJ_TICK

- 4.3.7 USER_CTRL_FREQ_Hz

- 4.3.8 USER_EST_FREQ_Hz

- 4.3.9 USER_TRAJ_FREQ_Hz

- 4.3.10 USER_CTRL_PERIOD_usec

- 4.3.11 USER_CTRL_PERIOD_sec

- 4.4

Limits

- 4.4.1 USER_MAX_NEGATIVE_ID_REF_CURRENT_A

- 4.4.2 USER_ZEROSPEEDLIMIT

- 4.4.3 USER_FORCE_ANGLE_FREQ_Hz

- 4.4.4 USER_MAX_CURRENT_SLOPE_POWERWARP

- 4.4.5 USER_MAX_ACCEL_Hzps

- 4.4.6 USER_MAX_ACCEL_EST_Hzps

- 4.4.7 USER_MAX_CURRENT_SLOPE

- 4.4.8 USER_IDRATED_FRACTION_FOR_RATED_FLUX

- 4.4.9 USER_IDRATED_FRACTION_FOR_L_IDENT

- 4.4.10 USER_IDRATED_DELTA

- 4.4.11 USER_SPEEDMAX_FRACTION_FOR_L_IDENT

- 4.4.12 USER_FLUX_FRACTION

- 4.4.13 USER_POWERWARP_GAIN

- 4.4.14 USER_R_OVER_L_EST_FREQ_Hz

- 4.5 Poles

- 4.6

User Motor and ID Settings

- 4.6.1 USER_MOTOR_TYPE

- 4.6.2 USER_MOTOR_NUM_POLE_PAIRS

- 4.6.3 USER_MOTOR_Rr

- 4.6.4 USER_MOTOR_Rs

- 4.6.5 USER_MOTOR_Ls_d

- 4.6.6 USER_MOTOR_Ls_q

- 4.6.7 USER_MOTOR_RATED_FLUX

- 4.6.8 USER_MOTOR_MAGNETIZING_CURRENT

- 4.6.9 USER_MOTOR_RES_EST_CURRENT

- 4.6.10 USER_MOTOR_IND_EST_CURRENT

- 4.6.11 USER_MOTOR_MAX_CURRENT

- 4.6.12 USER_MOTOR_FLUX_EST_FREQ_Hz

- 4.6.13 USER_MOTOR_ENCODER_LINES (InstaSPIN-MOTION™ Only)

- 4.6.14 USER_MOTOR_MAX_SPEED_KRPM (InstaSPIN-MOTION™ Only)

- 4.6.15 USER_SYSTEM_INERTIA (InstaSPIN-MOTION™ Only)

- 4.6.16 USER_SYSTEM_FRICTION (InstaSPIN-MOTION™ Only)

- 4.6.17 USER_SYSTEM_BANDWIDTH_SCALE (InstaSPIN-MOTION™ Only)

- 4.7

SpinTAC™ Parameters (spintac_velocity.h and

spintac_position.h)

- 4.7.1

Macro Definitions

- 4.7.1.1 ST_MREV_ROLLOVER (spintac_position.h only)

- 4.7.1.2 ST_EREV_MAXIMUM (spintac_position.h only)

- 4.7.1.3 ST_POS_ERROR_MAXIMUM_MREV (spintac_position.h only)

- 4.7.1.4 ST_ISR_TICKS_PER_SPINTAC_TICK

- 4.7.1.5 ST_SPEED_SAMPLE_TIME

- 4.7.1.6 ST_SPEED_PU_PER_KRPM

- 4.7.1.7 ST_SPEED_KRPM_PER_PU

- 4.7.1.8 ST_MOTOR_INERTIA_PU

- 4.7.1.9 ST_MOTOR_FRICTION_PU

- 4.7.1.10 ST_MIN_ID_SPEED_RPM

- 4.7.1.11 ST_MIN_ID_SPEED_PU

- 4.7.1.12 ST_ID_INCOMPLETE_ERROR

- 4.7.1.13 ST_VARS_DEFAULTS

- 4.7.2 Type Definitions

- 4.7.3

Functions

- 4.7.3.1 ST_init

- 4.7.3.2 ST_setupPosConv

- 4.7.3.3 ST_setupVelCtl (Velocity Control Only)

