SPRACM9B June 2019 – November 2020 F29H850TU , F29H859TU-Q1 , TMS320F28384D , TMS320F28384S , TMS320F28386D , TMS320F28386S , TMS320F28388D , TMS320F28388S , TMS320F28P650DH , TMS320F28P650DK , TMS320F28P650SH , TMS320F28P650SK , TMS320F28P659DH-Q1 , TMS320F28P659DK-Q1 , TMS320F28P659SH-Q1

- Trademarks

- 1 Introduction

- 2 Benefits of the TMS320F2838x MCU for High-Bandwidth Current Loop

- 3 Current Loops in Servo Drives

- 4 Outline of the Fast Current Loop Library

- 5 Fast Current Loop Evaluation

- 6 Incremental Build Level 1

- 7 Incremental Build Level 2

- 8 Incremental Build Level 3

- 9 Incremental Build Level 4

- 10Incremental Build Level 5

- 11Incremental Build Level 6

- 12Incremental Build Level 7

- 13Incremental Build Level 8

- 14References

- 15Revision History

12.5 Program ControlCard EEPROM for ESC

Verify first that TwinCAT has discovered the ESC as described in Section 12.4. Also, make sure to copy the ESC XML file into TwinCAT directory before starting off to program the EEPROM.

- Copy the ESI file (F2838x CM EtherCAT Slave (System).xml available at \solutions\tmdxiddk379d\f2838x\ssc_configuration) into the TwinCAT directory (Default location: C:\TwinCAT\3.1\Config\Io\EtherCAT). If TwinCAT was already open, it has to be closed and re-opened again for it to see new XML file(s).

- In the Visual Studio solution explorer, double click on Box # under Device 2 (EtherCAT).

- The TwinCAT project window should be open to the right of the solution explorer and have some tabs such as General, EtherCAT, and so forth

- Select the EtherCAT tab and then click on Advanced Settings

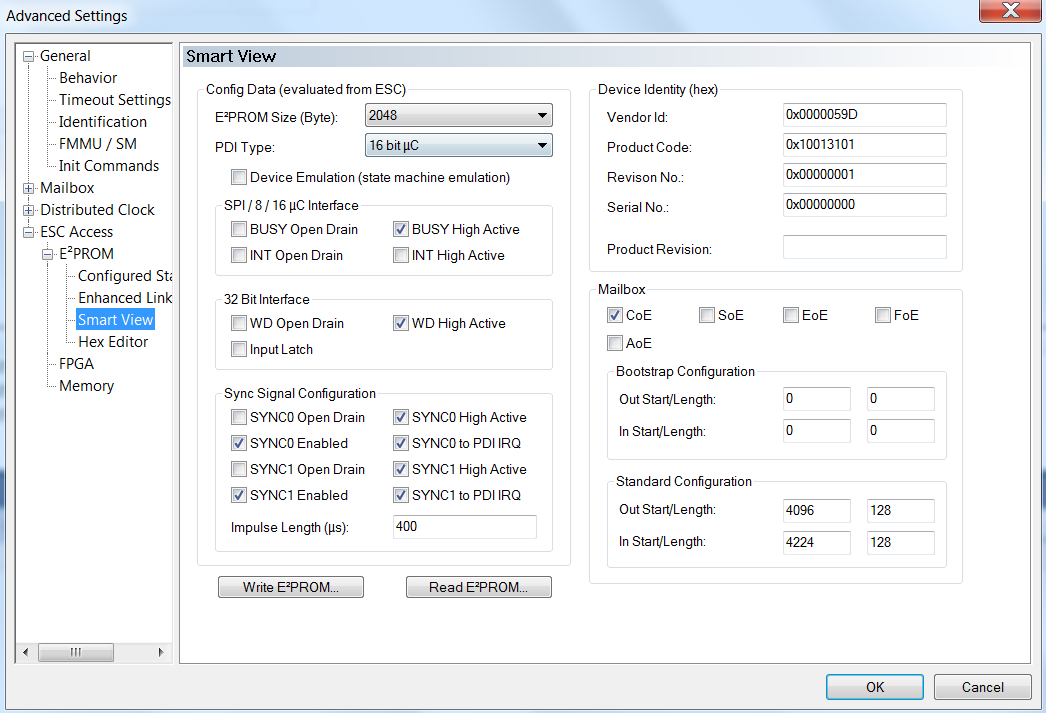

- In the new window, expand the ESC Access menu, then expand the E2PROM menu. Click on Smart View

- Click on Write E2PROM and expand the Texas Instruments Incorporated menu within the Available EEPROM Descriptions window.

- Expand TI C28xx Slave Devices and select F2838x CM EtherCAT Slave. Click OK.

- Visual Studio will indicate that the EEPROM is being programmed. When it completes, if the Smart View doesn’t automatically update with the new contents, you can select Read E2PROM to read back the newly programmed values.

- The Product Code for this CM application is 0x10003101

- Once EEPROM is programmed, disconnect and power cycle the controller.

Figure 12-4 TwinCAT EEPROM Window

Figure 12-4 TwinCAT EEPROM Window