SPRACM9B June 2019 – November 2020 F29H850TU , F29H859TU-Q1 , TMS320F28384D , TMS320F28384S , TMS320F28386D , TMS320F28386S , TMS320F28388D , TMS320F28388S , TMS320F28P650DH , TMS320F28P650DK , TMS320F28P650SH , TMS320F28P650SK , TMS320F28P659DH-Q1 , TMS320F28P659DK-Q1 , TMS320F28P659SH-Q1

- Trademarks

- 1 Introduction

- 2 Benefits of the TMS320F2838x MCU for High-Bandwidth Current Loop

- 3 Current Loops in Servo Drives

- 4 Outline of the Fast Current Loop Library

- 5 Fast Current Loop Evaluation

- 6 Incremental Build Level 1

- 7 Incremental Build Level 2

- 8 Incremental Build Level 3

- 9 Incremental Build Level 4

- 10Incremental Build Level 5

- 11Incremental Build Level 6

- 12Incremental Build Level 7

- 13Incremental Build Level 8

- 14References

- 15Revision History

11.4 Setting Up the GUIs to Connect to Target Platform

Both GUIs have identical procedures to connect to the target platform. The GUI lets you select appropriate settings based on the target platform and development computer.

The following is a list of things to do on the GUI before starting the analysis:

- Math Mode: Depending on the target C2000 development platform, either the fixed point or floating point option is chosen. For F2837x or later C2000 MCUs, select the ‘Floating Point’ option

- Since the USB port on the control card / launch pad is already connected to the computer for JTAG purposes, no additional connection is required. However, for a standalone operation, an USB connector needs to be connected to the target board. In the XDS100 emulator present on the control card / launch pad, in addition to a JTAG link, an SCI port link is also provided and the GUI uses this link to connect to the SCI port of the target platform. While the debug environment of CCS is using JTAG, the GUI can also use SCI at the same time.

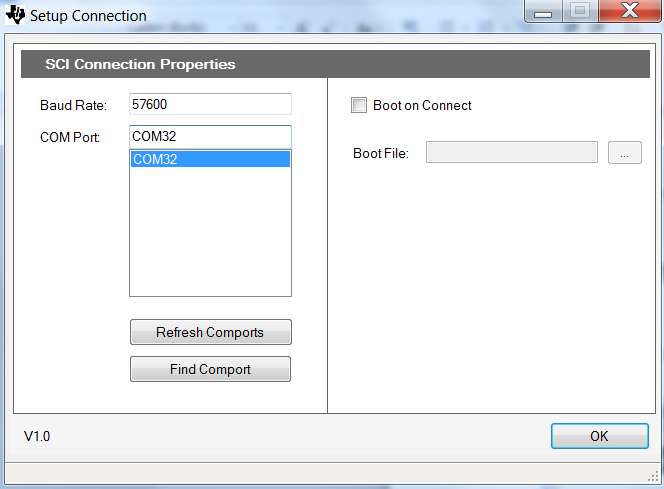

- Click on the Setup button at the bottom right corner. This will pop open a Setup Connection window as shown in Figure 11-4.

Figure 11-4 GUI Setup Diagram

Figure 11-4 GUI Setup Diagram - Click ‘Refresh Comports’ button to get the Comport number show up in the window.

- Select the Comport representing the connection to the target C2000 board.

- Uncheck ‘Boot on Connect’

- Click OK button

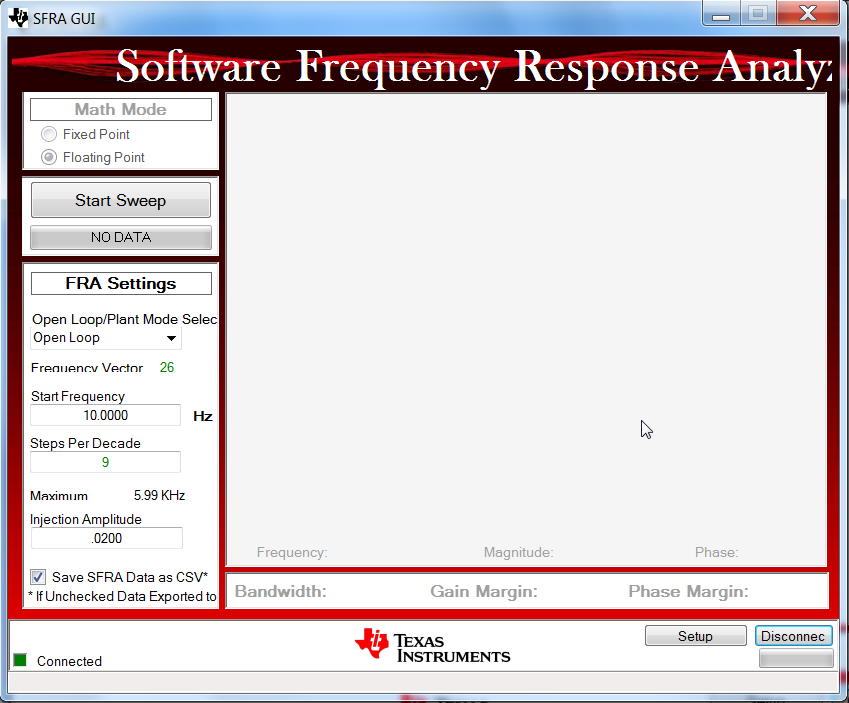

- This should establish the connection to the MCU control card/launchpad and the GUI will appear as shown in Figure 11-5 indicating the connection status at the bottom left corner.

Figure 11-5 SFRA GUI Connected to the C2000 MCU

Figure 11-5 SFRA GUI Connected to the C2000 MCU - The frequency sweep related settings are shown in ‘FRA Settings’ Panel. These values are already pre-filled from the C2000 device and they can be left as is.

- As mentioned earlier, the visual difference between the two GUIs is in the pull down menu under 'FRA Settings' starting with Open Loop.

- In the SFRA_GUI, this pull down menu helps to select between Open Loop Model and Plant Model

- In the SFRA_GUI_MC, this pull down menu helps to select between Open Loop Model and Closed Loop Model

- This menu becomes relevant after a complete noise injection sweep of the system at various frequencies. Then, you can pick and view the plot of choice using this menu.

- Bandwidth reporting is different as mentioned earlier. Gain cross over frequency is reported in the open loop plot of the SFRA_GUI_MC instead of bandwidth as in SFRA_GUI.

This completes the initial setup of GUI environment.