- 4.7.3.4 ST_setupPosCtl (Position Control Only)

- 4.7.3.5 ST_setupVelMove (Velocity Control Only)

- 4.7.3.6 ST_setupPosMove (Position Control Only)

- 4.7.3.7 ST_setupVelPlan (Velocity Control Only)

- 4.7.3.8 ST_setupPosPlan (Position Control Only)

- 4.7.3.9 ST_setupVelId (Velocity Control Only)

- 4.7.3.10 ST_runPosConv

- 4.7.3.11 ST_runVelCtl (Velocity Control Only)

- 4.7.3.12 ST_runPosCtl (Position Control Only)

- 4.7.3.13 ST_runVelMove (Velocity Control Only)

- 4.7.3.14 ST_runPosMove (Position Control Only)

- 4.7.3.15 ST_runVelPlan (Velocity Control Only)

- 4.7.3.16 ST_runVelPlanTick (Velocity Control Only)

- 4.7.3.17 ST_runPosPlan (Position Control Only)

- 4.7.3.18 ST_runPosPlanTick (Position Control Only)

- 4.7.3.19 ST_runVelId (Velocity Control Only)

- 4.7.1

Macro Definitions

- 4.8 Setting ACIM Motor Parameters in user.h

- 4.1

Currents and Voltages

- 5 Managing Motor Signals

-

6 Motor Identification and State Diagrams

- 6.1 Overview

- 6.2 InstaSPIN™ Motor Identification

- 6.3 Motor Identification Process Overview

- 6.4 Differences between PMSM and ACIM Identification Process

- 6.5 Prerequisites

- 6.6

Full Identification of PMSM Motors

- 6.6.1 CTRL_State_Idle and EST_State_Idle

- 6.6.2 CTRL_State_OffLine and EST_State_Idle (Hardware Offsets Calibrated)

