SPRADE9 November 2023 AM2431 , AM2432 , AM2434 , AM623 , AM625 , AM625-Q1 , AM625SIP , AM62A1-Q1 , AM62A3 , AM62A3-Q1 , AM62A7 , AM62A7-Q1 , AM62P-Q1 , AM6411 , AM6412 , AM6421 , AM6422 , AM6441 , AM6442 , AM6526 , AM6528 , AM6546 , AM6548 , AM67 , AM67A , AM68 , AM68A , AM69 , AM69A , DRA821U , DRA821U-Q1 , DRA829J , DRA829J-Q1 , DRA829V , DRA829V-Q1

1 Introduction

Industrial control requires real-time communication with deterministic latency. The technologies used have evolved from serial field buses to industrial Ethernet protocols defined in IEC standards such as EtherCAT, EtherNet/IP™ and PROFINET. These standards use parts of IEEE Ethernet to leverage some of the economies of scale that Ethernet offers, but they add small changes like cut-through switching that go beyond and partially restrict the use of typical IEEE bridges and endpoints. Contrary to typical consumer or enterprise systems, where average responsiveness or throughput are key performance indicators, the performance of industrial control applications are bounded by the worst-case latency of interacting with inputs and outputs across the network.

IEEE 802.1Q-2018 introduced many of the Time Sensitive Networking (TSN) features to standard IEEE Ethernet that used to require an industrial Ethernet network. With technologies like OPC UA FX [1] and the TSN profile IEC/IEEE 60802 [2], it is envisioned that a local area network engineered with TSN features would enable the use of standard IEEE Ethernet hardware to implement the industrial control network. Although introduced several years ago [4], this technology is still a work in progress. It looks like in earlier versions of this technology, the target is controller to controller communication, and thus co-existing with existing technologies. It is also worth noting that the existing industrial Ethernet technologies are still growing and are the backbone of modern factory automation.

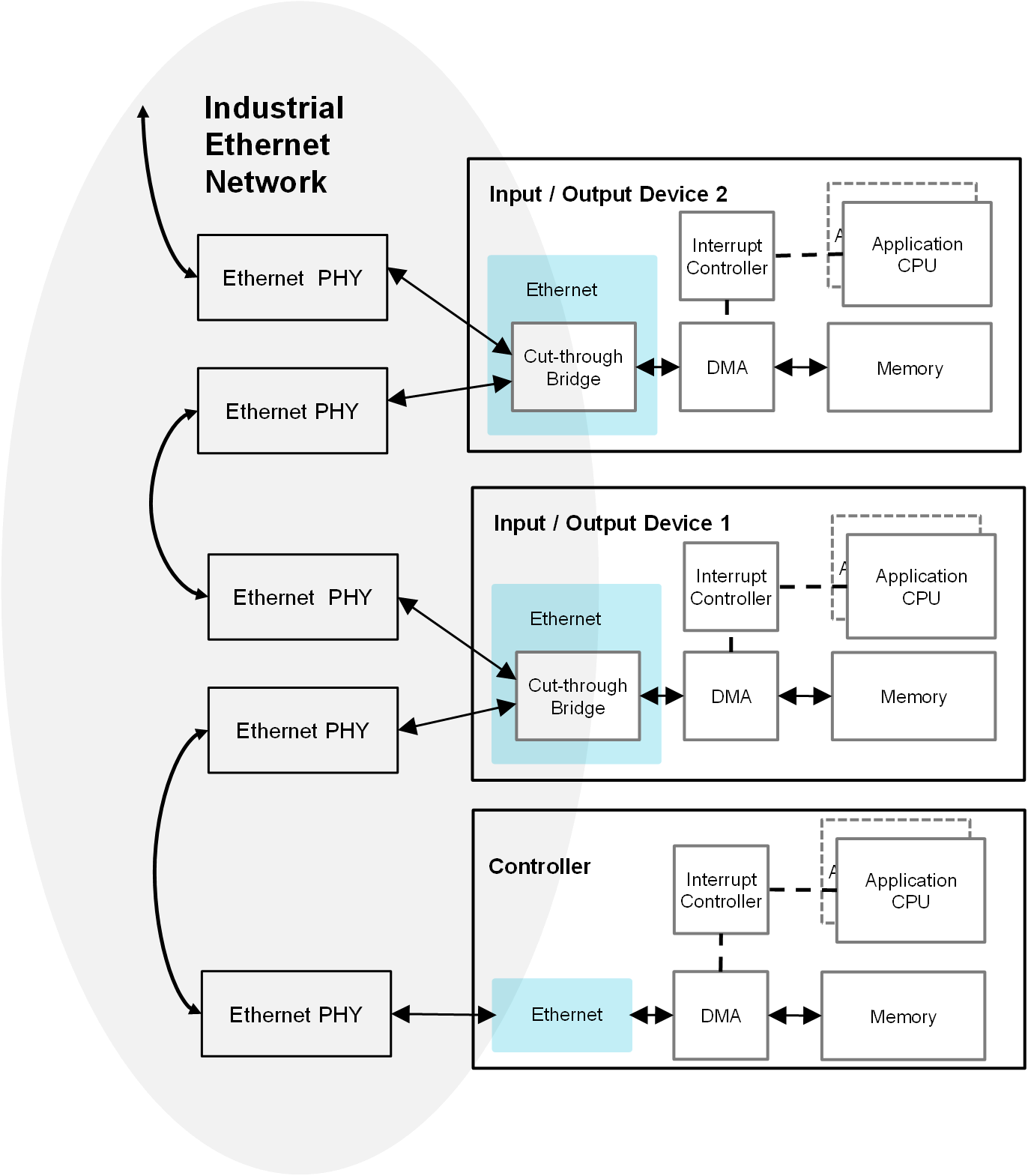

Regardless of the transition, the typical industrial topology remains the same as shown in Figure 1-1. Generally, Ethernet, including TSN, specifies layers 1 and 2 of the local area network (LAN). This allows for stateless and unreliable transmission of variable-sized frames from one endpoint to another endpoint and the switching in between. This domain is shown shaded in light gray in Figure 1-1. The protocol on top, such as EtherCAT, is highly asymmetric; there is one controller managing a few or even hundreds of devices. Each of the protocols uses slightly different terminology for this asymmetric relationship, and there are varying levels of this asymmetry. Similar to other engineering specifications, the terminology is in transition as some have found it offensive [3]. The term “controller” for the managing entity and “device” for what is generally being controlled is used in this document. Specifically with EtherCAT, the terms “main” and “subordinate” will be used.

This application note features a comparison of standard TSN feature of EST and established industrial Ethernet technologies to show the optimization of the controller's performance.

Figure 1-1 A Typical Industrial Ethernet

Network

Figure 1-1 A Typical Industrial Ethernet

Network