- 6.6.3 CTRL_State_OnLine and EST_State_RoverL

- 6.6.4 CTRL_State_OnLine and EST_State_Rs

- 6.6.5 CTRL_State_OnLine and EST_State_RampUp

- 6.6.6 CTRL_State_OnLine and EST_State_RatedFlux

- 6.6.7 CTRL_State_OnLine and EST_State_Ls

- 6.6.8 CTRL_State_OnLine and EST_State_RampDown

- 6.6.9 CTRL_State_OnLine and EST_State_MotorIdentified

- 6.6.10 CTRL_State_Idle and EST_State_Idle

- 6.7

Full Identification of ACIM Motors

- 6.7.1 CTRL_State_Idle and EST_State_Idle

- 6.7.2 CTRL_State_OffLine and EST_State_Idle

- 6.7.3 CTRL_State_OnLine and EST_State_RoverL

- 6.7.4 CTRL_State_OnLine and EST_State_Rs

- 6.7.5 CTRL_State_OnLine and EST_State_RampUp

- 6.7.6 CTRL_State_OnLine and EST_State_IdRated

- 6.7.7 CTRL_State_OnLine and EST_State_RatedFlux

- 6.7.8 CTRL_State_OnLine and EST_State_RampDown

- 6.7.9 CTRL_State_Idle and EST_State_LockRotor

- 6.7.10 CTRL_State_OnLine and EST_State_Ls

- 6.7.11 CTRL_State_OnLine and EST_State_Rr

- 6.7.12 CTRL_State_OnLine and EST_State_RampDown

- 6.7.13 CTRL_State_OnLine and EST_State_MotorIdentified

- 6.7.14 CTRL_State_Idle and EST_State_Idle

- 6.8

Recalibration of PMSM and ACIM Motor Identification

- 6.8.1 Recalibration of PMSM and ACIM Motors After Full Identification

- 6.8.2 Recalibration of PMSM and ACIM Motors after Using Parameters from user.h

- 6.9 Setting PMSM Motor Parameters in user.h

- 6.10

Troubleshooting Motor Identification

- 6.10.1

Troubleshooting PMSM Motor Identification

- 6.10.1.1 Identifying PMSM Motors When Load Cannot be Detached

- 6.10.1.2 Can Motor Rotate with the Attached Load?

- 6.10.1.3 Run First Three Steps of Identification

- 6.10.1.4 Run Using Motor Parameters from user.h

- 6.10.1.5 Troubleshooting Motor Shaft Stopping During Ramp-Up

- 6.10.1.6 Troubleshooting Motor Shaft for Smoother Ramp

- 6.10.1.7 Troubleshooting Flux Measurement

- 6.10.1.8 Troubleshooting Ls Identification

- 6.10.1.9 Identifying High-Cogging Torque PMSM Motors

- 6.10.2 Troubleshooting ACIM Motor Identification

- 6.10.1

Troubleshooting PMSM Motor Identification

- 7 Inertia Identification

-

8 MCU Considerations

- 8.1 Overview

- 8.2 InstaSPIN-Enabled Devices

- 8.3 ROM and User Memory Overview

- 8.4 Details on CPU Load and Memory Footprint Measurements

- 8.5 Memory Footprint

- 8.6 CPU Load

- 8.7 Digital and Analog Pins

- 9 Real-Time Structure

- 10Managing Startup Time

-

11Tuning Regulators

- 11.1 PI Controllers Introduction

- 11.2 PI Design for Current Controllers

- 11.3 PI Design for Speed Controllers

- 11.4 Calculating PI Gains Based On Stability and Bandwidth

- 11.5 Calculating Speed and Current PI Gains Based on Damping Factor

- 11.6 Considerations When Adding Poles to the Speed Loop

- 11.7 Speed PI Controller Considerations: Current Limits, Clamping and Inertia

- 11.8 Considerations When Designing PI Controllers for FOC Systems

- 11.9 Sampling and Digital Systems Considerations

-

12InstaSPIN-MOTION™ Controllers

- 12.1 Overview

- 12.2 Stability

- 12.3 Software Configuration for the SpinTAC™ Velocity Control

- 12.4 Optimal Performance in Speed Control

- 12.5 Software Configuration for SpinTAC™ Position Control

- 12.6 Optimal Performance in Position Control

-

13Trajectory Planning

- 13.1 InstaSPIN-MOTION™ Profile Generation

- 13.2 Software Configuration for SpinTAC™ Velocity Move

- 13.3 Software Configuration for SpinTAC™ Position Move

- 13.4

InstaSPIN-MOTION™ Sequence Planning

- 13.4.1 SpinTAC™ Velocity Plan Elements

- 13.4.2 SpinTAC™ Velocity Plan Element Limits

- 13.4.3 SpinTAC™ Velocity Plan Example: Washing Machine Agitation

- 13.4.4 SpinTAC™ Velocity Plan Example: Garage Door

- 13.4.5 SpinTAC™ Velocity Plan Example: Washing Machine

- 13.4.6 SpinTAC™ Position Plan Example: Vending Machine

- 13.5

Software Configuration for SpinTAC™ Velocity Plan

- 13.5.1 Include the Header File

- 13.5.2 Define the Size of the Configuration Array

- 13.5.3 Declare the Global Structure

- 13.5.4 Initialize the Configuration Variables

- 13.5.5 Call SpinTAC™ Velocity Plan

- 13.5.6 Call SpinTAC™ Velocity Plan Tick

- 13.5.7 Update SpinTAC™ Velocity Plan with SpinTAC™ Velocity Move Status

- 13.6 Troubleshooting SpinTAC™ Velocity Plan

- 13.7

Software Configuration for SpinTAC™ Position Plan

- 13.7.1 Include the Header File

- 13.7.2 Define the Size of the Configuration Array

- 13.7.3 Declare the Global Structure

- 13.7.4 Initialize the Configuration Variables

- 13.7.5 Call SpinTAC™ Position Plan

- 13.7.6 Call SpinTAC™ Position Plan Tick

- 13.7.7 Update SpinTAC™ Position Plan with SpinTAC™ Position Move Status

- 13.8 Troubleshooting SpinTAC™ Position Plan

- 13.9 Conclusion

-

14Managing Full Load at Startup, Low-Speed, and Speed

Reversal

- 14.1 Overview

- 14.2 Low-Speed Operation with Full Load

- 14.3 Speed Reversal with Full Load

- 14.4 Motor Startup with Full Load

- 14.5 Rapid Acceleration from Standstill With Full Load

- 14.6 Overloading and Motor Overheating

- 14.7 InstaSPIN-MOTION™ and Low-Speed Considerations

-

15Rs Online Recalibration

- 15.1 Overview

- 15.2 Resistance vs. Temperature

- 15.3 Accurate Rs Knowledge Needed at Low Speeds Including Startup

- 15.4 Introduction to Rs Online Recalibration

- 15.5 Rs Online vs. Rs Offline

- 15.6 Enabling Rs Online Recalibration

- 15.7 Disabling Rs Online Recalibration

- 15.8 Modifying Rs Online Parameters

- 15.9 Monitoring Rs Online Resistance Value

- 15.10 Using the Rs Online Feature as a Temperature Sensor

- 15.11 Rs Online Related State Diagrams (CTRL and EST)

- 16PowerWarp™

- 17Shunt Current Measurements

- 18Sensored Systems

11.7 Speed PI Controller Considerations: Current Limits, Clamping and Inertia

Up to now, we have only discussed the tuning problem in the context of a linear system. This is because under steady-state conditions when the system settles out, you will most likely find that you are operating in the linear region, and the AC signal content will be very small. Therefore, performing a small-signal (linear) analysis will tell you how stable your system will be when it is not operating in saturation. But in most real-life scenarios, the system will saturate because of limits on your voltage and/or current, especially under large transient conditions. This saturation effect can play an important role in the PI controller; especially the integrator. Since the maximum torque the motor can produce is limited by your current limit, the acceleration of the system is also limited. But the integrator doesn't know this, and it thinks it can make the motor speed up faster by increasing its output. This increased integrator output can't help the situation since the system is already saturated. All it does is create a very large output that will cause the system to overshoot when it does come out of saturation. For this reason, most PI integrator outputs are clamped to keep them from continuing to integrate needlessly when the system is saturated.

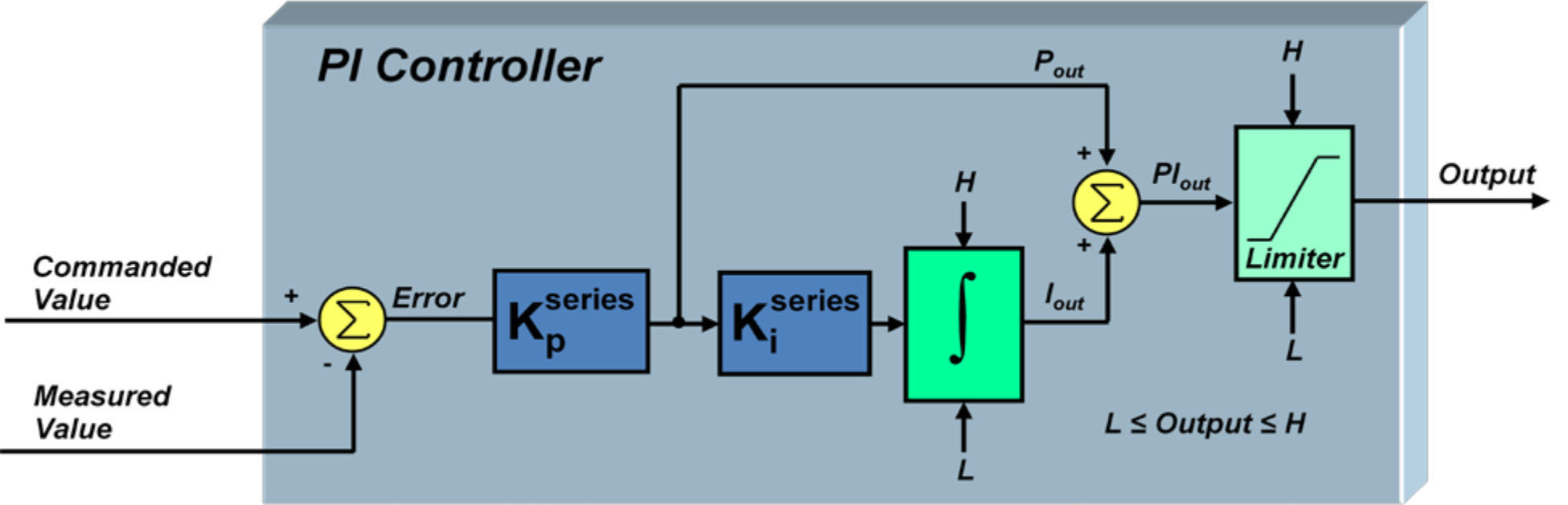

A simple static clamping scheme is illustrated in Figure 12-14. The most common scenario is to set the clamp values equal to the PI output limit values. For example, the output limit of a PI controller that regulates speed is usually what sets your current limit value since the speed PI output is the reference input signal for the current PI controller. However, there is nothing that says that the integrator limit must equal the PI output limit, and many designs use different clamp values based on the specific application.

Figure 11-14 PI Controller with Static Integrator Clamping

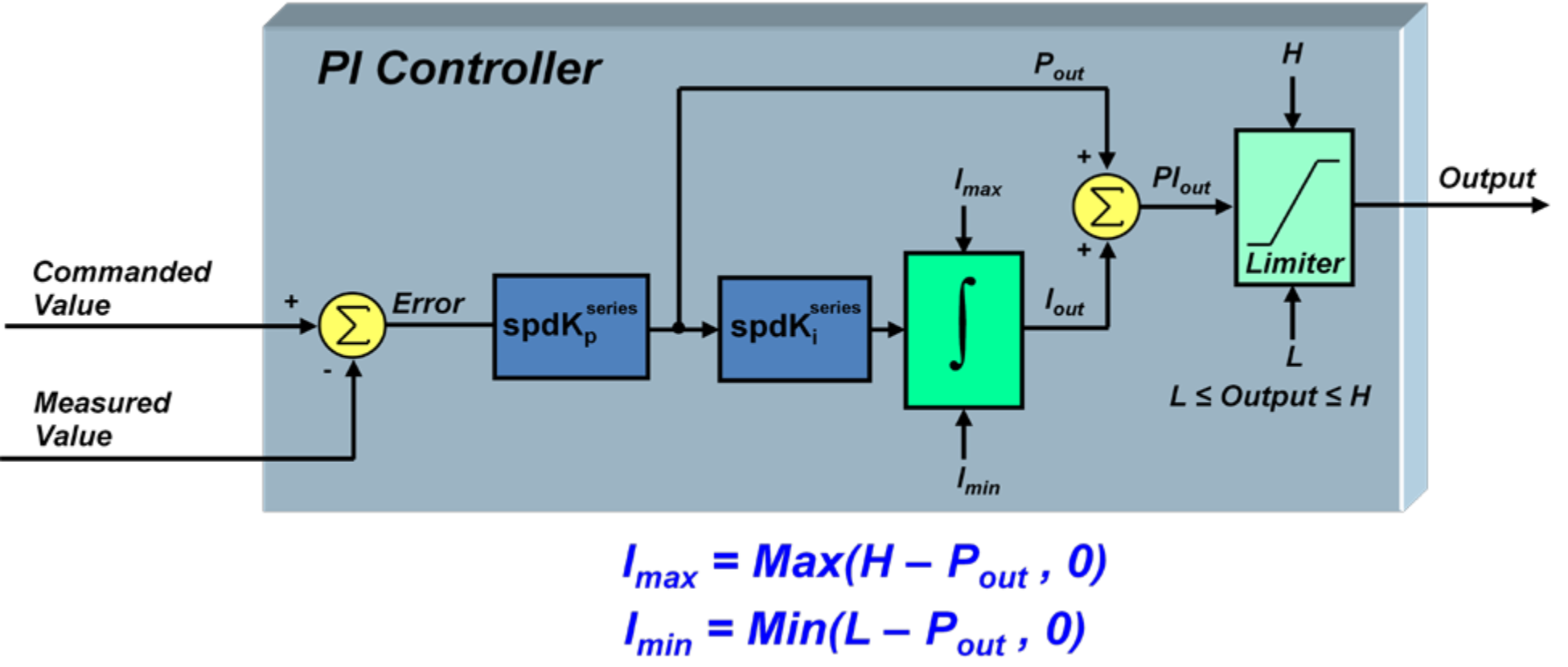

Figure 11-14 PI Controller with Static Integrator ClampingFigure 12-15 shows a dynamic clamping scheme which provides superior performance over the static scheme. The thinking behind the design of this scheme is based on the rationale that if the system is already saturated by the P gain output, then why continue integrating? Only during conditions where changes in the integrator output would result in changes in the PI controller output is the integrator allowed to continue to integrate error unconstrained.

Figure 11-15 PI Controller with Dynamic Integrator Clamping

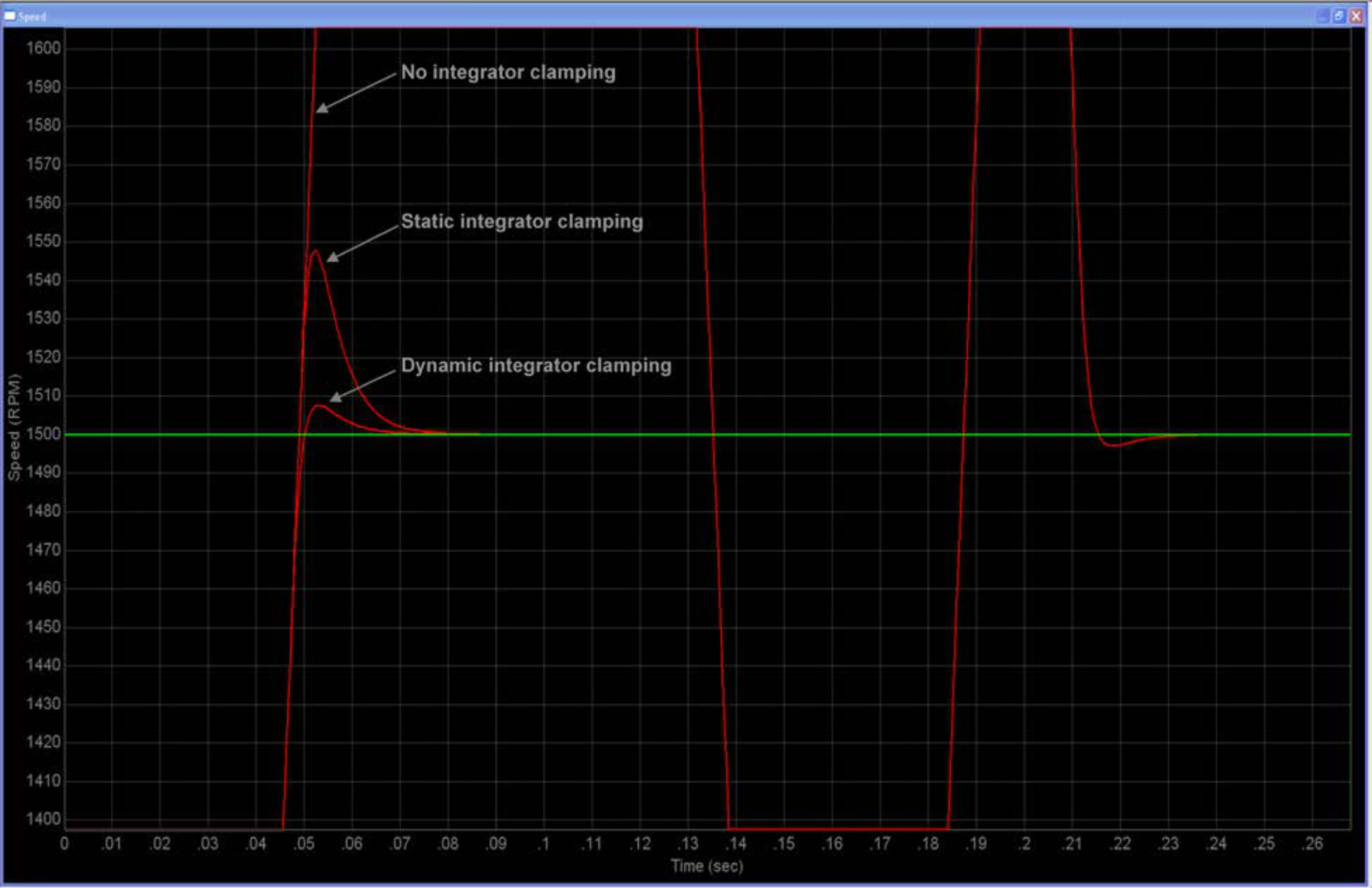

Figure 11-15 PI Controller with Dynamic Integrator ClampingThe effectiveness of integrator clamping can be seen by the simulated curves in Figure 12-16. Let's stimulate the system we designed in Section 6 with a commanded speed step from zero to a target speed of 1500 RPM. Shown are the effects of system overshoot under the conditions of no clamping, static clamping where the integrator clamp values equal the output clamp values and finally, dynamic clamping. As you can see, no integrator clamping at all is unacceptable as it results in extremely high overshoot which triggers further system saturation and oscillation. Static integrator clamping dramatically improves this situation. However, dynamic clamping improves performance even further, resulting in a 6 times improvement in the overshoot peak value compared to static clamping in this example.

Figure 11-16 Example Comparison of Integrator Clamping Techniques

Figure 11-16 Example Comparison of Integrator Clamping TechniquesAt this point, let's double-back and talk about a very important part of this whole discussion. Everything we have talked about in these seven sections is not very significant without knowing one critical piece of the system which is the inertia. Without this knowledge, there is no definitive way of stabilizing the speed loop. In many cases, you can calculate the inertia by knowing the form factor and mass distribution of your rotating load. If a gearhead is present on the motor shaft with a big enough gear ratio, the load inertia can often be ignored since transferred inertia is inversely proportional to the square of the turns ratio, and just deal with the motor inertia which is listed on most motor data sheets. If neither of these options is valid, there are several techniques used to measure inertia which usually involve some type of controlled acceleration, deceleration, or both. However, it is not common to see techniques which also take into consideration static torque loading on the motor shaft ("static," loads in this context mean loads which don't change as a function of time, such as friction or an elevator load). The following is a proposed (but at the time of this writing, untested) technique which should yield a better inertia estimate than the techniques mentioned above:

- Design the current controller using techniques discussed in the PI tuning sections.

- Set the PI coefficients for the speed loop to conservative values that will just allow spinning the motor up to speed (that is, having sluggish dynamic response should not be a concern at this point).

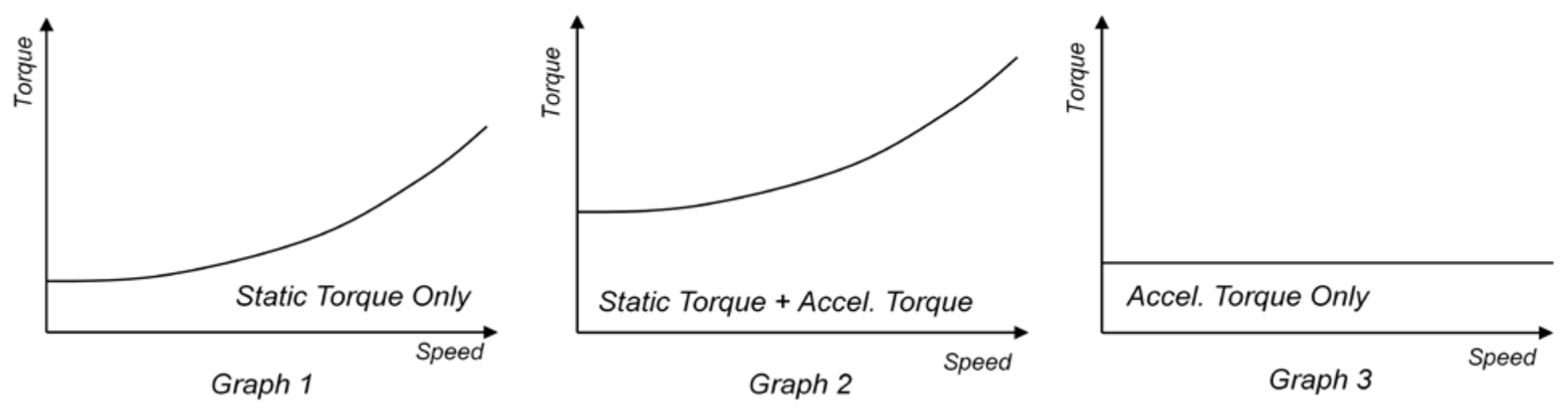

- Spin the motor up to a low speed and allow it to settle (so that inertia torque equals zero). Then take a reading of the average motor torque (Figure 12-17).

- Repeat step 3 at successively higher speeds, and generate a graph of average torque readings as a function of speed (Graph 1). Record the average current required for the highest speed setting. Then turn off the motor and allow it to stop.

- Disable the speed loop and using current mode only, apply about 1.2x to 1.5x the current from step 4 to the motor. As the speed hits each speed for which a torque value was recorded in step 4, record the torque again (Graph 2), and also take a time stamp.

- Subtract graph 1 from graph 2 (this should be the acceleration torque only) (Graph 3).

- For each point in graph 3, calculate the delta speed and delta time between the points before and after the target point. Divide delta speed by delta time to get the local acceleration value for that point.

- For each torque value in graph 3, divide it by the local acceleration for that point from step 7, to create a graph of inertia (J) as a function of speed.

- Average the inertia values at different speeds to obtain a single estimate for system inertia.

This process can be done a priori on a bench dynamometer test, or, if there is a way to measure torque in the control algorithm such as the torque output of InstaSPIN-FOC, this can be done as part of the commissioning process of the motor in its target application.

Up to now, we have only discussed PI tuning in generic terms which are independent of the control topology. In the next section, we will focus on some of the subtle points to consider when designing PI controllers for use in a Field-Oriented Control (FOC) system.

Figure 11-17 Average Motor Torque Readings

Figure 11-17 Average Motor Torque Readings